Viscosity reducing agent for oil

A technology of viscosity reducer and oil products, which is applied in the direction of additives, petroleum industry, lubricating compositions, etc., can solve the problems of viscosity increase, etc., and achieve the effects of reducing the generation of free radicals, reducing viscosity, and reducing internal friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

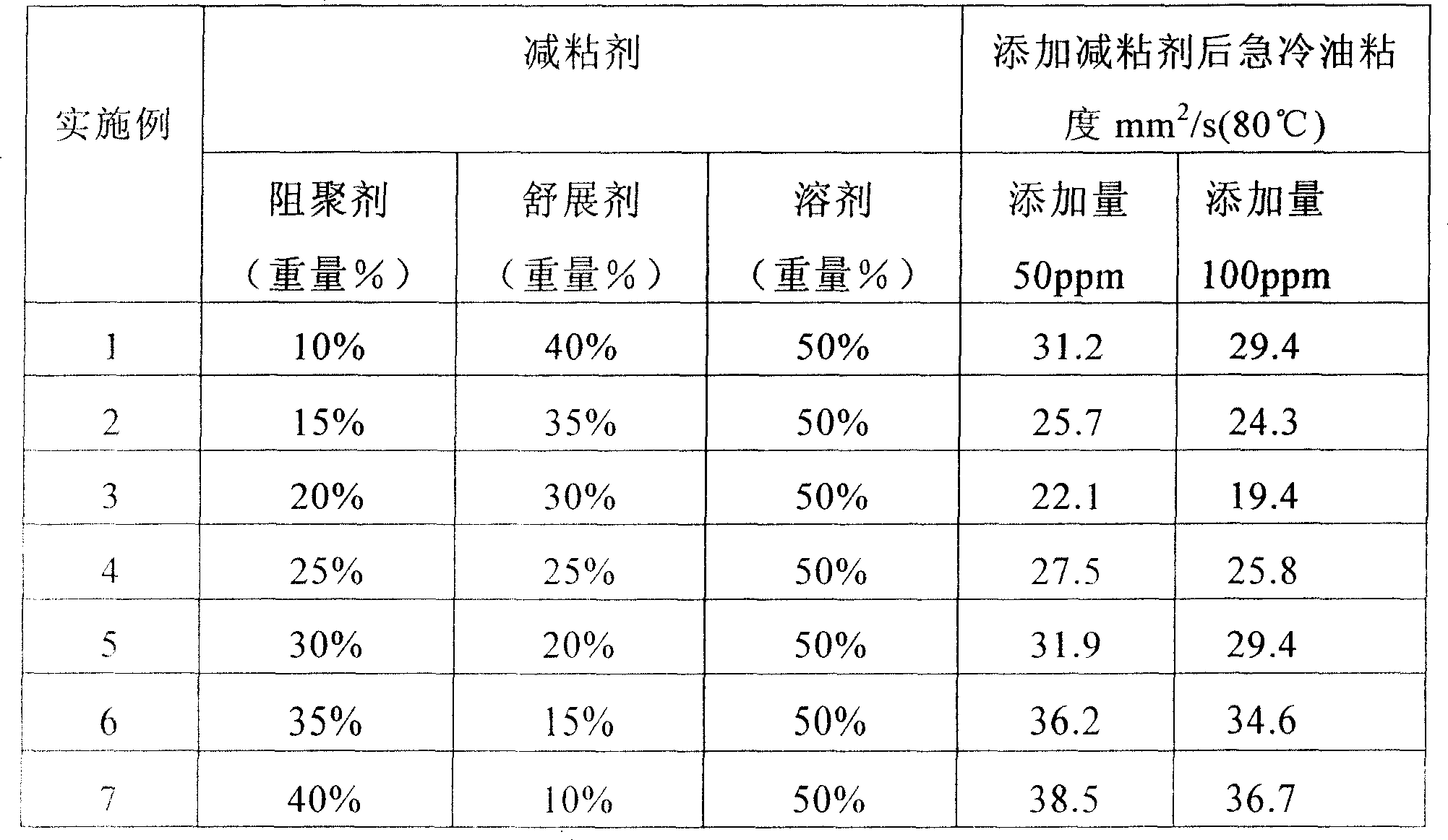

Embodiment 1~7

[0011]

[0012] Note: The viscosity of quenching oil is 43.8mm before adding viscosity reducer 2 / s(80℃)

[0013] In the above examples, the components of Example 1 are the polymerization inhibitor catechol, the stretching agent is trimethyl phosphate, and the hydrocarbon solvent is hexane. The components of Example 2 are the polymerization inhibitor sec-octylphenol, the stretching agent is triethyl phosphate, and the hydrocarbon solvent is cyclohexane. The components of Example 3 are the polymerization inhibitor p-tert-butylphenol, the stretching agent is tributyl phosphate, and the hydrocarbon solvent is kerosene. The components of Example 4 are the polymerization inhibitor p-tert-butylcatechol (TBC), the stretching agent is diisooctyl phosphate, and the hydrocarbon solvent is diesel oil. The components of Example 5 are the polymerization inhibitor p-phenylenediamine, the stretching agent is triphenyl phosphate, and the hydrocarbon solvent is benzene. The components of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com