Compoiste film for lens

A composite film and film technology, applied in glasses/goggles, synthetic resin layered products, optics, etc., can solve the problems of poor composite performance of cellulose triacetate, more expensive finished glasses, and poor surface hardness, etc. Achieve the effect of easy polarization processing, low cost and stable geometric size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example B

[0026] Name Weight percentage content (%)

[0027] Triacrylate 20~30 Tetraacrylate 20~30

[0028] Acetone 10~20 Methanol 5~10

[0029] Butanone 15~25 nanometer alumina (50-100nm) 0.5~2.5

[0030] The acrylate of the hardening layer also includes ethoxytrimethylpropane triacrylate, dimethoxypropane tetraacrylate, pentaerythritol triacrylate, ethoxypentaerythritol triacrylate, etc., which can be dissolved in the solvent of the above ratio .

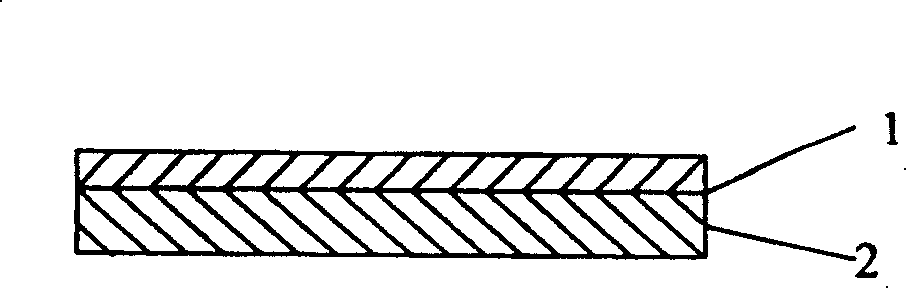

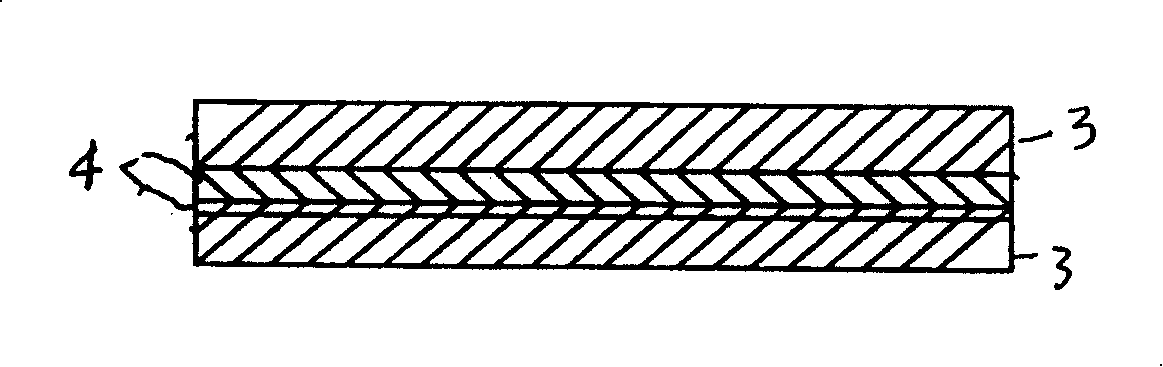

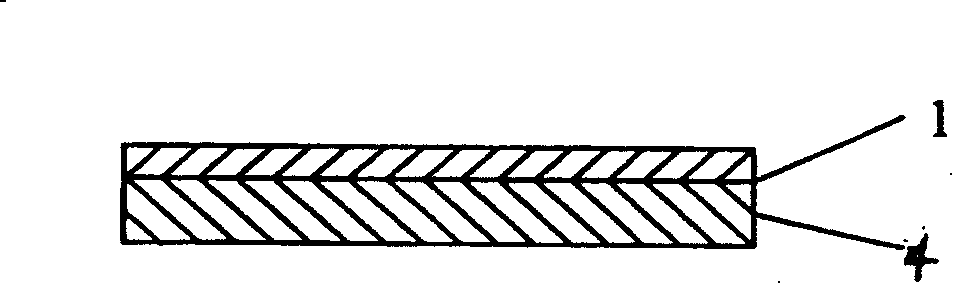

[0031] Cellulose triacetate composite film of the present invention is specially used in making CR-39 resin polarized spectacle lens after polarizing treatment (see figure 2 ) and the manufacture of ultra-thin polarized dark lenses (see image 3 ).

[0032] figure 2 As shown, the surface can be infused with CR-39 resin after being coated with affinity cellulose butylacetate and then treated with polarizing light to become the base material of high-grade spectacle lenses.

[0033] image 3 The medium polarized PVA film is directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com