Method for analyzing BEOL testing chip on-line failure

A failure analysis and chip technology, applied in electronic circuit testing, single semiconductor device testing, semiconductor/solid-state device testing/measurement, etc., can solve the problems of time-consuming and labor-intensive success rate, inability to optimize, low success rate, etc., to improve analysis efficiency and success rate, improve efficiency and accuracy, avoid the effect of destructive analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

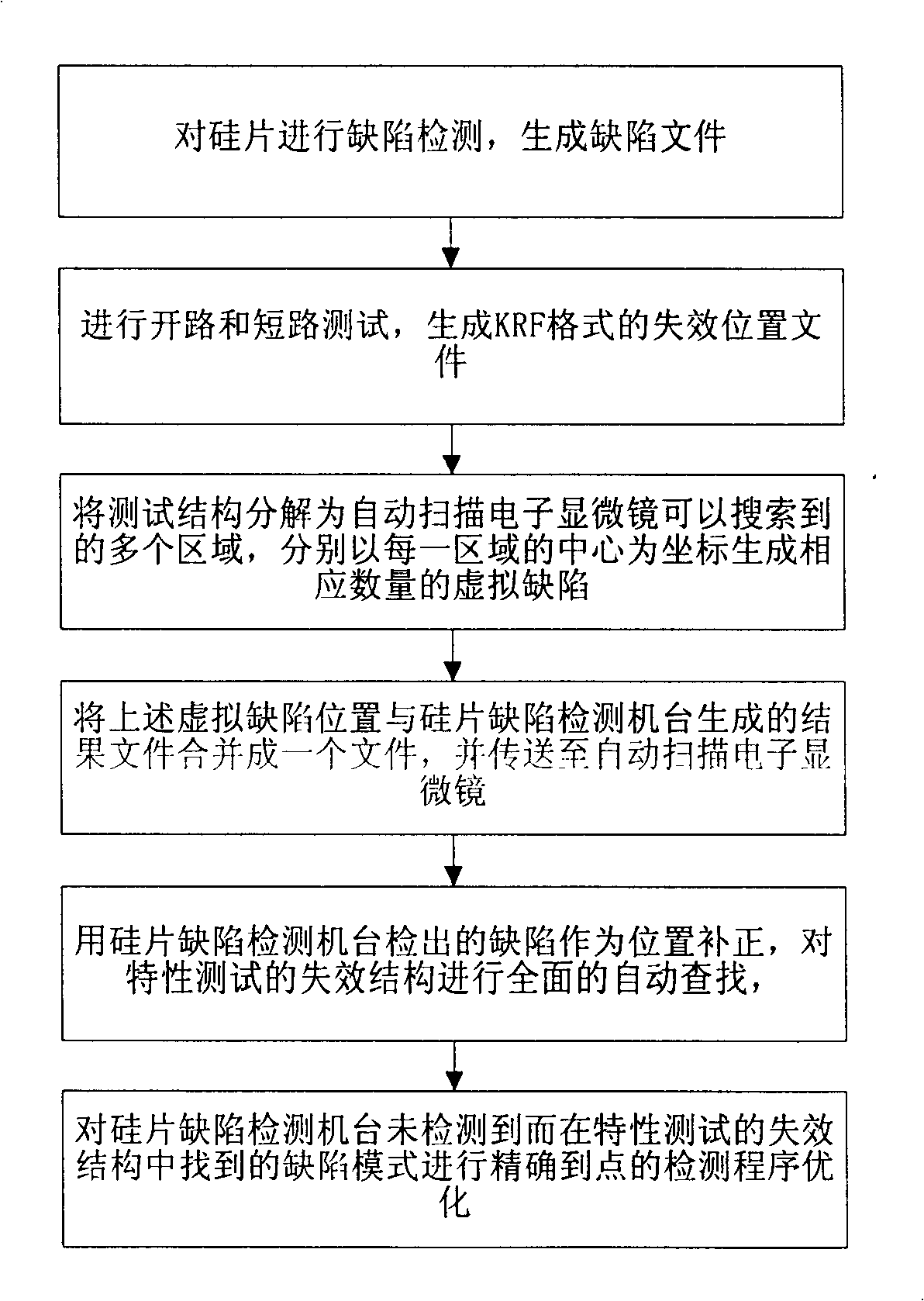

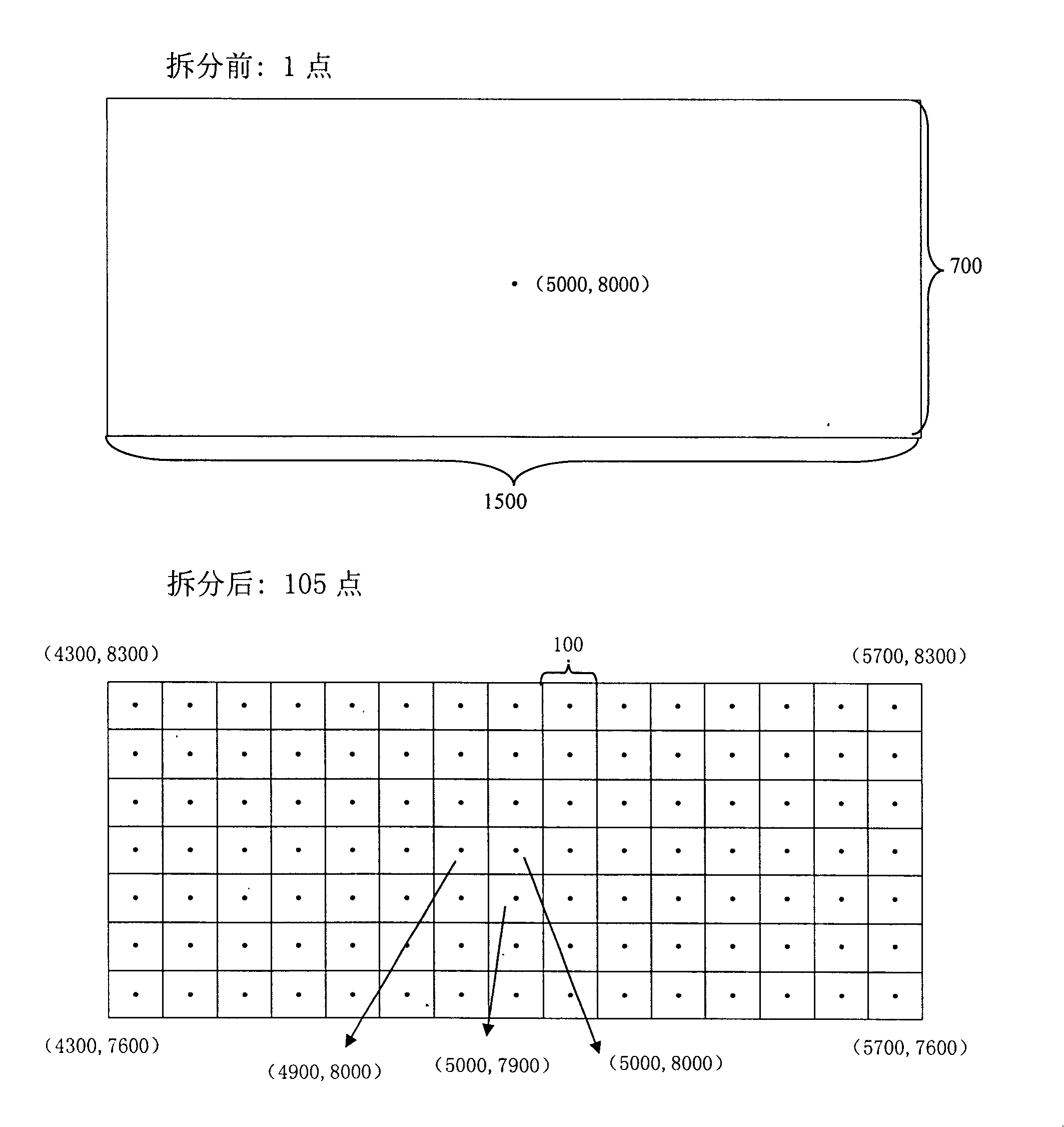

[0011] figure 1 It is a schematic flow chart of the present invention. Such as figure 1 As shown, firstly, the silicon wafer defect inspection machine is used for any layer of metal line engineering to detect the defects of the silicon wafer, and classify the detected defects, and select 5-10 point scanning electron microscopes at different positions of the silicon wafer Download the defects that are easy to find and whose size is less than 5 microns, and generate the KRF format result file ins.krf; then use the characteristic tester to perform open circuit and short circuit tests on the silicon chip, and also generate the KRF format failure location file pcm.krf, in In the above process, it is necessary to ensure that the origin of the silicon wafer and the origin of the chip of ins.krf and pcm.krf are consistent; figure 2 Schematic representation of multiple virtual defects generated for a failure structure for split feature testing. Such as figure 2 As shown, each fai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com