Micro light-filter piece built in mercury-cadmium-telluride infrared focal plane detector chip

A technology of infrared focal plane and detector chip, which is applied in the field of optical filters, can solve the problems of uniformity, reliability and transmittance of impossible optical filters, and achieve the effect of convenient use and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

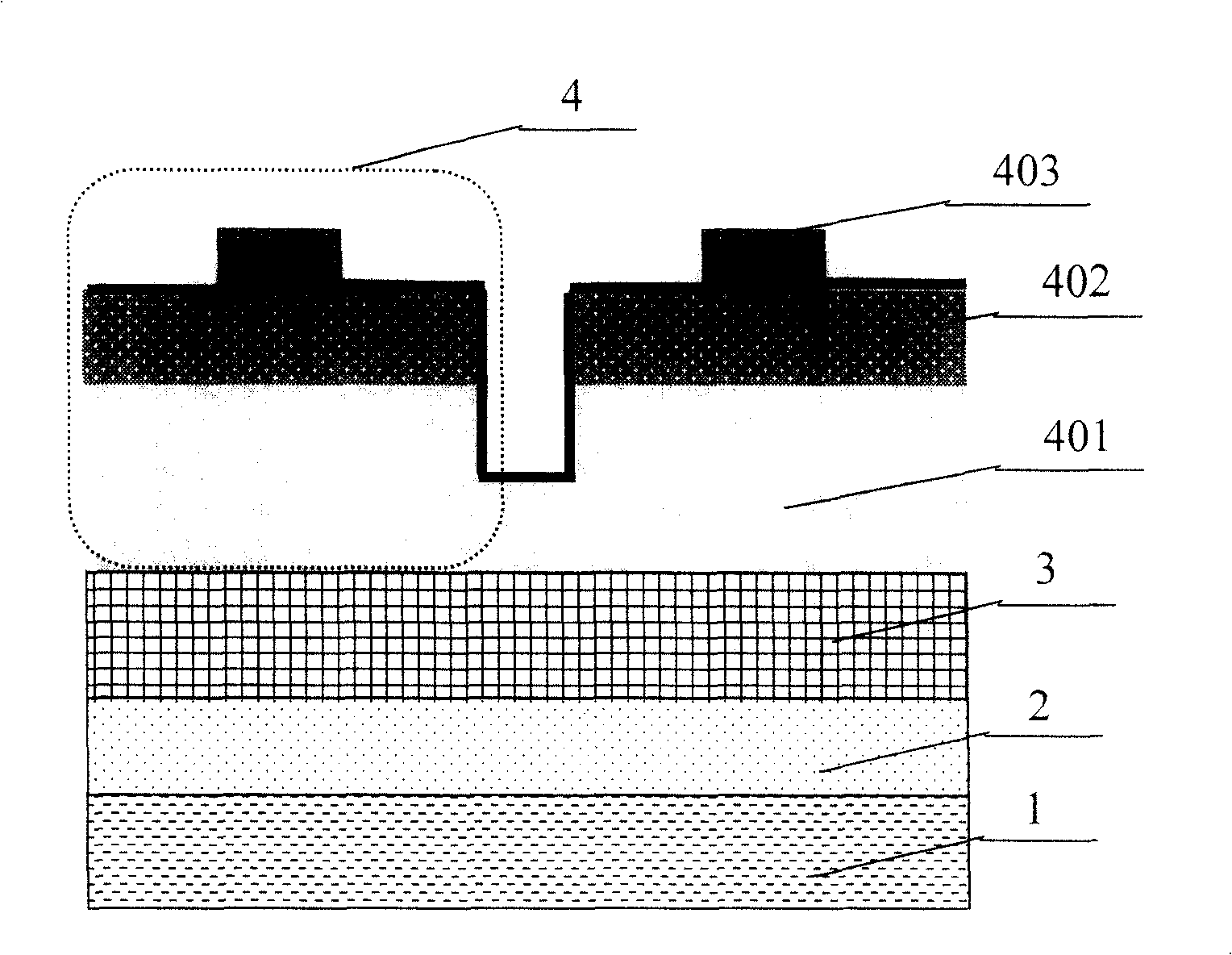

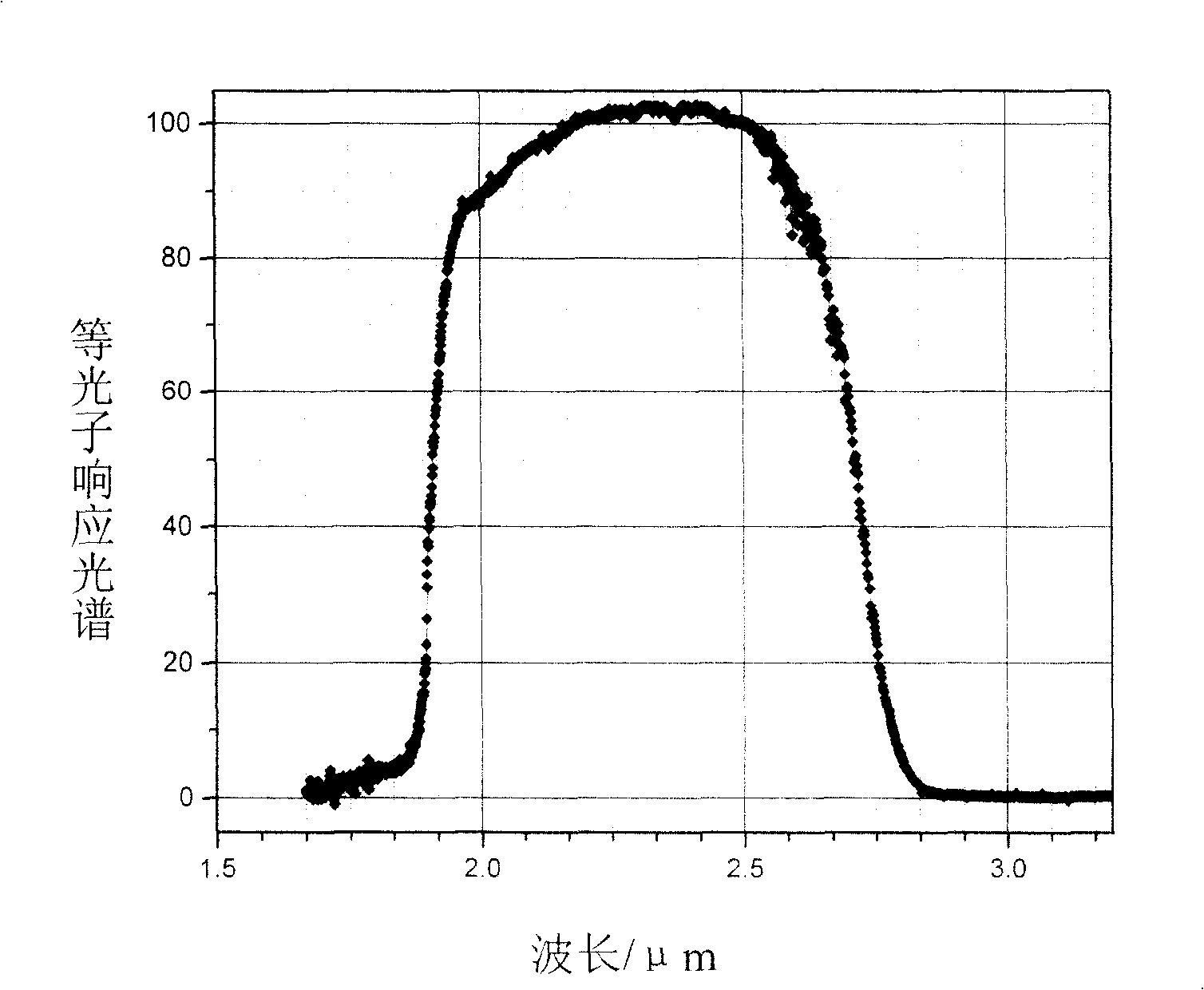

[0017] Below in conjunction with accompanying drawing, take the infrared focal plane detector that built-in short-wave cut-off wavelength is 1.95 μ m micro-filter as embodiment, the specific embodiment of the present invention is described in further detail:

[0018] The embodiment adopts P-on-n heterogeneous mesa junction HgCdTe infrared focal plane detector, the cut-off wavelength of the micro-filter is 1.95 μm, and its preparation process is as follows:

[0019] A. Firstly, a CdTe buffer layer 2 is sequentially grown on the GaAs substrate 1 by molecular beam epitaxy technology, with a thickness of 4 μm;

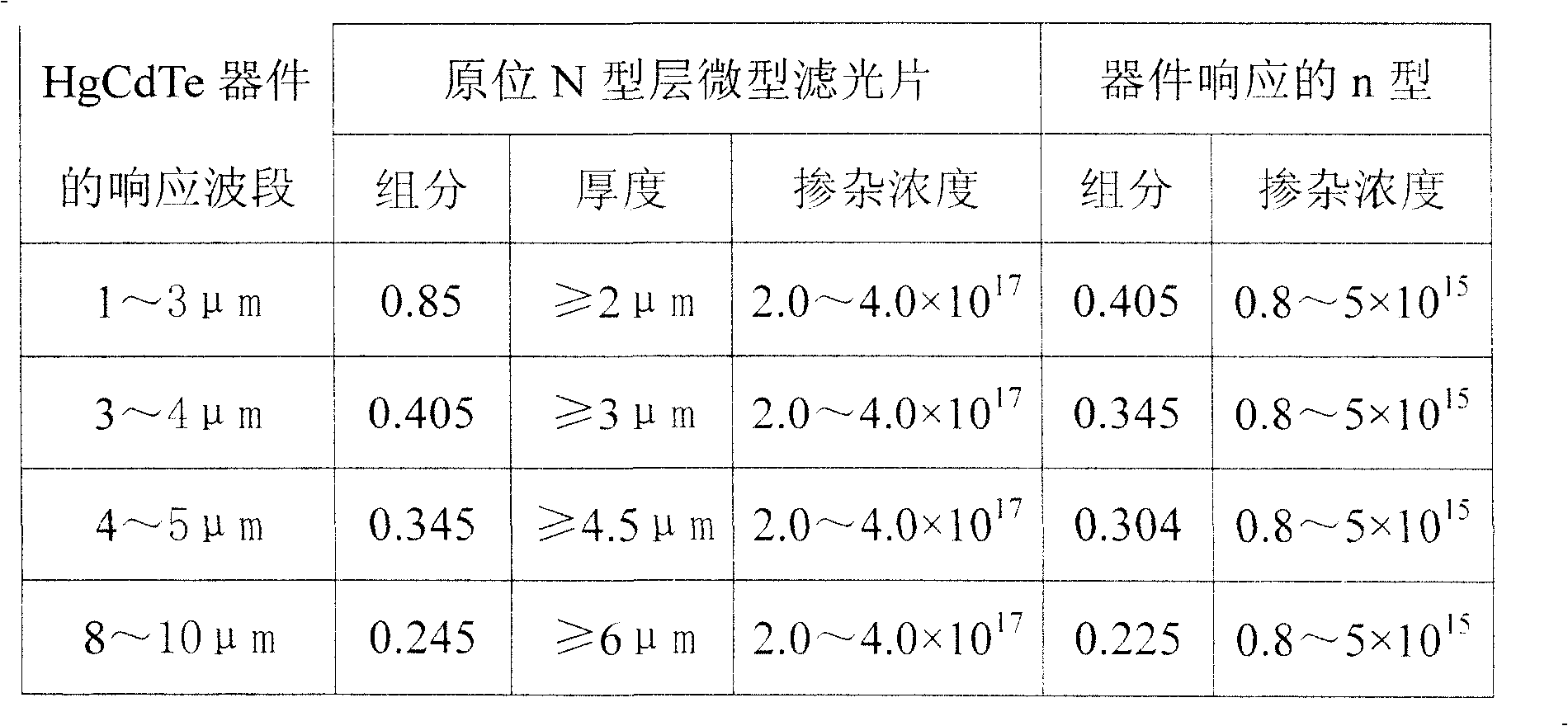

[0020] B. Re-growth indium doping concentration is 3.0×10 17 , N-type Hg with a thickness of 5 μm and a composition of 0.545 1-0.545 Cd 0.545 Te material is used as a micro filter 3 with a cutoff wavelength of 1.95 μm. The reciprocal of the absorption coefficient of the micro-filter HgCdTe material is only 1 μm, much smaller than 5 μm. Therefore, when the incident wave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com