Method of preparing second-order non-linear optical materials, and uses thereof

A second-order nonlinear and optical crystal technology, applied in the fields of materials science and inorganic chemistry, can solve the problems of no ideal method for large-size single crystals, difficulty in obtaining pure products, and limited material applications, etc., to achieve mild conditions and high product purity , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

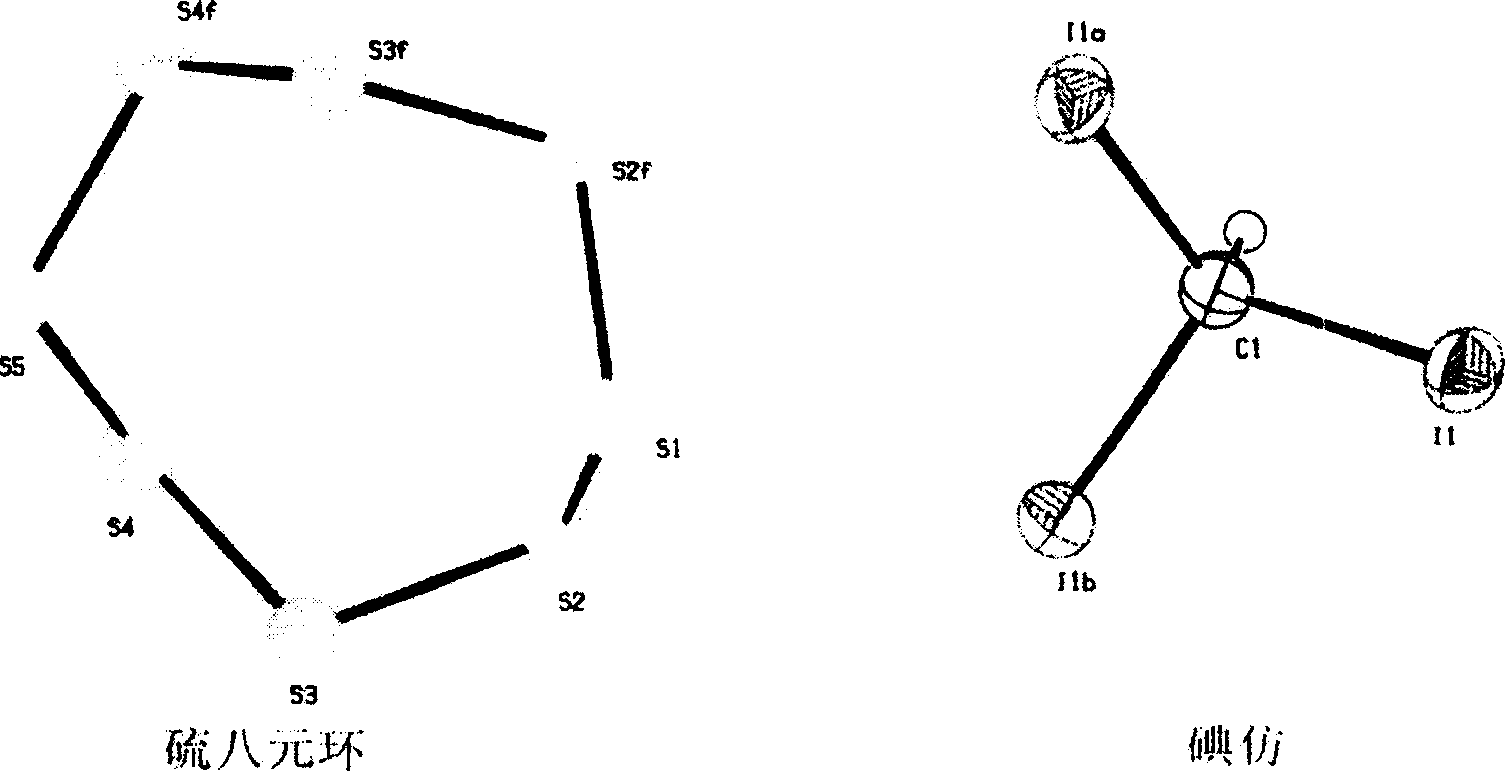

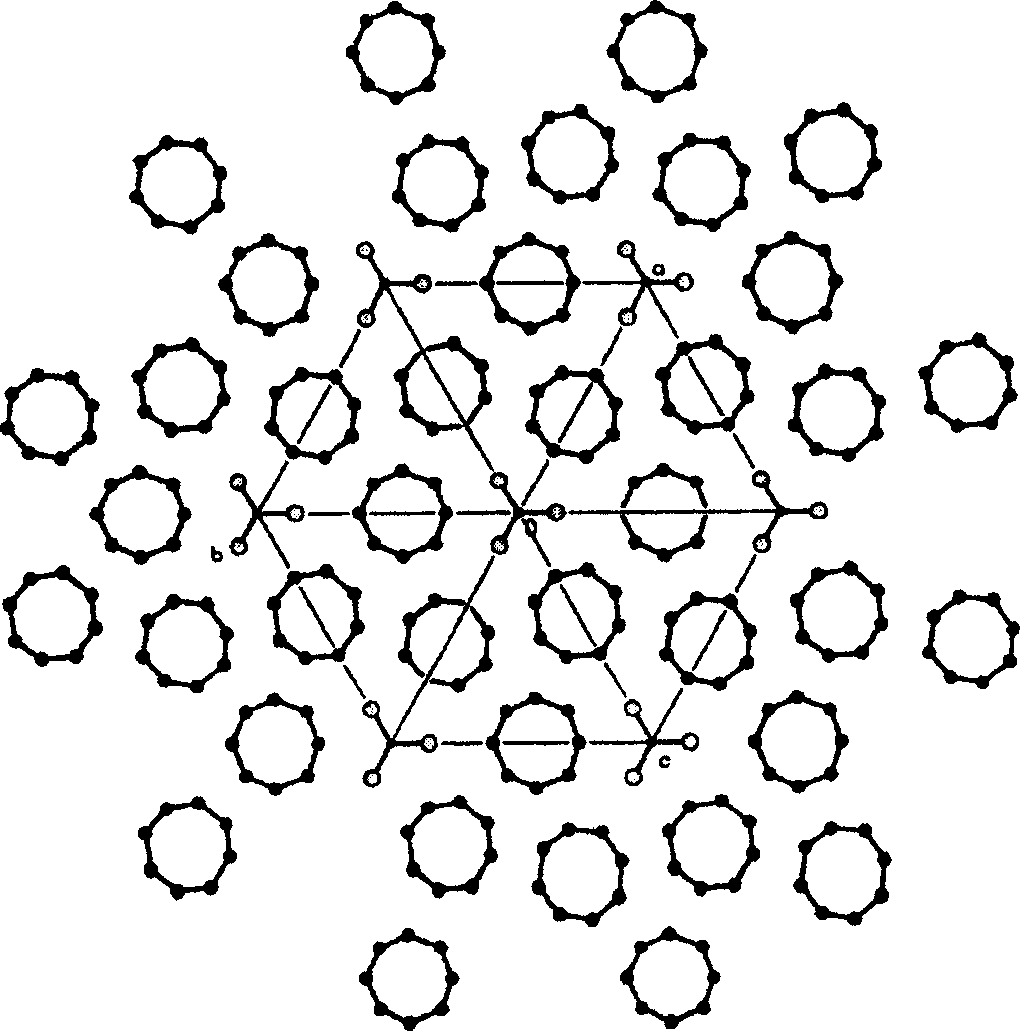

[0031] Preparation of second-order nonlinear optical crystal materials:

[0032] 1) 1.5748 grams of iodoform (40 mmol) and 1.066 grams of sulfur powder (0.12 moles) are placed in a polytetrafluoroethylene reactor (about 20 milliliters in volume) with a stainless steel jacket, and about 12 milliliters (can be 13 . (could be 20, 22, 26, 28, 32, 35 hours). Cool down naturally, filter quickly, and rinse the filter cake with a large amount of carbon disulfide solvent to obtain a large amount of purple-red solution, which is the carbon disulfide solution of the second-order nonlinear optical crystal material.

[0033] 2) Put the obtained carbon disulfide solution of the second-order nonlinear optical crystal material in a round-bottomed flask (can be a container such as a flat-bottomed flask, an Erlenmeyer flask), connect a drying tube to the mouth of the bottle, and place it at 10°C (can be 11 , 12, 13, 14, 15°C) in a constant temperature water tank, let it stand still, let the s...

Embodiment 2

[0035] Preparation of second-order nonlinear optical crystal materials:

[0036] 1) 1.5748 grams of iodoform (40 mmoles) and 1.244 grams of sulfur powder (0.14 moles) are placed in a polytetrafluoroethylene reactor (about 20 milliliters in volume) with a stainless steel jacket, and about 12 milliliters (can be 13 . (could be 20, 22, 26, 28, 32, 35 hours). Cool down naturally, filter quickly, and rinse the filter cake with a large amount of carbon disulfide solvent to obtain a large amount of purple-red solution, which is the carbon disulfide solution of the second-order nonlinear optical crystal material.

[0037]2) Put the obtained carbon disulfide solution of the second-order nonlinear optical crystal material in a round-bottomed flask (can be a container such as a flat-bottomed flask, an Erlenmeyer flask), connect a drying tube to the mouth of the bottle, and place it at 10°C (can be 11 , 12, 13, 14, 15°C) in a constant temperature water tank, let it stand still, let the ...

Embodiment 3

[0039] Preparation of second-order nonlinear optical crystal materials:

[0040] 1) 1.5748 grams of iodoform (40 mmol) and 1.421 grams of sulfur powder (0.16 moles) are placed in a polytetrafluoroethylene reactor (about 20 milliliters in volume) with a stainless steel jacket, and about 12 milliliters (which can be 1 3, 14, 15, 16 milliliters) of carbon disulfide, sealed with a stainless steel jacket, put into a hydrothermal reactor, and react at a constant temperature of 65°C (60, 62, 68, 70, 72, 75, 78, and 80°C) for 30 Hours (could be 20, 22, 26, 28, 32, 35 hours). Cool down naturally, filter quickly, and rinse the filter cake with a large amount of carbon disulfide solvent to obtain a large amount of purple-red solution, which is the carbon disulfide solution of the second-order nonlinear optical crystal material.

[0041] 2) Put the obtained carbon disulfide solution of the second-order nonlinear optical crystal material in a round-bottomed flask (can be a container such ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com