Method for preparation of polyester magnetic composite microsphere capable of being biodegraded

A technology of magnetic composite microspheres and biodegradable polyesters, which is applied in the directions of non-active components of medical preparations, pharmaceutical formulations, etc., can solve the problem of wide particle size distribution, weak magnetic responsiveness and low magnetic content of magnetic polyester composite microspheres. and other problems, to achieve the effect of good biodegradability, good biocompatibility and high magnetic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

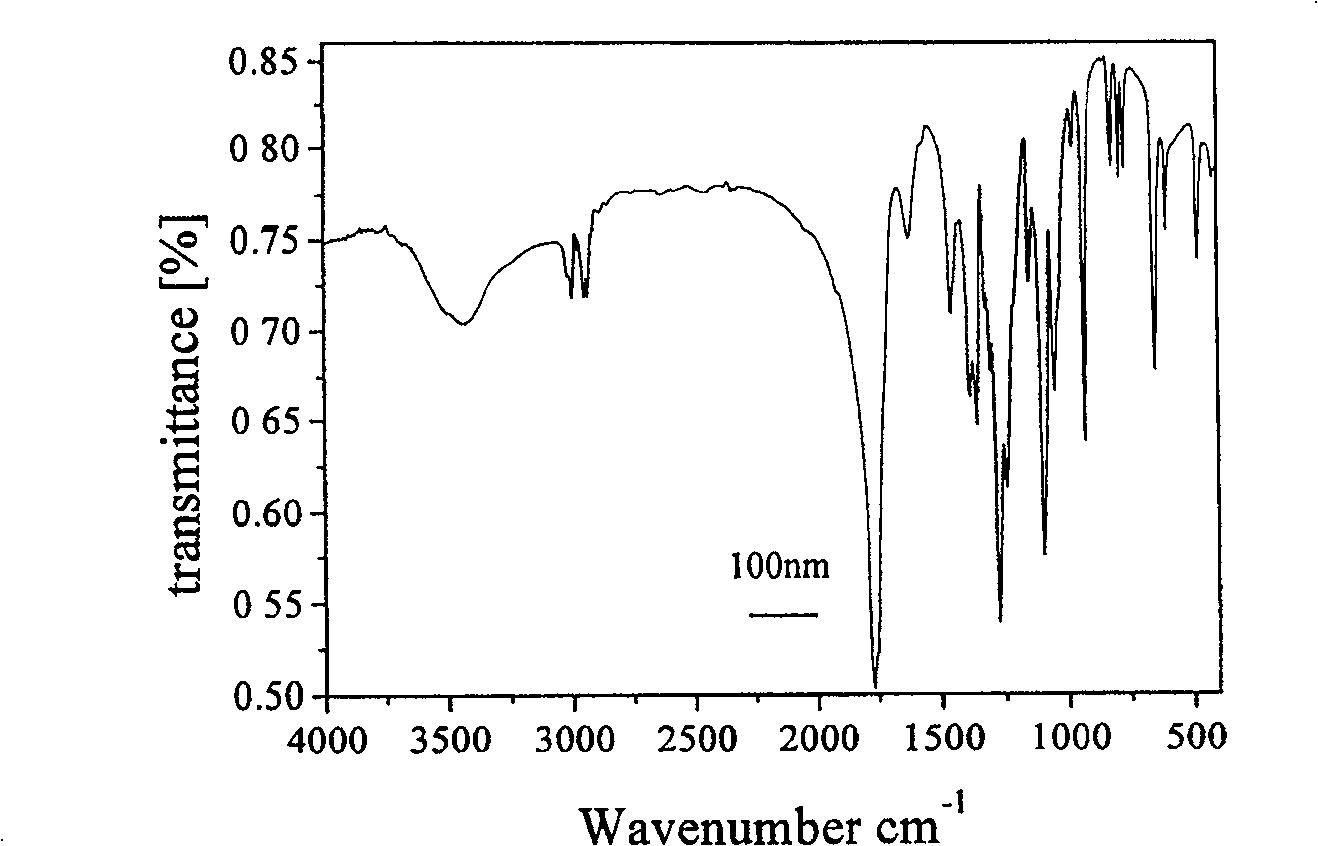

[0022] Embodiment 1: Lactic acid surface modification Fe 3 o 4 Nanoparticles

[0023] Add 0.5g Fe to the reaction flask 3 o 4 Particles and 40ml of dioxane are ultrasonically dispersed, and 10ml of lactic acid is slowly added dropwise under stirring. After the lactic acid is completely added, stir and react in a water bath at 40°C for 6 hours. After the product is cooled, it is magnetically separated and washed repeatedly with dioxane and ethanol. Vacuum freeze-drying at -50°C for 48 hours to obtain lactic acid surface-modified Fe 3 o 4 Nanoparticles.

Embodiment 2

[0024] Embodiment 2: Lactic acid surface modification Fe 3 o 4 Nanoparticles

[0025] Add 0.8g Fe to the reaction flask 3 o 4 Particles and 60ml tetrahydrofuran, ultrasonically dispersed, slowly add 15ml lactic acid dropwise under stirring state, after the lactic acid is completely added, N 2 Protected, stirred and reacted in a water bath at 50°C for 4h, the product was cooled and then magnetically separated, washed repeatedly with dioxane and ethanol, and vacuum freeze-dried at -50°C for 48h to obtain lactic acid surface-modified Fe 3 o 4 Nanoparticles.

Embodiment 3

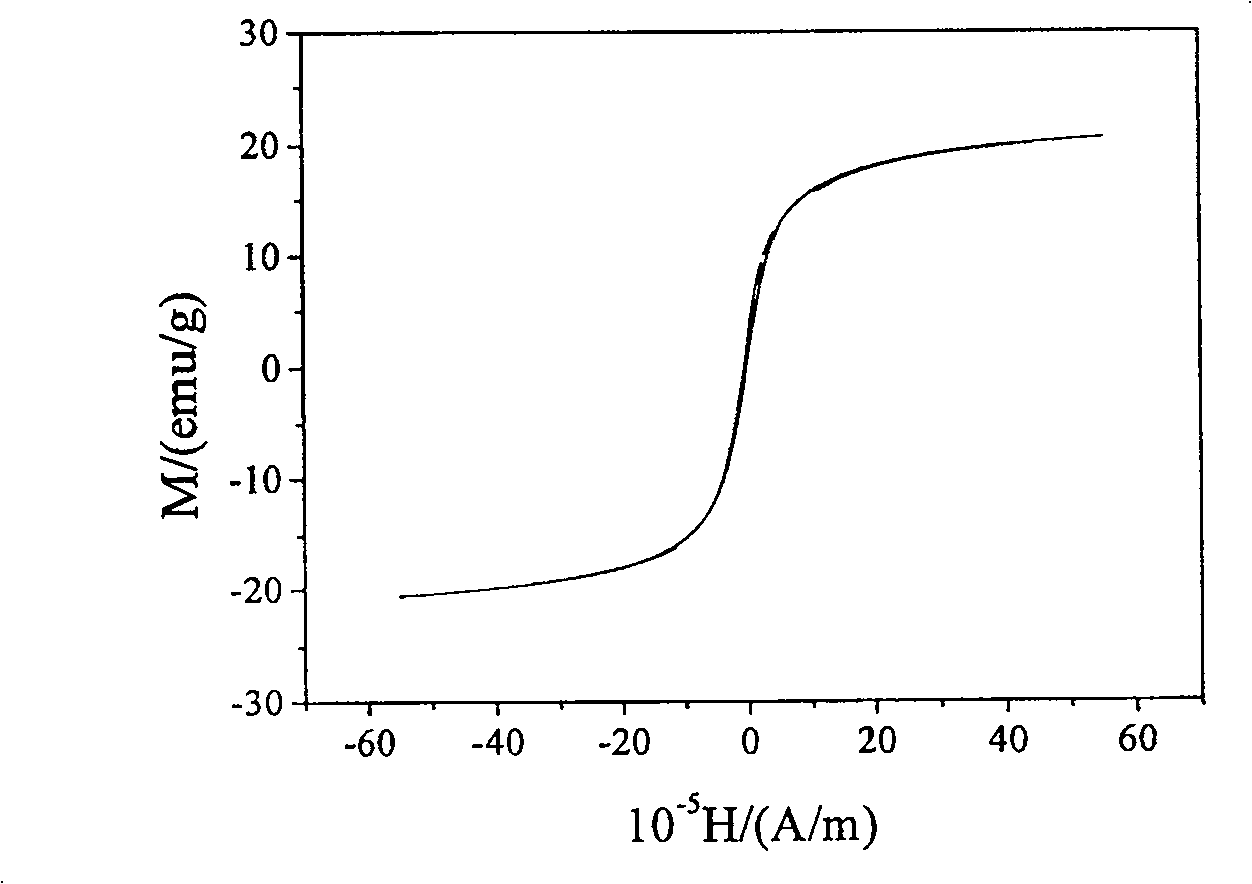

[0026] Example 3: Preparation of magnetic polyester composite microspheres by ring-opening polymerization of monomers on the surface of modified particles

[0027] 0.24g surface lactic acid modified Fe prepared in Example 1 3 o 4 The particles were ultrasonically dispersed in 60ml of xylene, 4.1g of lactide monomer and 15mg of stannous octoate catalyst were added, under anhydrous and anaerobic conditions, the reaction was stirred at 125°C for 48h, the product was magnetically separated, and the precipitate was washed repeatedly with xylene and ethanol , and then dialysis with 0.1mol / L HCl to remove uncoated Fe 3 o 4 Particles were finally washed with deionized water until neutral, and vacuum freeze-dried at -50°C for 48 hours to obtain a particle size of 130-320nm, Fe 3 o 4 The magnetic polyester composite microsphere with content of 27% and saturation magnetization of 20.7emu / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com