Method for continuous production of hot galvanizing color-painted steel strip

A color-coated steel plate and hot-dip galvanizing technology, applied in the field of steel plate manufacturing, can solve the problems of steel strip waste, high production and operation costs, and achieve the effects of lower investment costs, lower production and operation costs, and reduced floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

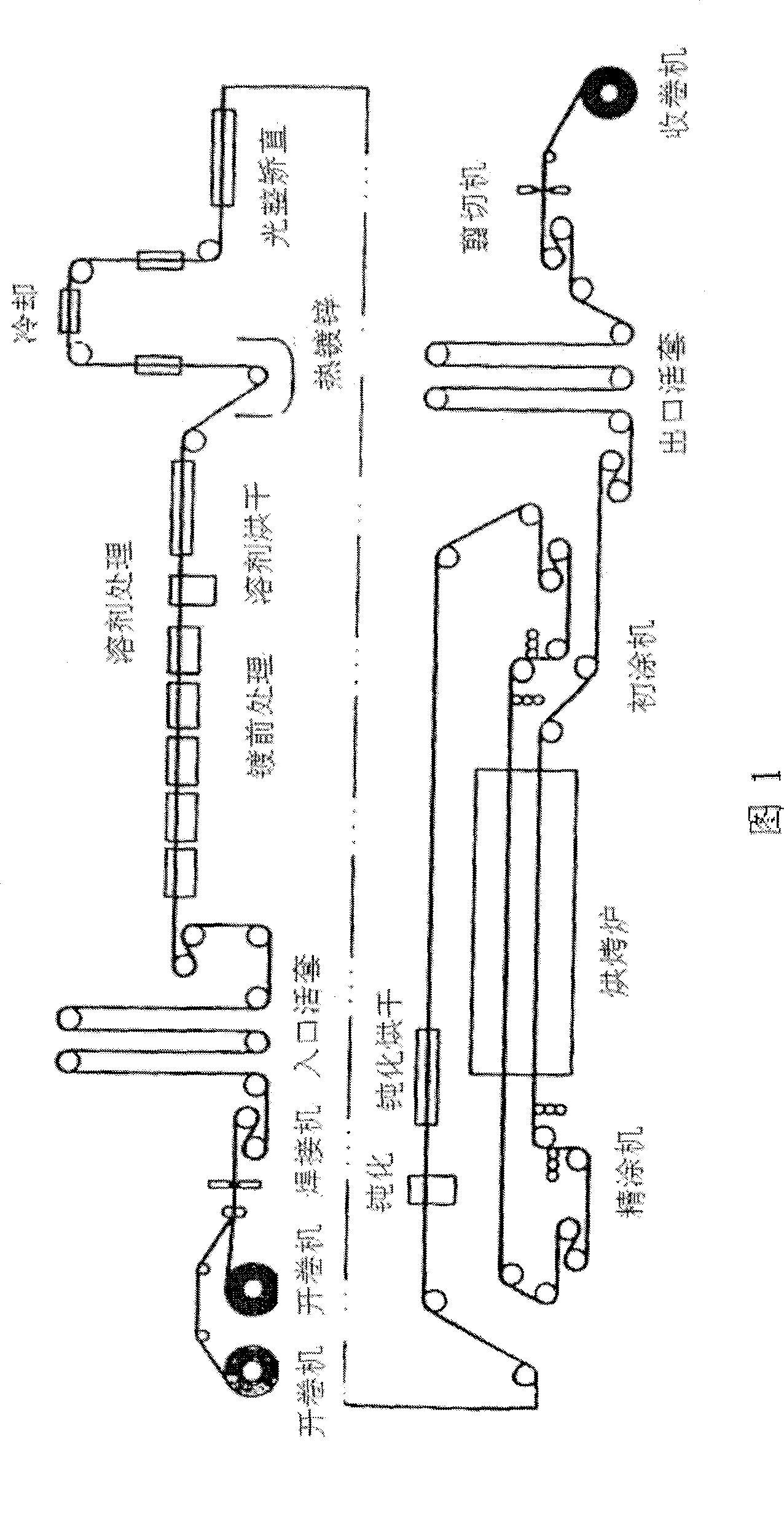

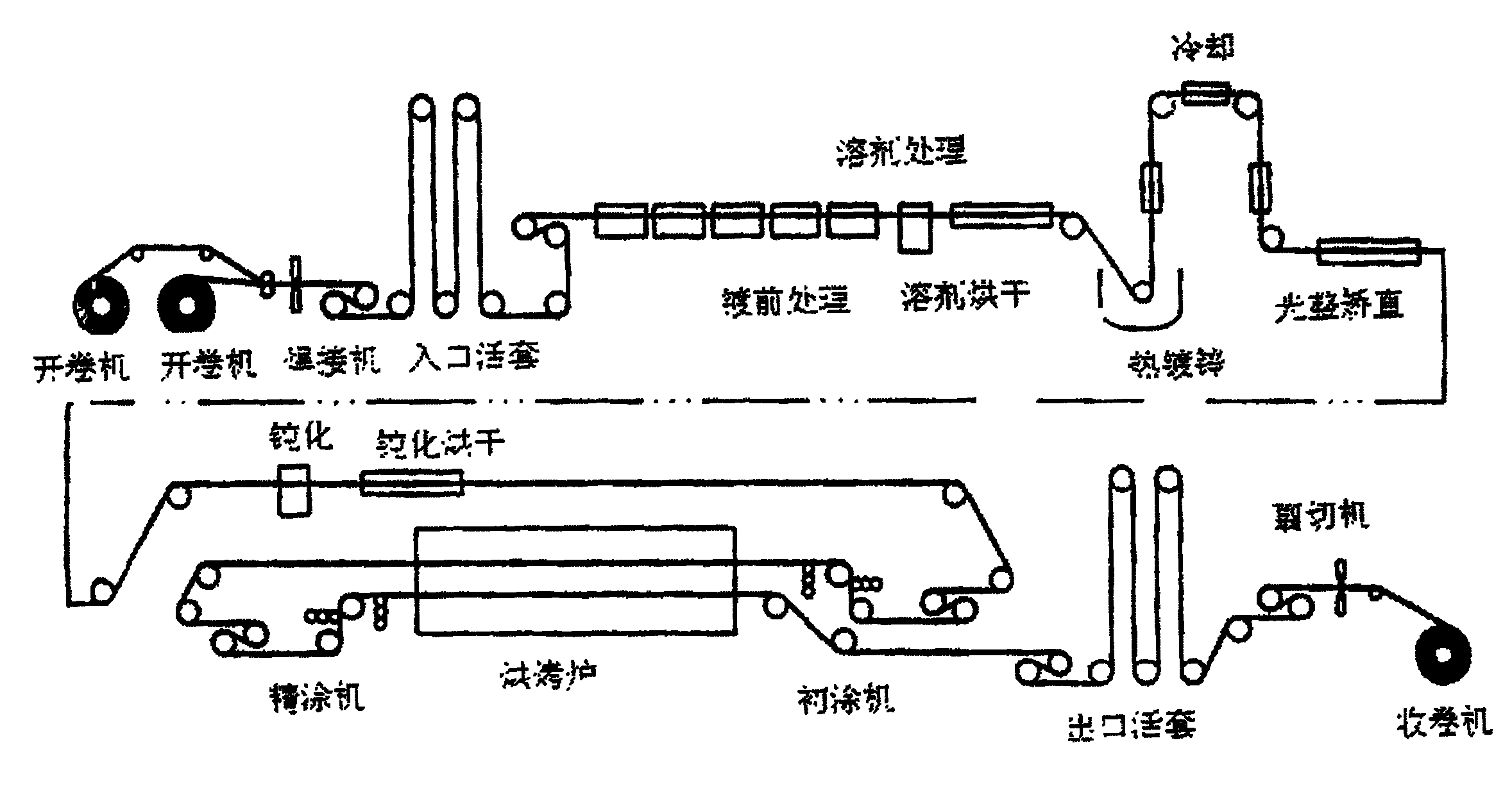

[0038] Please refer to Fig. 1, the method for continuous production of hot-dip galvanized colored coated steel sheets of the present invention may further comprise the steps:

[0039] a. Install the steel coil on the uncoiler to unroll the steel coil into a steel strip;

[0040] b. If the last roll of steel strip is not fully unfolded, go to step c. If the last roll of steel strip is fully unrolled, clamp the head and tail of the two steel coils to the welding machine for welding, so that the front and rear two steel coils will be welded together. Weld together to achieve continuous production;

[0041] c. The steel strip enters the looper storage stage, and the steel strip is sent into the entrance looper;

[0042] d. After the steel strip comes out of the inlet looper, it enters the pre-plating treatment stage. The iron oxide on the surface of the steel strip is removed by hydrochloric acid spray pickling process. contaminated solvents;

[0043] e. The steel strip after p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com