Semiconductor device and manufacturing method thereof

A semiconductor and transistor technology, applied in the field of forming field electrodes, can solve the problems of increased leakage current, increased chip size, increased power consumption, etc., to suppress the increase of chip size, achieve high withstand voltage, and reduce leakage current Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, a semiconductor device and a manufacturing method thereof according to an embodiment of the present invention will be described with reference to the drawings.

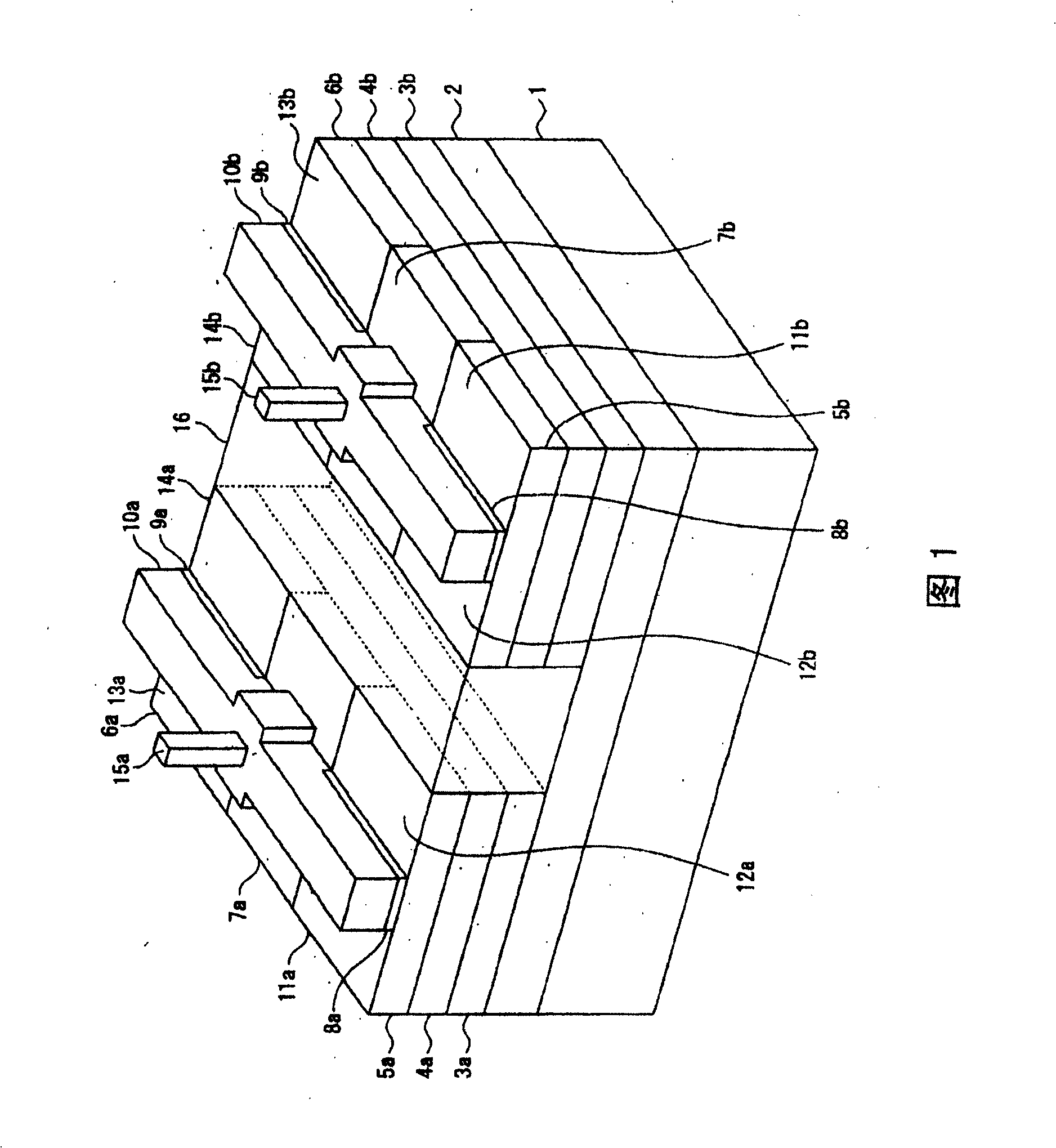

[0046] FIG. 1 is a perspective view showing a schematic configuration of a semiconductor device according to a first embodiment of the present invention.

[0047] In FIG. 1 , an insulating layer 2 is formed on a semiconductor substrate 1 , and single crystal semiconductor layers 3 a and 3 b separated by mesas are stacked on the insulating layer 2 . Further, the single crystal semiconductor layers 5a, 6a separated by mesas are stacked on the single crystal semiconductor layer 3a via the insulating layer 4a, and the single crystal semiconductor layer 5b separated by the mesas is stacked on the single crystal semiconductor layer 3b via the insulating layer 3b. , 6b. In addition, as materials of the semiconductor substrate 1 and the single crystal semiconductor layers 3a, 3b, 5a, 6a, 5b, and 6b, for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com