Method for preparing polycrystal diamond particle allocated with wide particle size

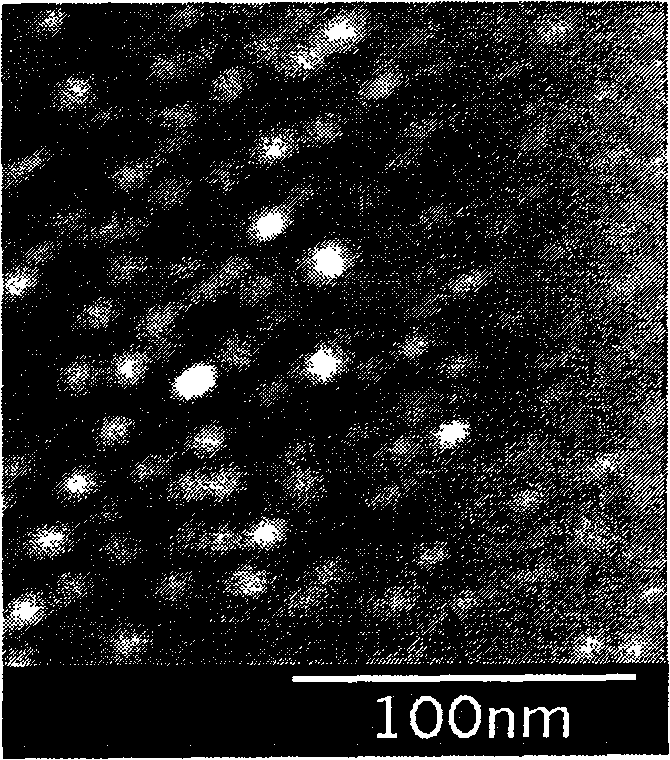

A technology of polycrystalline diamond and polycrystalline diamond, which is applied in the field of preparation of polycrystalline diamond particles, can solve problems such as environmental vibration and noise pollution, complex molding and filling of raw materials, and difficult product recovery, and achieves small environmental impact, unique cutting function, The effect of wide particle distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with embodiment.

[0036] (1) Ingredients

[0037] According to TNT:RDX:HMX=1:8:1-7:2:1, C:(RDX+TNT+HMX)=1:7-1:9.5 weight ratio batching. The charge is carried out in the form of injection and press-fitting.

[0038] The present embodiment batching consumption:

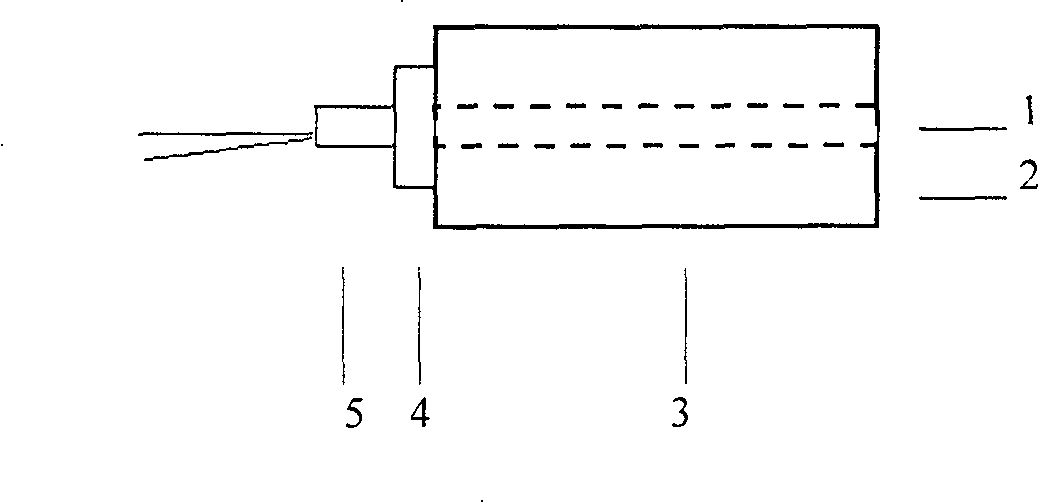

[0039] Using the Mach effect to increase the synthesis pressure is to wrap a layer of high-detonation velocity explosives RDX and HMX outside the TNT and external carbon source mixed grain, so that Mach reflection will be generated in the inner core grain during the detonation process of the explosive, thereby improving the synthetic efficiency. Pressure, part of HMX can also be replaced by PETN to increase detonation stability.

[0040] When filling, use copper or aluminum temperature-controlled water bath pot as the chemical material. The temperature of the water bath is controlled at 85-98°C. After it is completely melted, pour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com