Method and device for producing poriferous and loose dry product of traditional Chinese medicine extract

A production method and technology of vacuum drying equipment, which are applied in the directions of drying solid materials, pharmaceutical formulations, drying gas layout, etc., can solve the problems of poor appearance quality of dried products, high energy consumption, low automation level, etc. The effect of good solubility and reasonable equipment design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

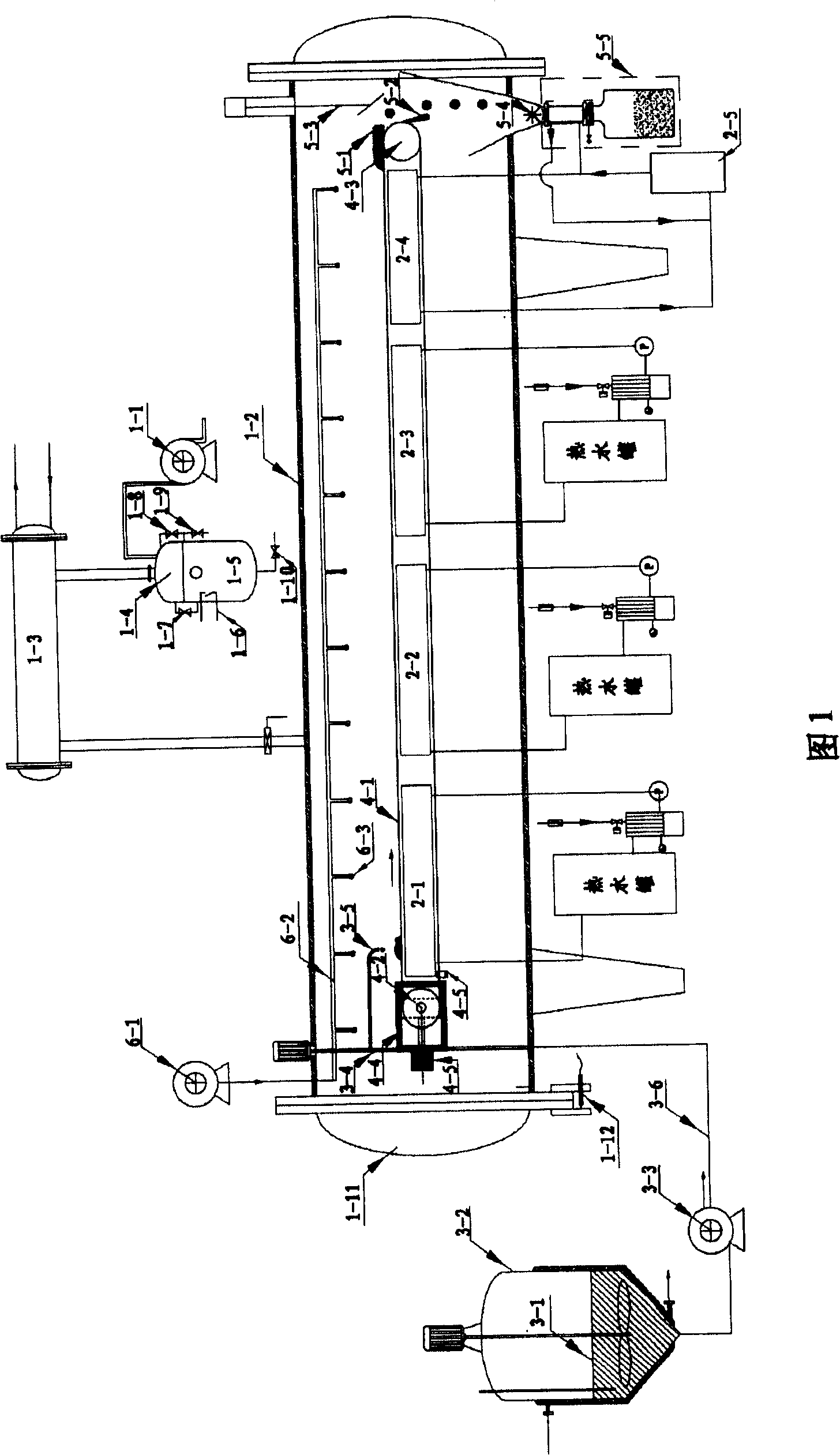

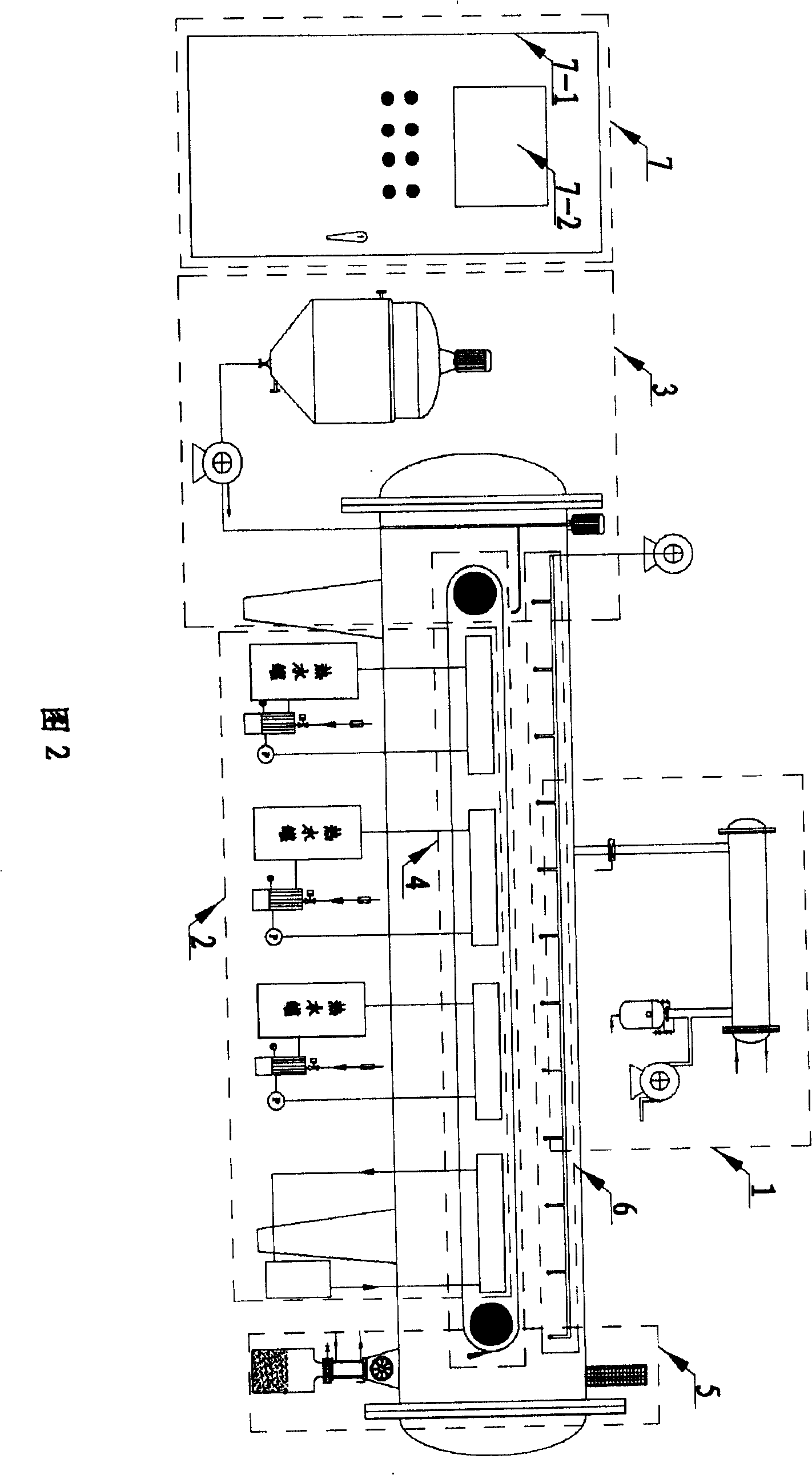

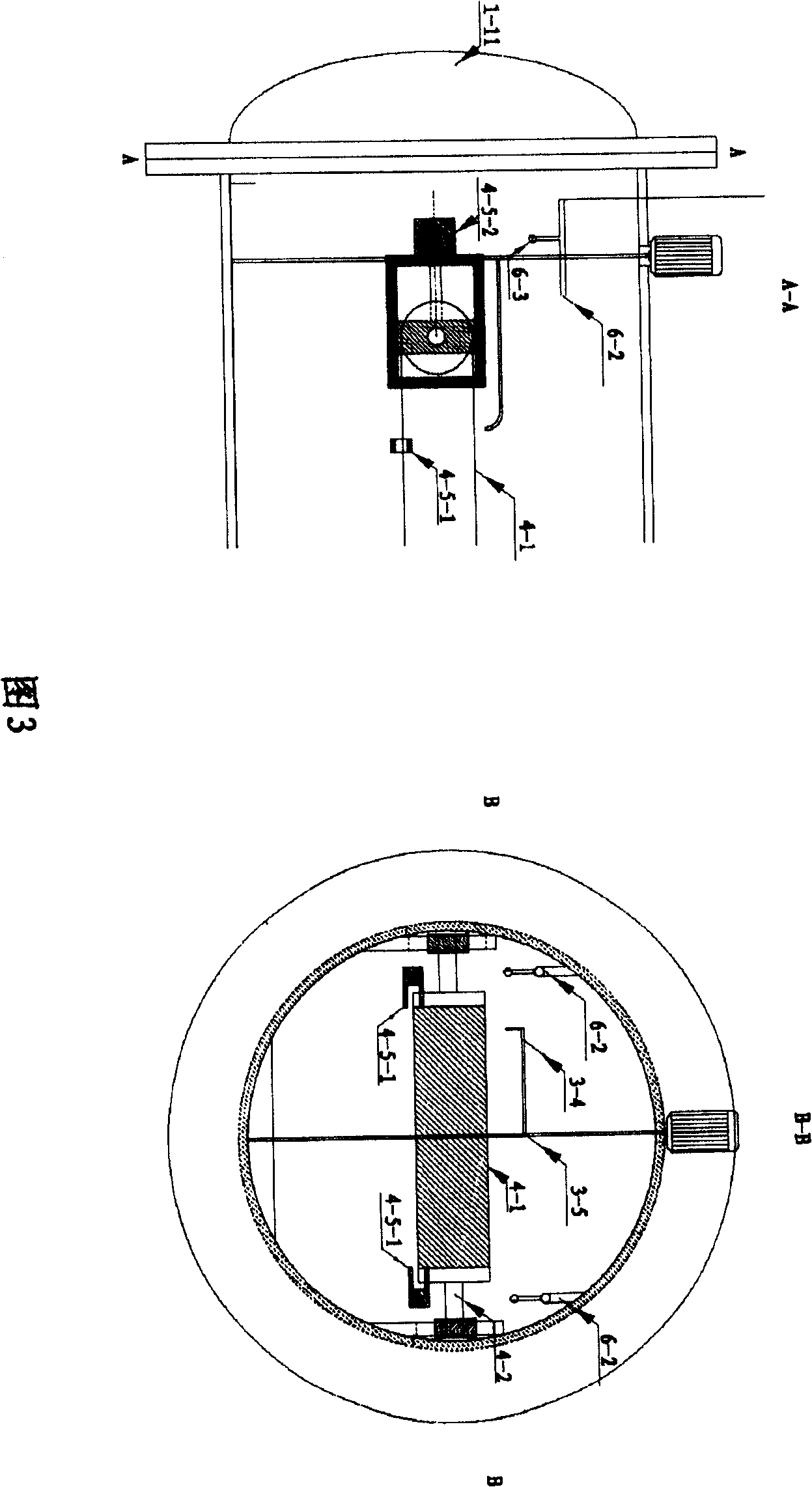

[0023] Referring to Fig. 1~4, the full-automatic low-temperature continuous vacuum drying equipment of the present invention comprises vacuum system (1), heating, cooling system (2), feeding material distribution system (3), material delivery system (4), unloading system ( 5), automatic cleaning system (6) and automatic control system (7). The vacuum system (1) has a Roots water ring vacuum unit (1-1) and a condenser (1-3) connected to the vacuum cavity (1-2). The vacuum cavity has an insulating layer, and the vacuum unit ( 1-1) and the condenser (1-3) are connected with a vacuum buffer tank (1-4) and a condensate collection tank (1-5), and the water vapor or organic solvent vapor in the drying process passes through the condenser (1- 3) After condensation, enter the condensate collection tank (1-5). The heating and cooling system (2) has three heating zones (2-1, 2-2, 2-3) and one cooling zone (2-4). The temperature of the hot water medium in the heating zone can be adjusted...

Embodiment 2

[0030] Referring to Fig. 1-4, the production method of the porous and loose traditional Chinese medicine extract dry matter of the present invention is to apply the extract material (3-1) evenly on the conveyor belt (4-1) under vacuum conditions, and carry out Low temperature continuous drying. The extract material (3-1) is preheated in the feed tank (3-2), and the feed temperature is controlled at 30-60°C. When the vacuum chamber (1-2) reaches the set vacuum degree (generally 400pa), the extract material is evenly coated on the conveyor belt (4-1) by the screw feed pump (3-3) at a feed rate of 1 to 10kg / h through the distributor (3-4) , the conveyor belt runs at a speed of 3-24m / h, moves through each heating zone (2-1, 2-2, 2-3) in turn, and finally passes through the cooling zone (2-4). In a vacuum environment, the extract material evaporates rapidly after absorbing heat, and water vapor or organic solvent vapor enters the condensate collection tank (1-5) after being conden...

Embodiment 3

[0032] Referring to Fig. 1-4, the production method and the equipment of the porous and loose traditional Chinese medicine extract dry matter of the present invention, the operating process is as follows: open the automatic control system (7) of the full-automatic low-temperature continuous vacuum drying equipment, complete the feeding tank temperature, heating Zone temperature, cooling zone temperature, condenser cooling medium temperature, feed speed, conveyor belt speed, fabric distribution angle and other process parameters setting, when the feed tank temperature, heating zone temperature, cooling zone temperature reach the set value, The vacuum system (1) starts to start, and when the vacuum degree of the vacuum chamber (1-2) reaches 400pa, start the feed distribution system (3) and the material conveying system (4), and evenly coat the extract material on the conveying On the belt (4-1), the extract material passes through three sections of heating zones (2-1, 2-2, 2-3) a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com