Method for cleaning residual metal

A technology for residual metal and residue removal, which is applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

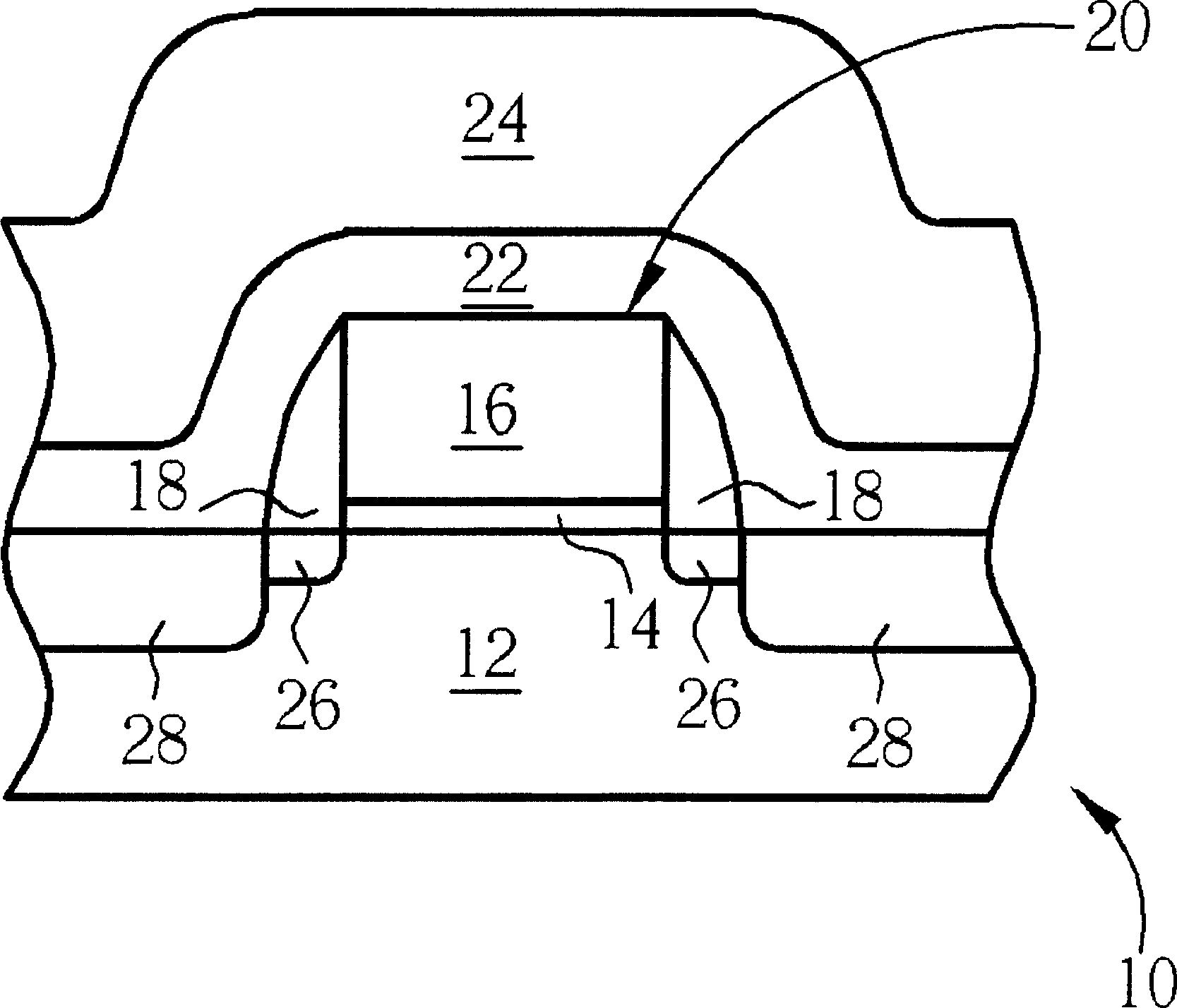

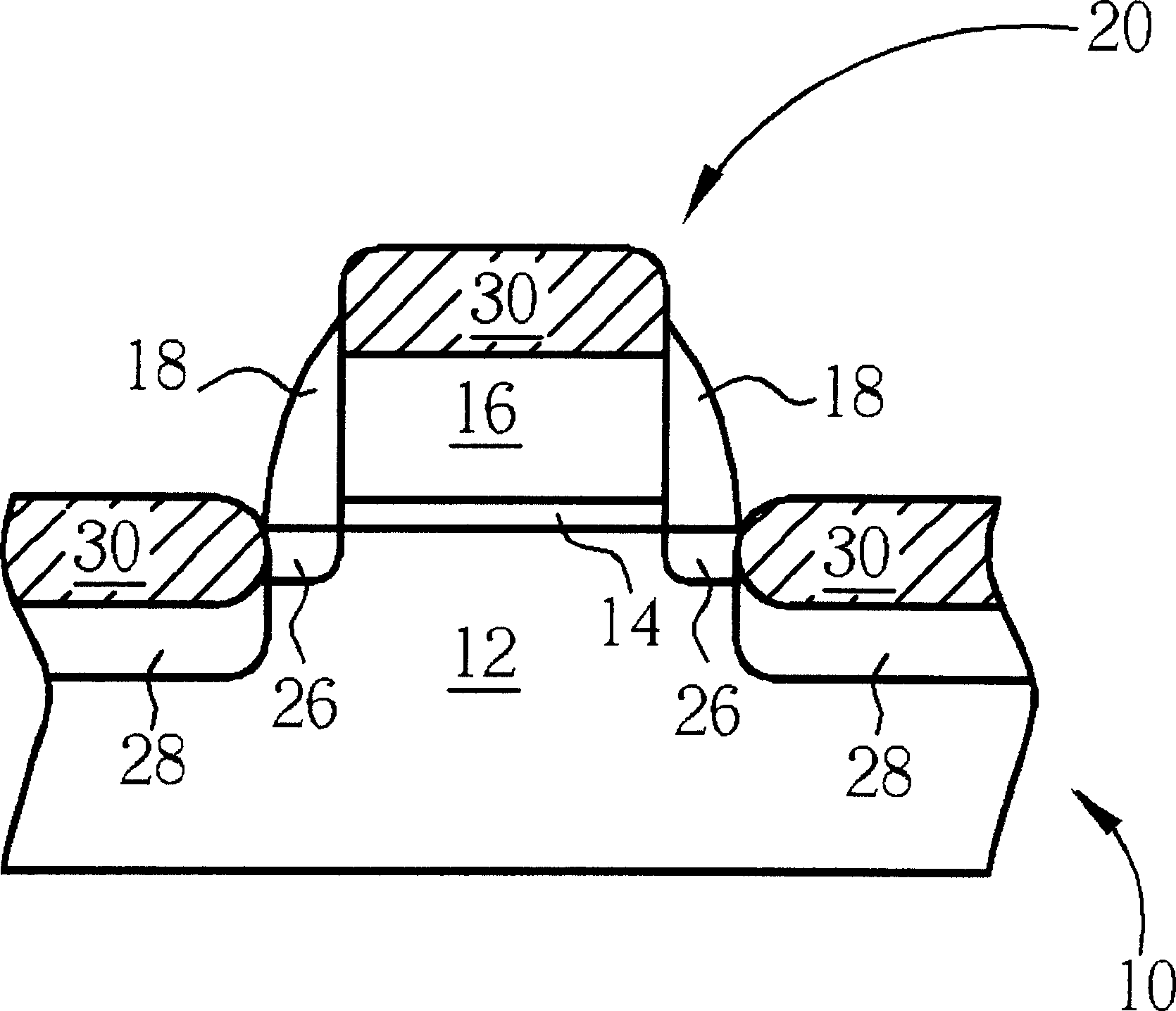

[0041] Please refer to Figures 5 to 6 , Figures 5 to 6 It is a schematic diagram of a method for removing residual metal on a transition metal silicide in a preferred embodiment of the present invention. Such as Figure 5 As shown, a semiconductor chip 50 has a substrate 52 thereon, which in the preferred embodiment is a silicon substrate. A gate structure 60 is formed above the substrate 52, wherein the gate structure 60 includes a gate insulating layer 54 and a gate conductive layer 56, and the gate insulating layer 54 may be made of a nitrogen oxide layer, a nitride layer, an oxide layer or other dielectric layers. electrical layer; and the gate conductive layer 56 may be formed of conductive structures such as doped polysilicon or metal layers.

[0042] After the gate structure 60 is formed, a source / drain extension region 66 is formed in the substrate 52 on both sides of the gate structure 60 by using an ion implantation process that can reduce the thermal budget, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com