Organosilicon alcohol acid ready mixed paint coating composition and method of making the same

A technology of organosilicon and composition, which is applied in the field of metal surface coating paint composition and its preparation, can solve the problems that the comprehensive performance cannot meet the needs of the industry, affect metal protection and decoration, and easily warp the layer, etc., and achieve simple and easy operation Easy to use, short drying time, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

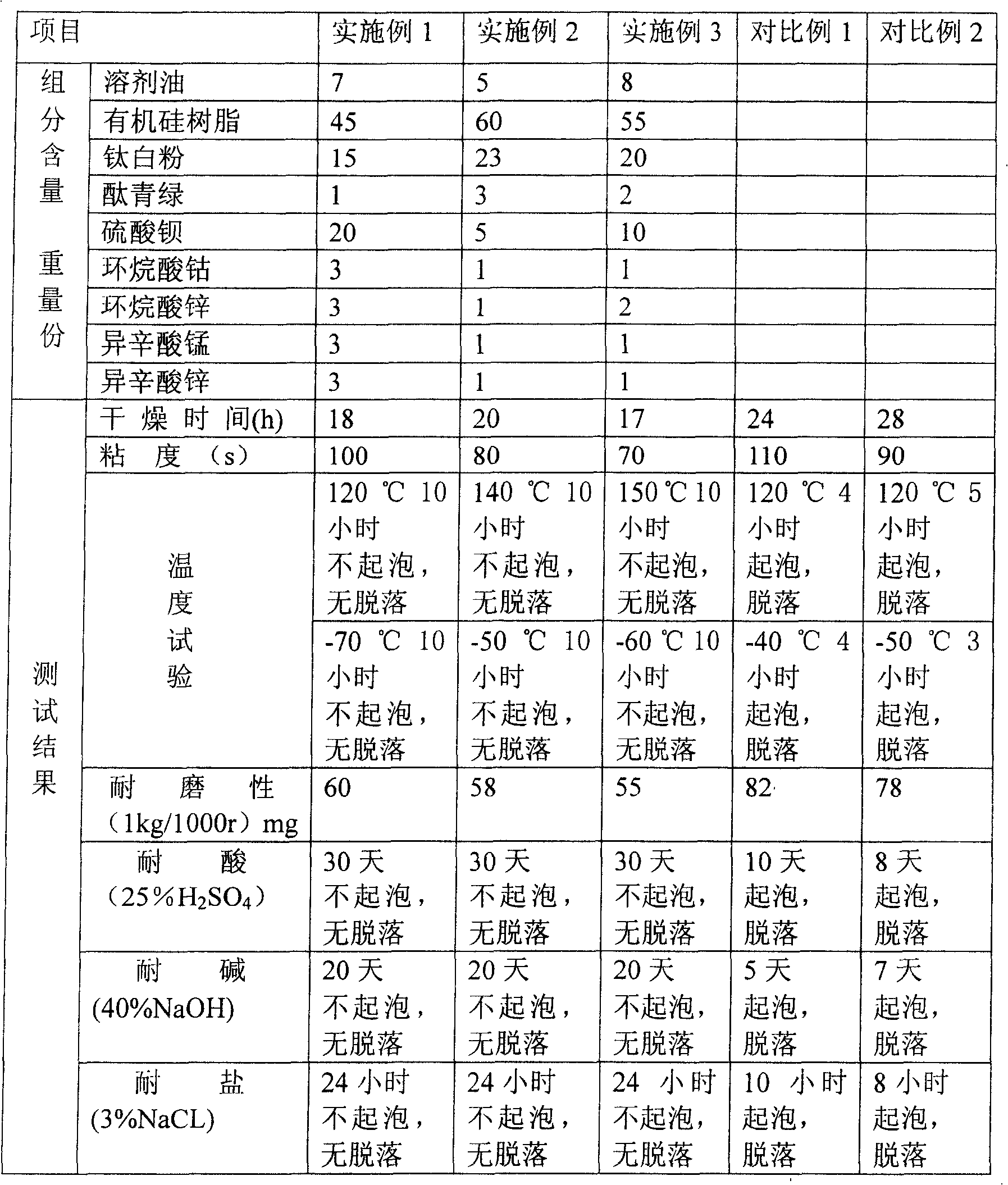

Embodiment 1

[0017] Under normal temperature and pressure, according to the dosage of each component specified in Table 1, put the mixture of titanium dioxide, phthalocyanine green, barium sulfate and silicone resin into a grinder and grind to a fineness of not more than 30 μm, add aromatic hydrocarbon No. 200 solvent oil Stir evenly to form a nail solution; add cobalt naphthenate, zinc naphthenate, manganese isooctanoate and zinc isooctanoate into the nail solution; stir and age for 1 hour to prepare a slurry coating composition. Viscosity was measured, and the coating composition was applied to a metal plate (the finish of the metal plate was Δ7) by spraying method to make a coating, which was dried under natural conditions of normal temperature and pressure, and then the drying time, heat resistance, Abrasion resistance, acid resistance, alkali resistance, salt resistance, oil resistance, performance at ambient temperature. The test results are shown in Table 1.

Embodiment 2

[0019] According to the consumption of each component specified in Table 1, the method of Example 1 was repeated, and No. 200 aromatic hydrocarbon solvent oil was used as the solvent oil. The test results are shown in Table 1.

Embodiment 3

[0021] According to the dosage of each component specified in Table 1, the method of Example 1 was repeated, but xylene was used for solvent oil. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com