Sealant for liquid crystal and liquid-crystal display cell made with the same

A sealant, liquid crystal technology, applied in chemical instruments and methods, optics, instruments, etc., can solve the problems of poor liquid crystal orientation, reduce the reliability of display panels, and display irregularities, and achieve the effect of good reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

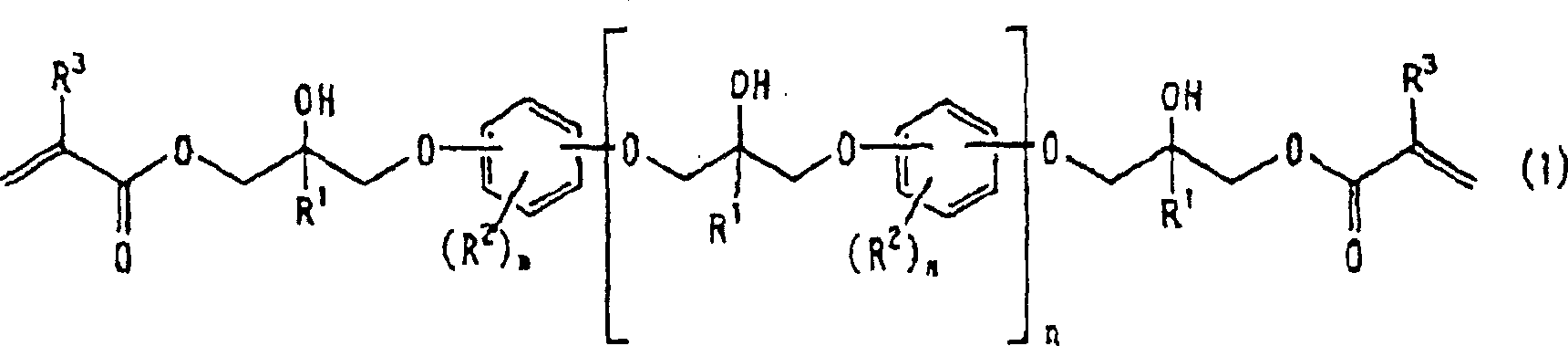

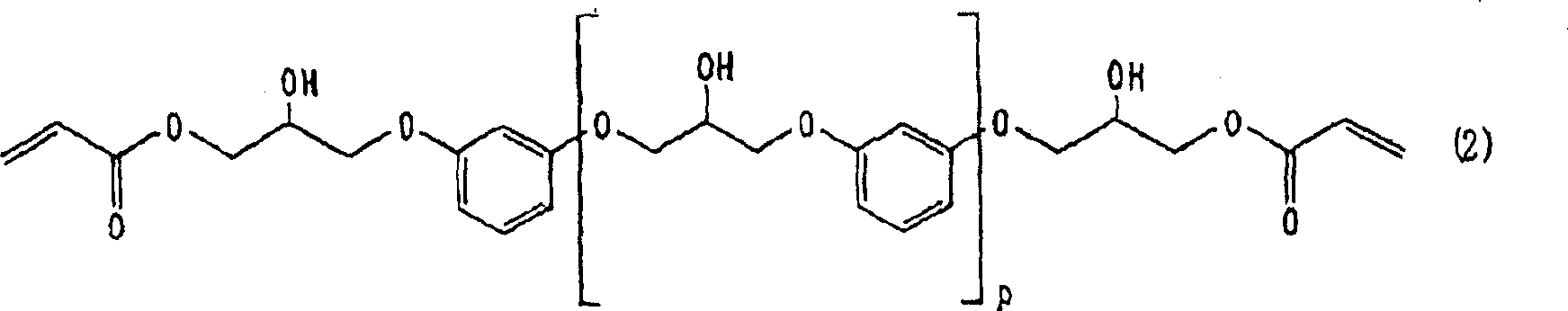

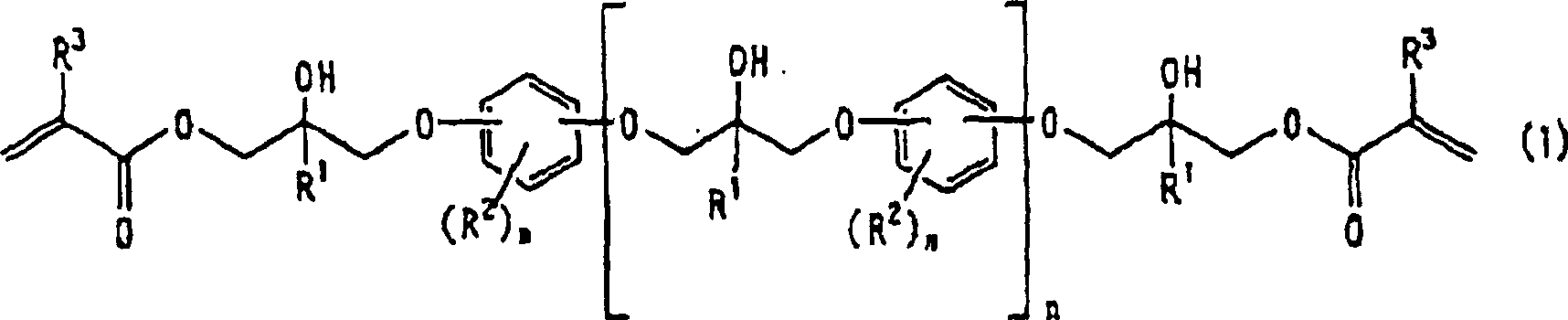

Method used

Image

Examples

Embodiment 1

[0089] The epoxy acrylate A of 80 weight parts synthesis embodiment 1, the epoxy resin EBPS-300 of 20 weight parts (epoxy equivalent: 233g / eq, bisphenol S type epoxy resin, Nippon Kayaku Co., Ltd.'s product), 1.8 parts by weight of radical photopolymerization initiator 3,6-bis(2-methyl-2-morpholinopropionyl)-9-n-octylcarbazole (AdekaOptomerN-1414; product of Asahi Denka Kogyo) , 1.2 parts by weight of aminosilane coupling agent (KBM-603, N-β (aminoethyl) γ-aminopropyltrimethoxysilane, the product of Shin-etsu Silicone) was heated and dissolved at 90°C to obtain a resin solution . The mixture was cooled to room temperature, then added 5 parts by weight of isophthalic dihydrazide (trade name IDH-S; the jet milled pulverized grade material provided by Otsuka Chemistry Inc., and further finely pulverized with a jet mill; melting point 224 ° C, active Hydrogen equivalent 48.5 g / eq; average particle diameter 1.7 micrometers; maximum particle diameter 7 micrometers), 30 parts by wei...

Embodiment 2

[0091] 80 parts by weight of epoxy acrylate A, 20 parts by weight of epoxy resin EBPS-300 (epoxy equivalent: 233g / eq, bisphenol S type epoxy resin, Nippon Kayaku Co., Ltd. product), 1.8 parts by weight of radical photopolymerization initiator 3,6-bis(2-methyl-2-morpholinopropionyl)-9-n-octylcarbazole (AdekaOptomerN-1414; product of Asahi Denka Kogyo) 1.2 parts by weight of an aminosilane coupling agent (KBM-603, N-β(aminoethyl)γ-aminopropyltrimethoxysilane, a product of Shin-etsu Silicone) was heated and dissolved at 90°C to prepare a resin solution. The mixture was cooled to room temperature, and then 6.5 parts by weight of Amicure-VDH (1,3-bis(hydrazinocarboethyl)-5-isopropylhydantoin, a product finely pulverized by a jet mill from Ajinomoto Fine Techno was added ), 30 parts by weight of alumina (SPC Aluminum, a product of C.I.Kasei, Inc., with an average particle diameter of 1.0 μm), and 7 parts by weight of core-shell rubber particles: Paraloid EXL-2655 (a product of Kureh...

experiment Embodiment 2

[0097] Next, liquid crystal contamination test (UV-irradiation and thermal curing), adhesive strength test and glass transition temperature test were carried out on the liquid crystal sealants prepared in Examples 1 and 2 and Comparative Examples 1 and 2.

[0098] Liquid crystal contamination test (UV-irradiation and thermal curing)

[0099] Next, the resistivity of the contact liquid crystal is tested as an index of the liquid crystal contamination property.

[0100] 0.1 g of a sealant for liquid crystal was put in a sample tube, and 1 mL of liquid crystal (MLC-6866-100; product of Merck) was added thereto. After irradiating the mixture with 2000 mJ / cm2 of ultraviolet light with a UV radiation instrument, the sample tube was placed in an oven and kept at 120° C. for 1 hour; after that, it was allowed to stand at room temperature for 0.5 hour. After these processes, only the liquid crystals were taken out from the treated sample tubes, and the components eluted into the liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com