Vitamic C controlled release pill and its preparation method and use

A technology for sustained-release pellets and vitamins, which is applied in pharmaceutical formulations, medical preparations containing active ingredients, drug delivery, etc. It can solve the problems that no sustained-release preparations have been developed, and achieve improved bioavailability, good stability, and improved compliance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

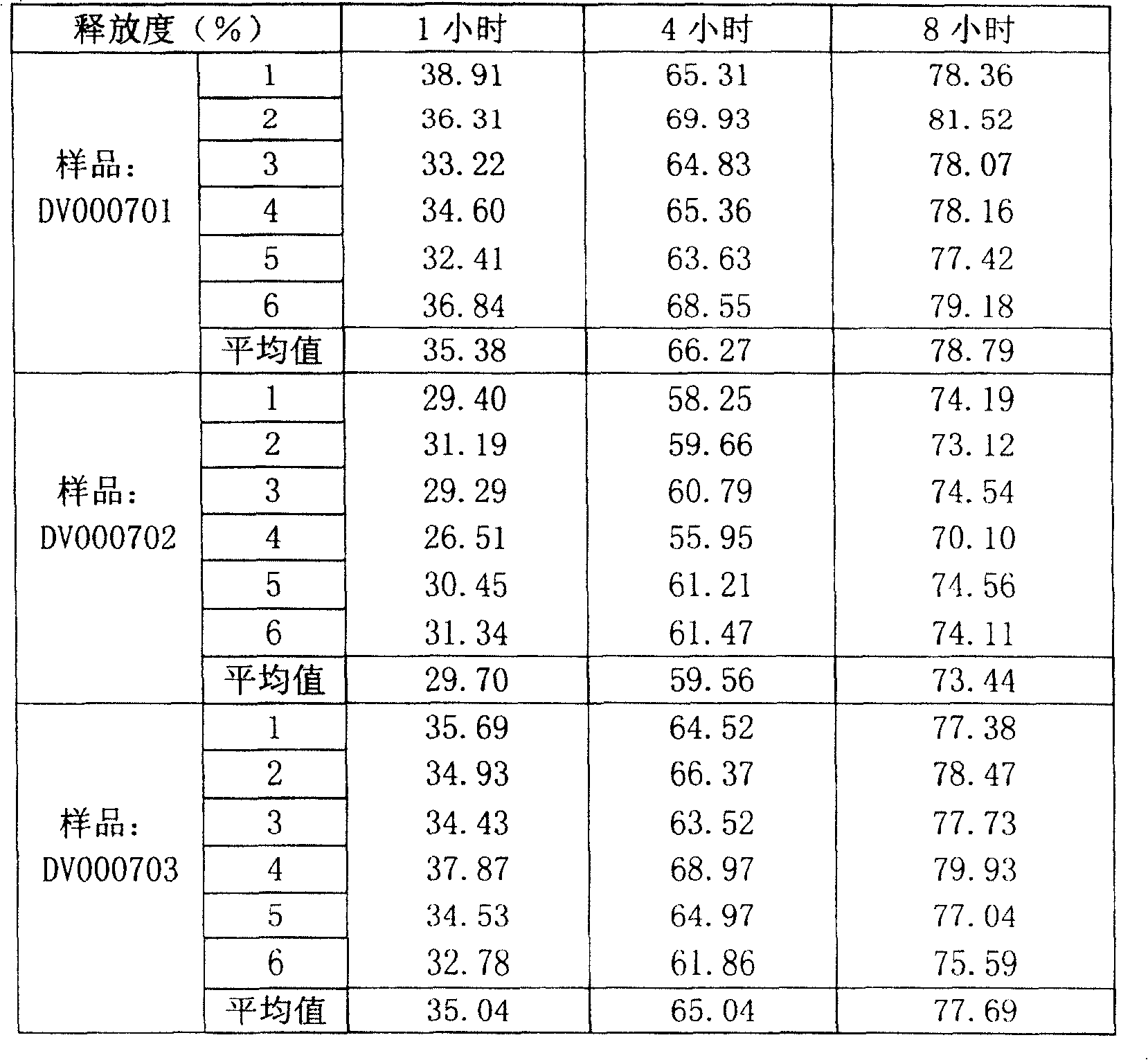

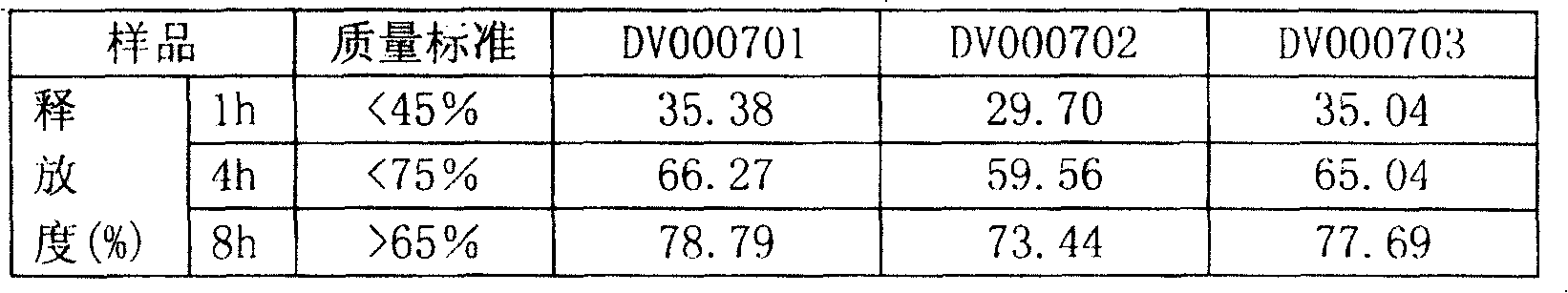

Examples

Embodiment 1

[0039] Embodiment 1, the preparation of sustained-release pellets (containing 510 grams of vitamin C)

[0040] 1.1 Raw materials and accessories

[0041] Microcrystalline cellulose is selected as blank core, citric acid is used as metal chelating agent, acrylic resin is used as coating auxiliary material, and talcum powder is used as lubricant.

[0042] 1.2 Preparation process

[0043] 1) Load the main drug: put the blank core (microcrystalline cellulose) in the coating pan, adjust the temperature of the coating pan to 55°C, and the speed to 40 rpm, spray a 20% acrylic resin solution containing citric acid, and gradually Spray the main ingredient vitamin C until 500 grams of the main ingredient is added;

[0044] 2) Coating: prepare 40% acrylic resin solution with ethanol, put the small particles in the coating pot, adjust the temperature of the coating pot to 55° C. and the rotating speed to 40 rpm, spray the acrylic resin solution, and gradually spray talcum powder in an a...

Embodiment 2

[0048]Embodiment two, the preparation of sustained-release pellets (containing 650 grams of vitamin C)

[0049] Corn starch particles are selected as the blank core, dimercaptoethylglycine is used as the metal chelating agent, shellac is used as the coating auxiliary material, and silicon dioxide is used as the lubricant.

[0050] Referring to the process steps described in Example 1, each component was added in sequence to prepare sustained-release pellets containing 650 grams of vitamin C. During the preparation process, the temperature of the coating pan was controlled at 70° C., and the rotation speed was 60 rpm.

[0051] The prepared slow-release pellets per kilogram approximately contain: 650 grams of vitamin C, 150 grams of blank core (corn starch), 10 grams of dimercaptoethylglycine, 110 grams of shellac, 80 grams of talcum powder, and an appropriate amount of 95% ethanol .

Embodiment 3

[0052] Embodiment three, the preparation of sustained-release pellets (containing 800 grams of vitamin C)

[0053] Sucrose particles were selected as the blank core, tartaric acid was used as the metal chelating agent, povidone was used as the coating auxiliary material, and silicon dioxide was used as the lubricant.

[0054] Referring to the process steps described in Example 1, each component was added in sequence to prepare sustained-release pellets containing 800 grams of vitamin C. During the preparation process, the temperature of the coating pan was controlled at 89° C., and the rotation speed was 35 rpm.

[0055] The prepared slow-release pellets per kilogram approximately contain: 800 grams of vitamin C, 80 grams of blank core (sucrose particles), 5 grams of tartaric acid, 70 grams of povidone, 45 grams of silicon dioxide, and an appropriate amount of 95% ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com