Equipment and process for preparing monocrystalline GaN film material

A gallium nitride single crystal and thin film material technology, which is applied in polycrystalline material growth, chemical instruments and methods, single crystal growth, etc., can solve the problem of difficulty in ensuring the quality of gallium nitride thin film, inability to mix raw materials and gases uniformly, and unreasonable structure and other problems, to achieve the effect of saving raw material gas, stable operation, uniform mixing and sufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

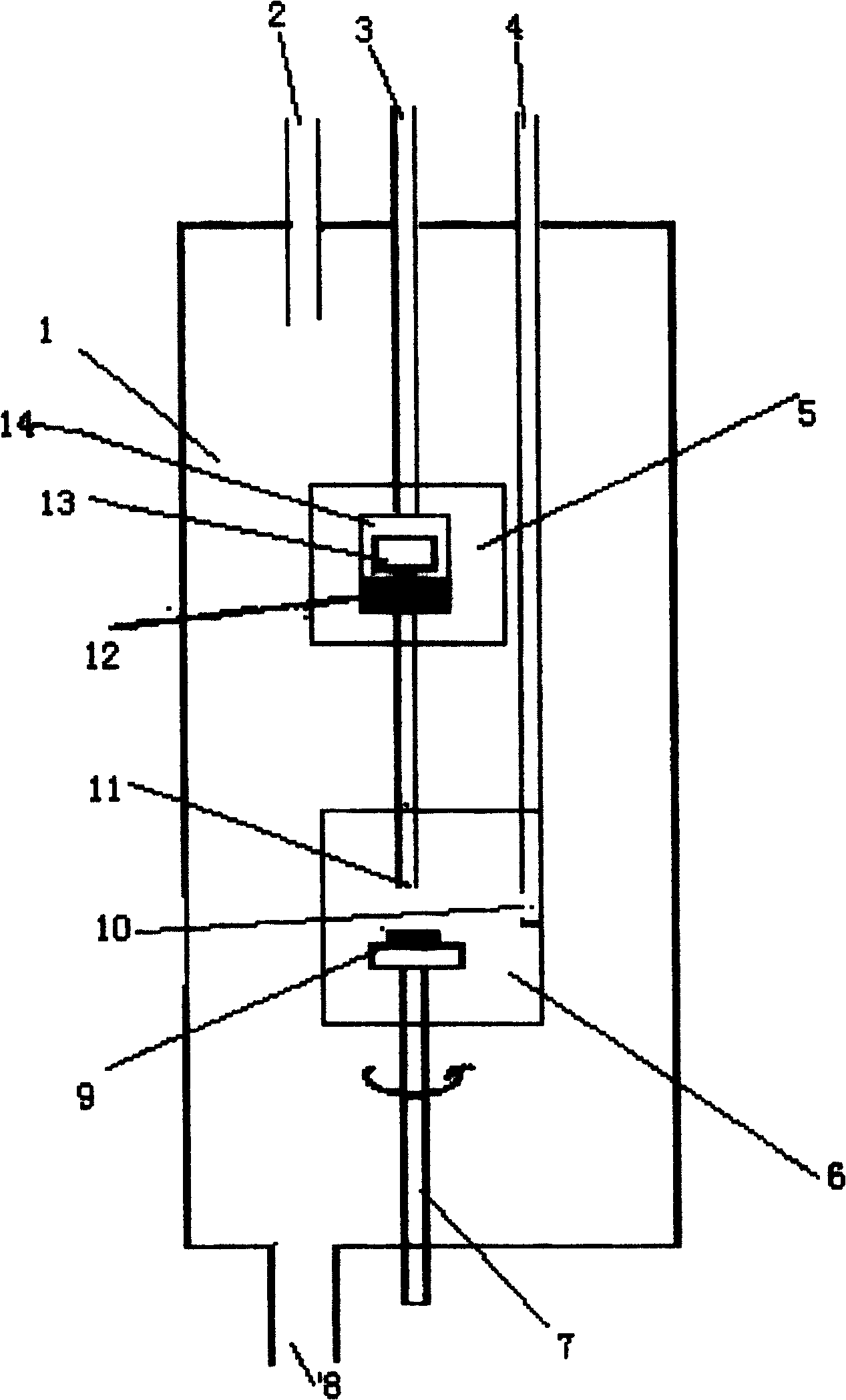

Method used

Image

Examples

Embodiment 1

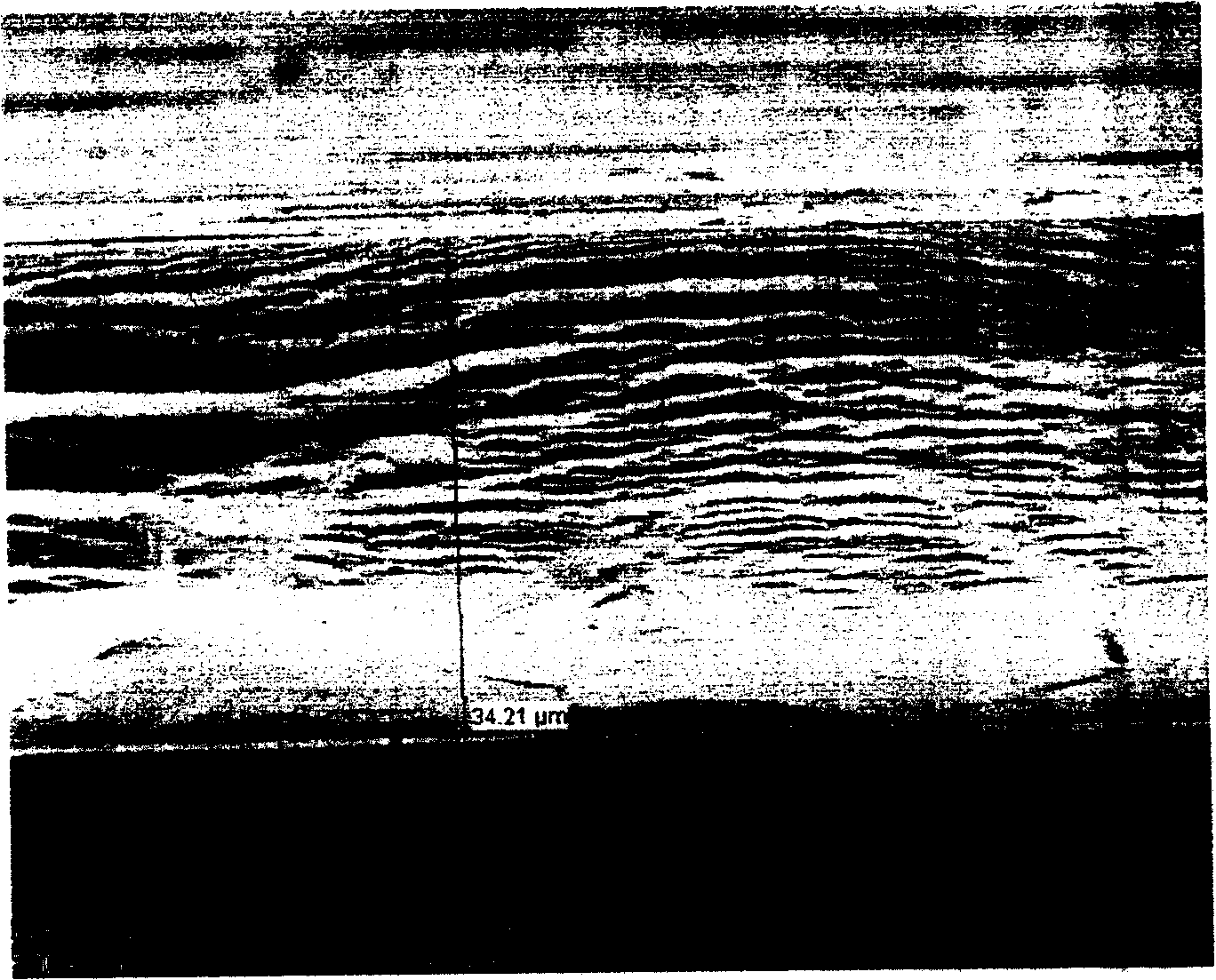

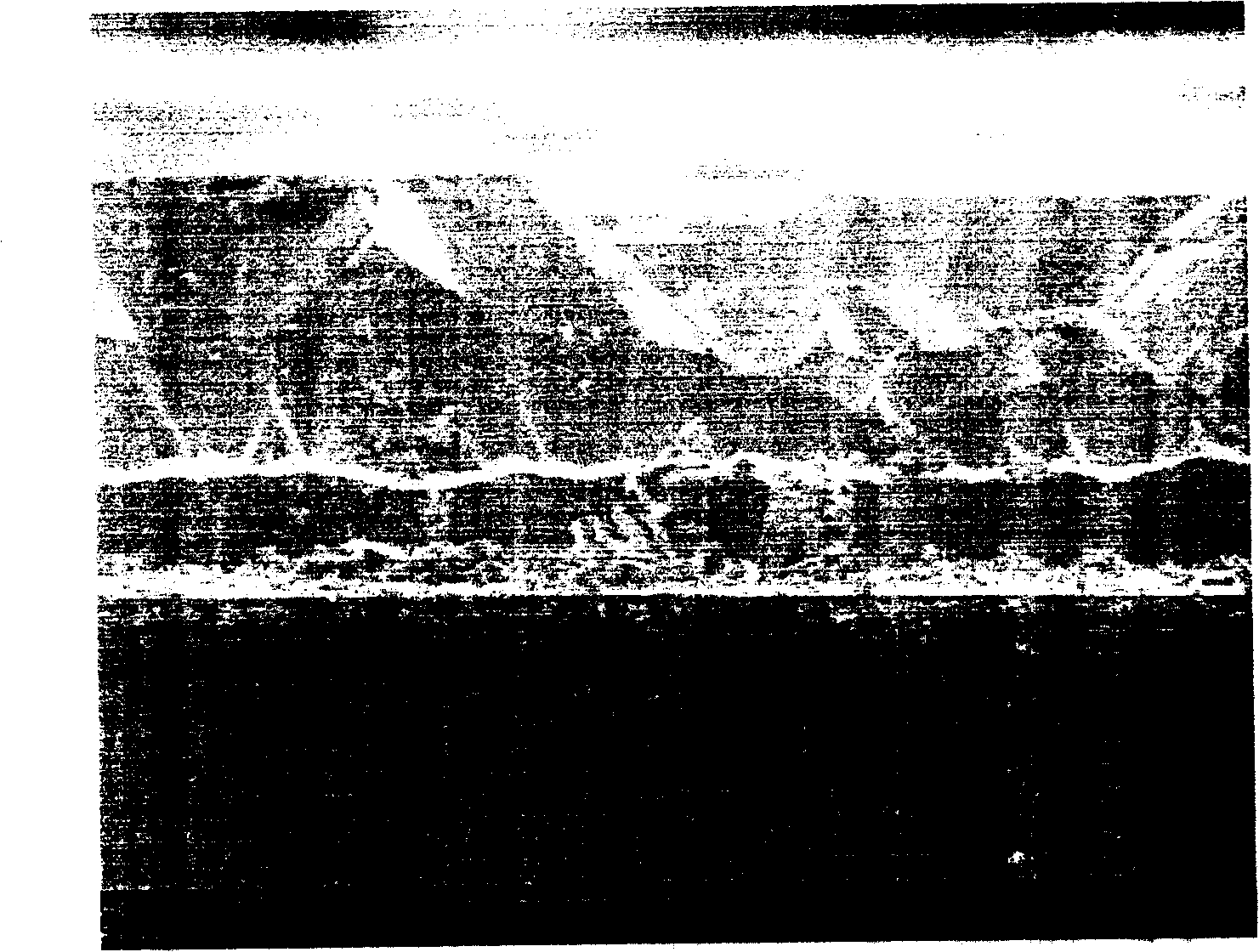

[0017]Example 1: The preparation is completed according to the following steps: a) First, the sapphire substrate covered with aluminum nitride film and gallium nitride film is washed with acetone and ethanol in an ultrasonic bath for two consecutive times for 10 minutes, and then used Rinse with ionized water for 3 minutes and blow dry with purified nitrogen. Then, it is placed on the support frame in the vacuum chamber, and the vacuum chamber is placed under a nitrogen atmosphere, and the vacuum degree of the vacuum chamber under the nitrogen atmosphere is ≤1 atmospheric pressure; wherein the nitrogen gas flow rate is 600 sccm. b) Raise the temperature of the source area and the growth area to 500°C for 3 hours, while continuing to pass nitrogen gas with a flow of 600sccm into the vacuum chamber, then pass ammonia gas and its carrier with a flow of 300sccm into the vacuum chamber. Nitrogen with a flow of 200sccm. Next, the temperature of the source zone was raised to 850°C, and t...

Embodiment 2

[0018] Example 2: The preparation is completed according to the following steps: a) First, the sapphire substrate covered with aluminum nitride film and gallium nitride film is washed with acetone and ethanol in an ultrasonic bath for two consecutive times for 10 minutes, and then used Rinse with ionized water for 3 minutes and blow dry with purified nitrogen. Then, it is placed on the support frame in the vacuum chamber, and the vacuum chamber is placed under a nitrogen atmosphere, and the vacuum degree of the vacuum chamber under the nitrogen atmosphere is ≤ 1 atmosphere; wherein the flow rate of nitrogen is 1200 sccm. b) Raise the temperature of the source area and the growth area to 515°C for 2.9 hours. While continuing to pass nitrogen with a flow of 1200sccm into the vacuum chamber, then pass ammonia and its carrier with a flow of 390sccm into the vacuum chamber. Nitrogen at a flow rate of 290sccm. Next, the temperature of the source zone was raised to 865°C, and the tempera...

Embodiment 3

[0019] Example 3: The preparation is completed according to the following steps: a) First, the sapphire substrate covered with aluminum nitride film and gallium nitride film is washed with acetone and ethanol in an ultrasonic bath for two consecutive times for 10 minutes, and then used Rinse with ionized water for 3 minutes and blow dry with purified nitrogen. Then, it is placed on the support frame in the vacuum chamber, and the vacuum chamber is placed under a nitrogen atmosphere, and the vacuum degree of the vacuum chamber under the nitrogen atmosphere is ≤1 atmosphere; wherein the flow rate of nitrogen is 1800 sccm. b) Raise the temperature of the source area and the growth area to 530°C for 2.8 hours. While continuing to pass nitrogen at a flow rate of 1800sccm into the vacuum chamber, pass ammonia and its carrier at a flow rate of 450sccm into the vacuum chamber. Nitrogen at 350sccm flow rate. Next, the temperature of the source zone was raised to 880°C, and the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com