Long-life alloy die-casting module and manufacturing method thereof

A manufacturing method and technology of die-casting molds, which are applied in the directions of manufacturing tools, heat treatment process control, furnace types, etc., can solve the problem that the microstructure does not have any refinement effect, the microstructure spheroidization effect is not good, and the uniformity of the structure and composition is not enough. and other problems, to achieve good high temperature tempering stability, fine microstructure, and segregation improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The weight percentage of the chemical composition of the module is: C 0.41wt%, Si 1.21wt%, Mn 0.50wt%, Cr 5.25wt%, V 1.10wt%, Mo 1.30wt%, S 0.0008wt%, P 0.010wt%, the rest is Fe and unavoidable impurities;

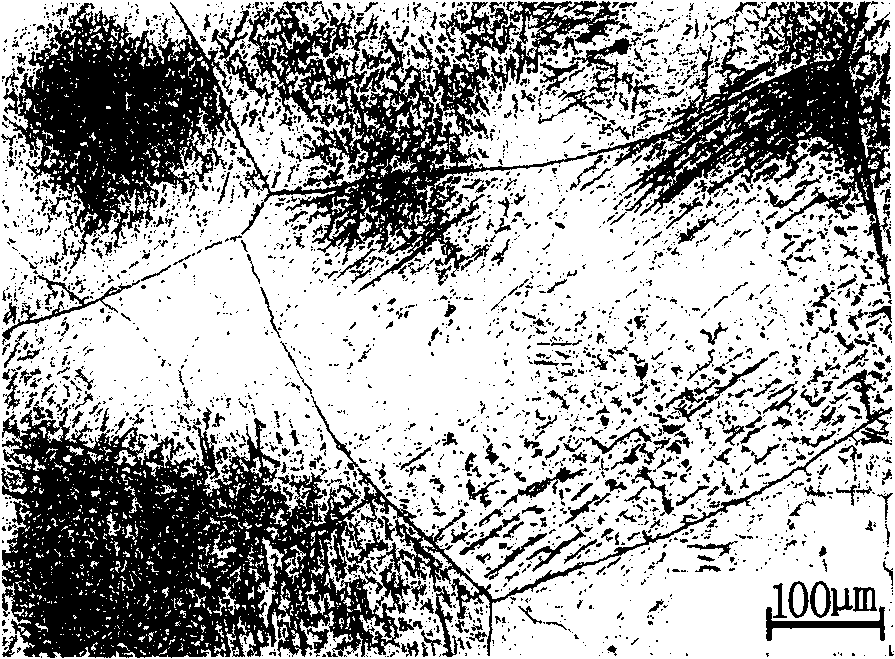

[0046] The electroslag ingot is kept in a heating furnace at a temperature of 1260°C for 19 hours for homogenization treatment. The photo of the metallographic structure after the homogenization treatment is shown in figure 1 ;

[0047] The electroslag ingot has undergone two upsetting and elongating treatments. The opening forging temperature is 1245°C and the final forging temperature is 890°C.

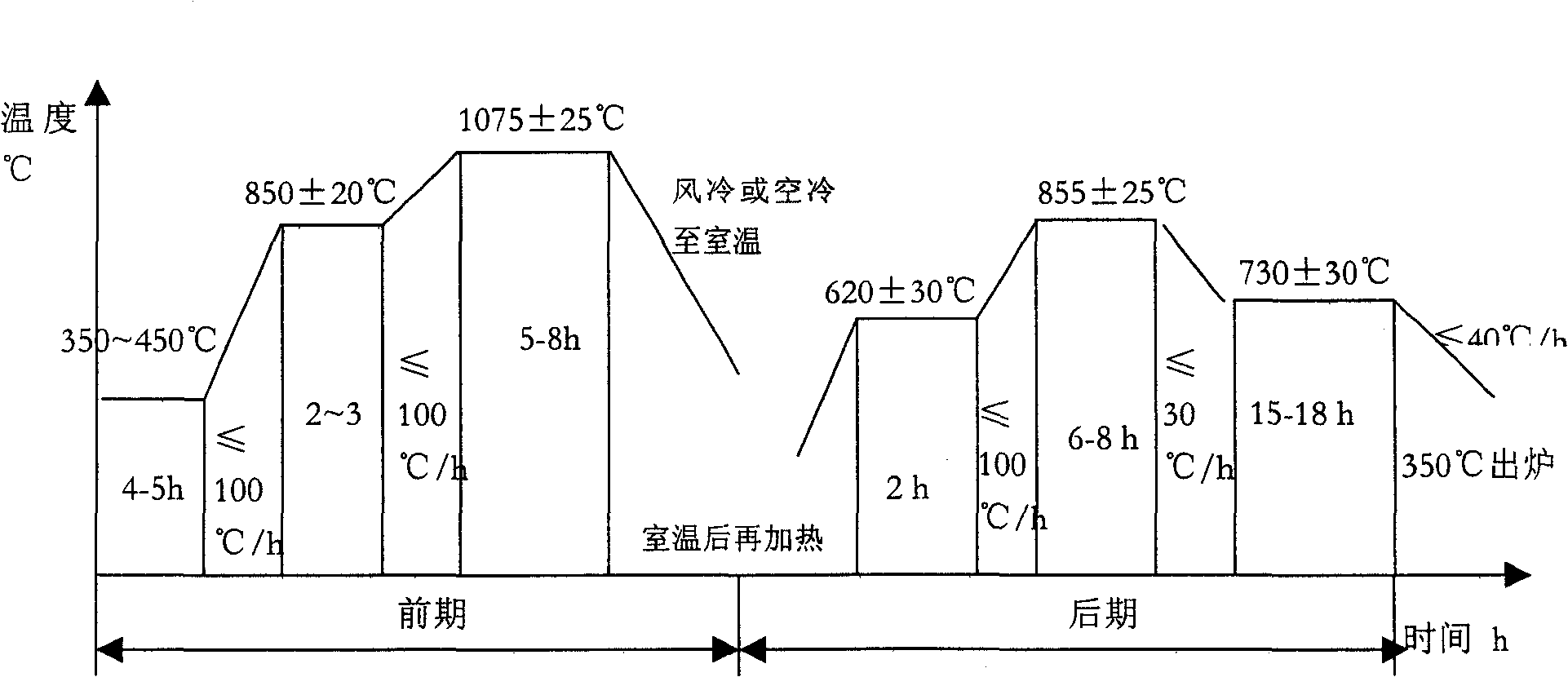

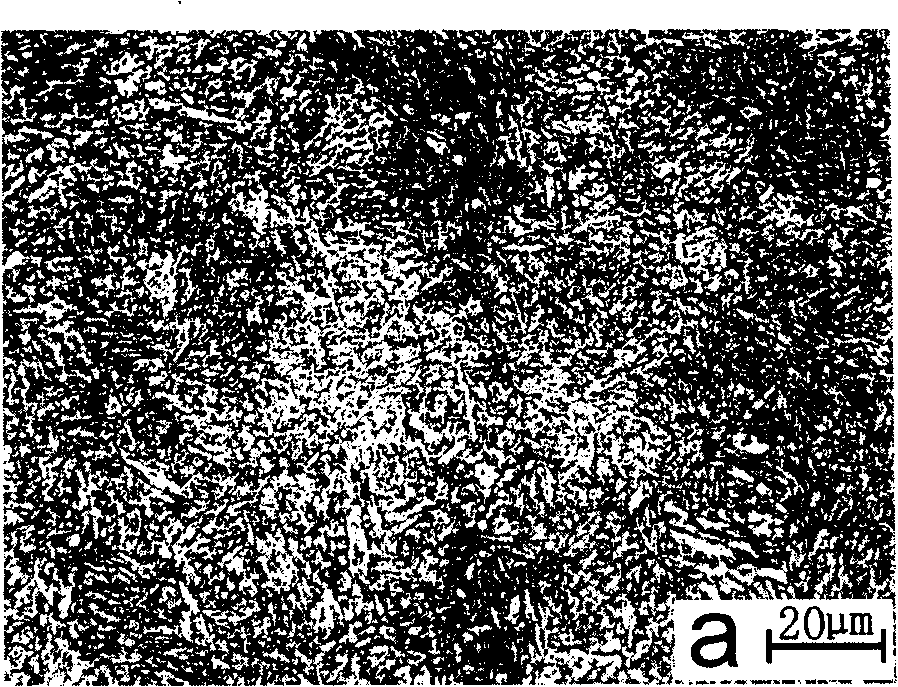

[0048] The microstructure treatment of the refinement module is air-cooled to room temperature at a solid solution temperature of 1090°C, and then undergoes two high-temperature tempering treatments at 860°C and 720°C. The process curve of the microstructure treatment is shown in figure 2 , the photo of the metallographic structure of the module after the microstructur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com