Organic semiconductor compound and its preparation method and uses

A technology of organic semiconductors and organic photoconductors, applied in the preparation of organic compounds, semiconductor/solid-state device manufacturing, organic chemistry, etc., can solve the problems of deteriorating working environment and easy oxidation of devices, and achieve wide application prospects and excellent photoconductive properties , Facilitate the effect of mass synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

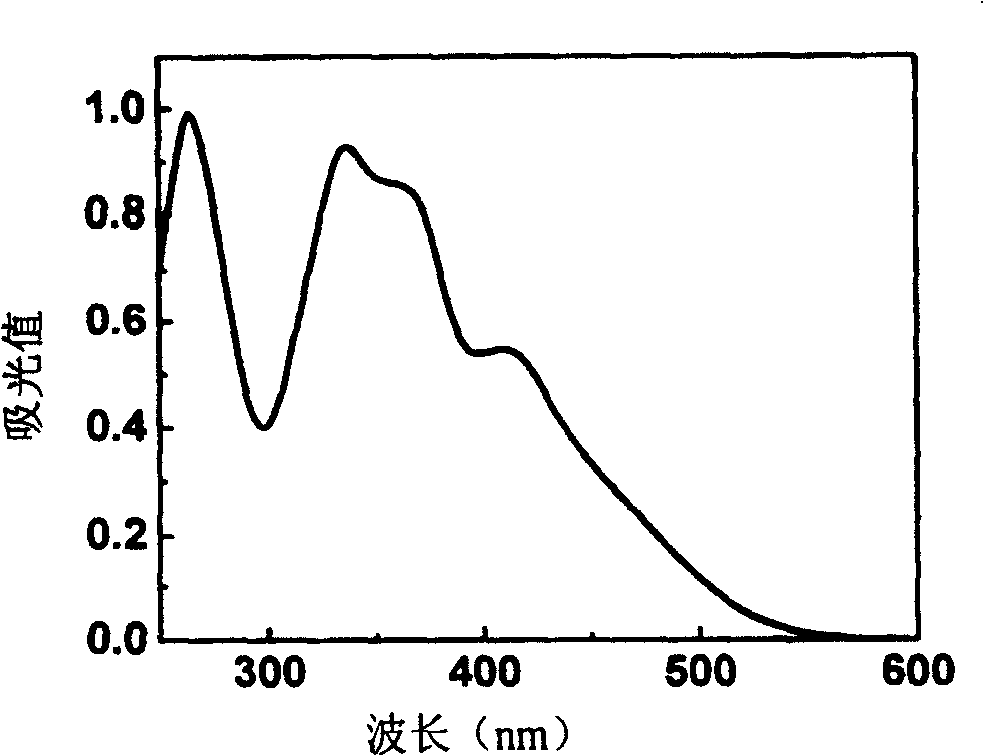

[0037] Example 1, using titanium tetrachloride and N-methylmorpholine as a catalyst to synthesize 2,2',2"-(5H-tribenzo[a,f,k]triindene-5,10,15-triethylene base) tris(2-cyanoacetate methyl ester) (compound VIII, C 39 h 21 N 3 o 6 )

[0038] Take 0.77g (2mmol) of irindone and 1.8ml (20mmol) of methyl cyanoacetate, and add 50ml of dichloromethane as a reaction solvent. The mixture was predispersed using ultrasound for 30 min, and then 1.3 ml of titanium tetrachloride (12 mmol) and 4.0 ml of N-methylmorpholine (36 mmol) were sequentially added dropwise under stirring. The reaction system was sealed, placed in an ultrasonic water bath, and reacted at 25° C. for 5 h. 120ml of water was added to the reaction system, and then 150ml of dichloromethane was added for extraction. The organic phase was taken and the solvent was evaporated to dryness to obtain a dark red solid. The solid was washed successively with ethyl acetate and methanol, and finally recrystallized in a mixed so...

Embodiment 2

[0042] Embodiment 2, using titanium tetrachloride and pyridine as a catalyst to synthesize compound 2,2',2 "-(5H-tribenzo[a,f,k]triindene-5,10,15-triylidene) three ( 2-Ethyl cyanoacetate) (Compound IX, C 42 h 27 N 3 o 6 )

[0043] Take 0.77g (2mmol) of irindone and 1.8ml (20mmol) of methyl cyanoacetate, and add 50ml of dichloromethane as a reaction solvent. The mixture was predispersed using ultrasound for 30 min, and then 1.3 ml of titanium tetrachloride (12 mmol) and 2.9 ml of pyridine (36 mmol) were sequentially added dropwise with stirring. The reaction system was sealed, placed in an ultrasonic water bath, and reacted at 25° C. for 5 h. 120ml of water was added to the reaction system, and then 150ml of dichloromethane was added for extraction. The organic phase was taken and the solvent was evaporated to dryness to obtain a dark red solid. The solid was washed successively with ethyl acetate and methanol, and finally recrystallized in a mixed solvent of ethanol and...

Embodiment 3

[0047] Embodiment 3, use titanium tetrachloride and N-methylmorpholine as catalyst synthesis compound IX

[0048] Take 0.77g (2mmol) of irindone and 2.1ml (20mmol) of ethyl cyanoacetate, and add 50ml of dichloromethane as a reaction solvent. The mixture was pre-dispersed by ultrasound for 30 min, and then 1.3 ml of titanium tetrachloride (12 mmol) and 4.4 ml of N-methylmorpholine (40 mmol) were sequentially added dropwise under stirring as a catalyst. The reaction system was sealed, placed in an ultrasonic water bath, and reacted at 25° C. for 5 h. 120ml of water was added to the reaction system, and then 150ml of dichloromethane was added for extraction. The organic phase was taken and concentrated, and the concentrated solution was passed through a 200-300 mesh silica gel column with dichloromethane as the eluent to collect the red component therein. Finally, it was recrystallized in a mixed solvent of ethanol and dichloromethane to obtain 0.68 g of red flaky crystals (51%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com