Two-frequency wideband electromagnetic band gap structure and making method

An electromagnetic bandgap structure, broadband technology, applied in the direction of radiation element structure, circuits, electrical components, etc., to shorten the patch geometry, reduce mutual coupling, and suppress surface waves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The substantive features and remarkable progress of the present invention are further clarified through the following specific embodiments.

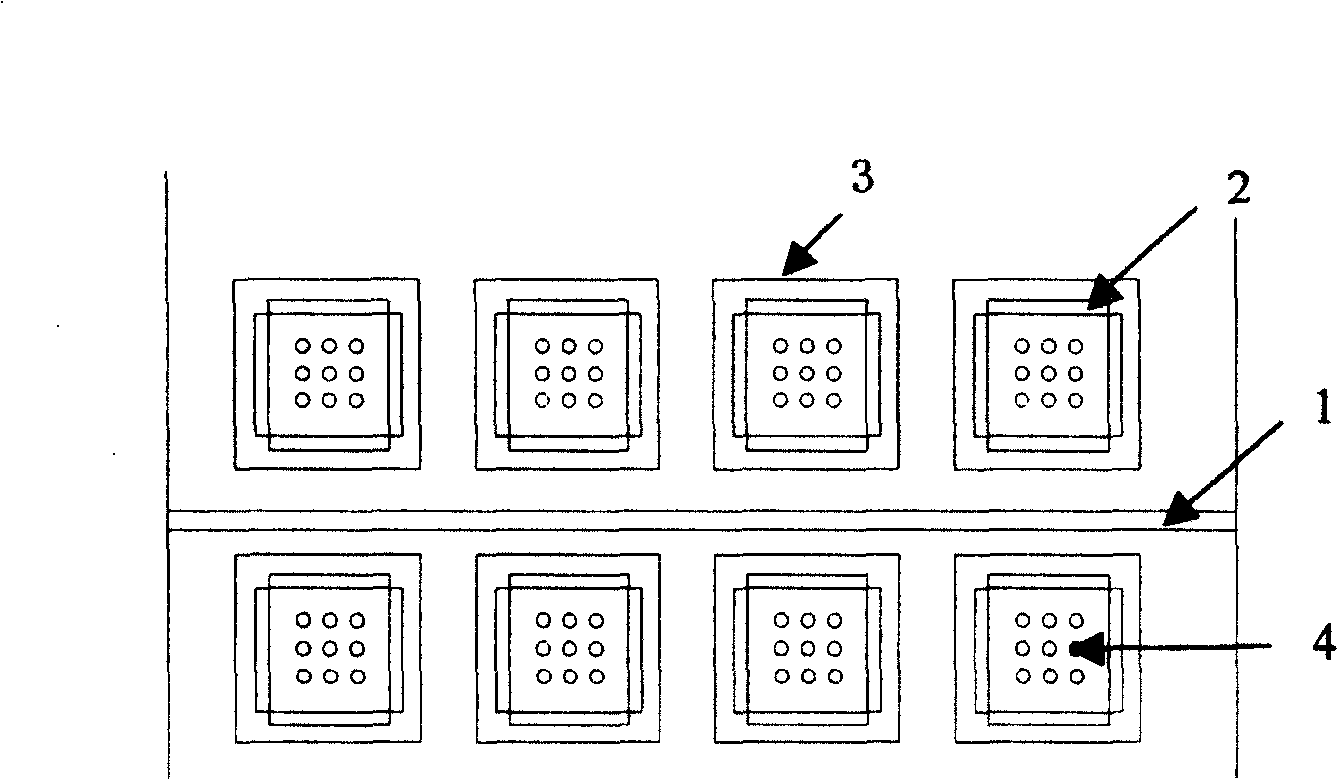

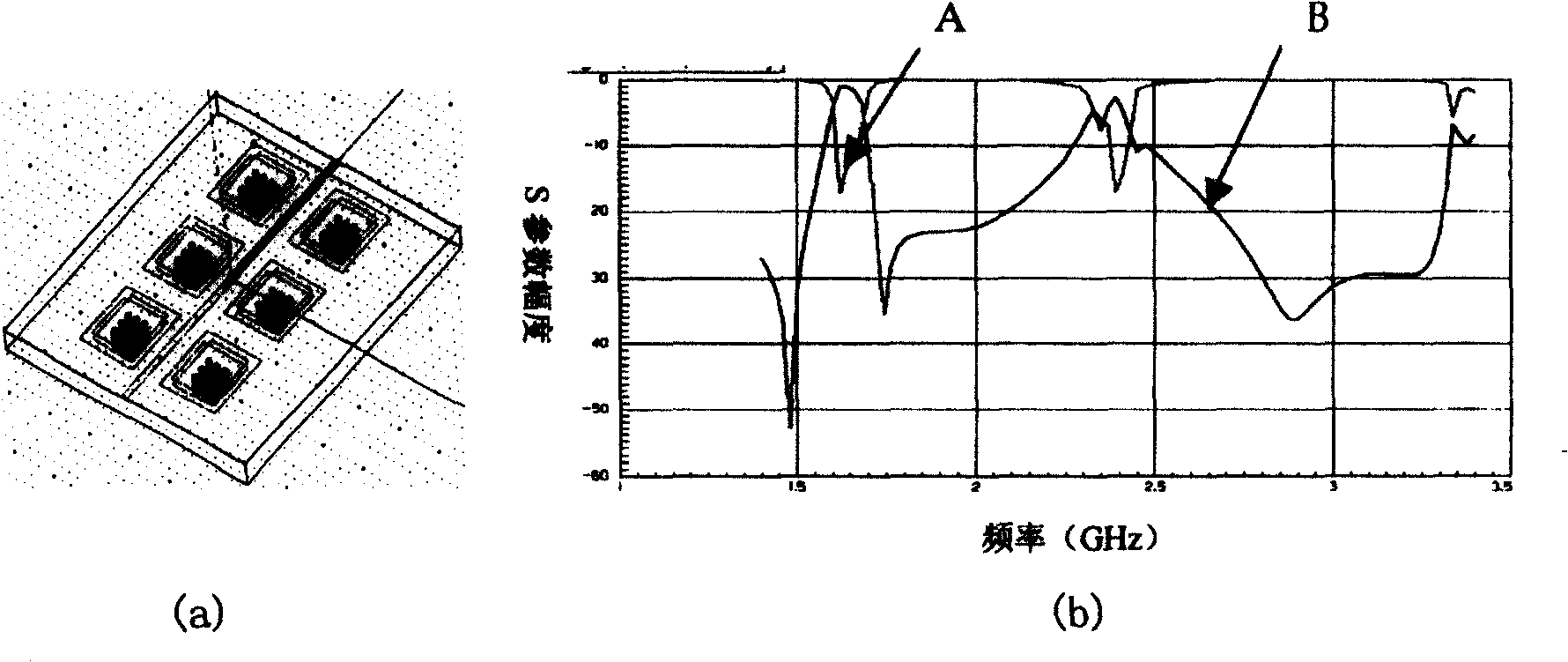

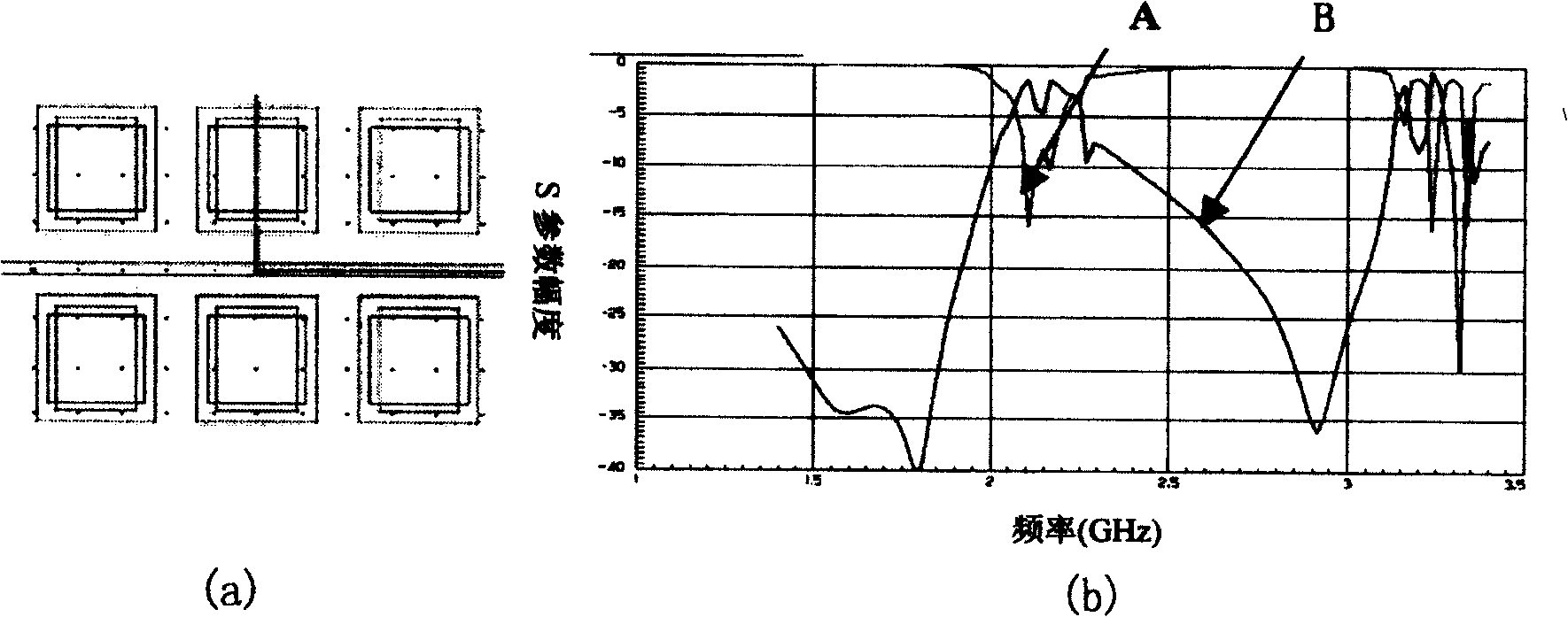

[0033] In order to shorten the size of the structural unit, the ε r =20 high dielectric constant (referred to as high K material) microwave dielectric material as the substrate, designed a dual-frequency broadband perforated high-resistance surface structure (see attached figure 1 ). Depend on figure 1 It can be seen that the dielectric substrate is rectangular (80mm×60mm×3mm); the surface of the dielectric is closely attached to a high-resistance surface electromagnetic bandgap (EBG) structure, which consists of three parts: a periodic metal patch unit (square, size 13.8mm×13.8mm), perforated narrow gaps on the patch unit (a total of 4 on each patch, with a size of 9mm×1mm) and metal cylinders with a distance of 2mm on the patch unit (a total of 4 on each patch) 9, the height is 3mm, the diameter is Φ=1mm), etc.; there is a 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com