Sorbent of zeolite with carrying silver, preparation method and application thereof

A silver-loaded zeolite and adsorbent technology, applied in chemical instruments and methods, other chemical processes, separation/purification of carboxylic acid compounds, etc., can solve the corrosion of refining equipment, uneven distribution of coarse pores, and reduce the use efficiency of adsorbents and other problems, to achieve the effect of simple preparation method and high industrialization prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Put 80 grams of acid-resistant base zeolite into a 50mL autoclave, and add 40ml of 0.5mol / L ion-exchange silver-carrying Ag + Solution (AgNO 3 solution), heated to 140°C, and the constant temperature time was 6 hours. After the ion exchange silver loading was completed, the adsorbent was taken out, washed with distilled water, and dried in an oven at 80°C. EDX analysis was performed on the ion-exchange silver-loaded adsorbent, and the results obtained are shown in Table 1:

[0039] Table 1

[0040] element content Al (mol%) 2.61 Si (mol%) 32.57 Ag (mol%) 2.75 Na(mol%) 0.27 O (mol%) 61.8 Ag / Al 1.05 SiO 2 / Al 2 o 3 25 Ag wt% 13.06

Embodiment 2

[0042] Put the acid-resistant zeolite adsorbent into the ion exchange column, the solid volume of the exchange column is 20mL, and the solution concentration is 0.1mol / L Ag + Solution (AgNO 3 Solution), continue to flow through the exchange column, the duration is 24 hours, the temperature is 80 ℃, and the flow velocity is 4 m / s. The EDX method is used to analyze the composition of the ion-exchange silver-loaded sorbent. The results obtained are shown in Table 2:

[0043] Table 2

[0044] element content Al (mol%) 2.87 Si (mol%) 31.07 Ag (mol%) 1.55 Na(mol%) 0.06 O (mol%) 64.45 Ag / Al 0.54 SiO 2 / Al 2 o 3 21.65 Ag wt% 7.8

Embodiment 3~11

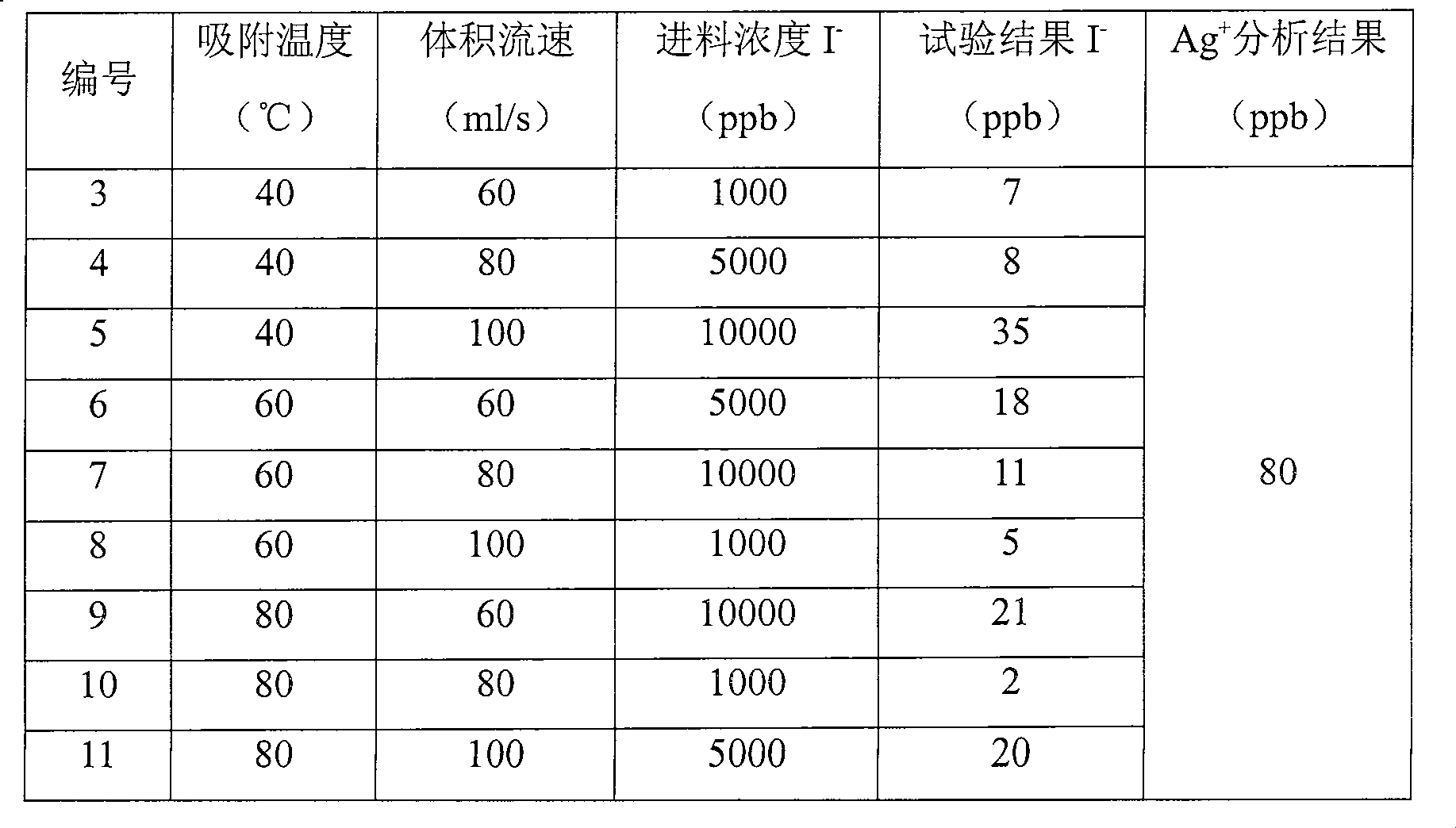

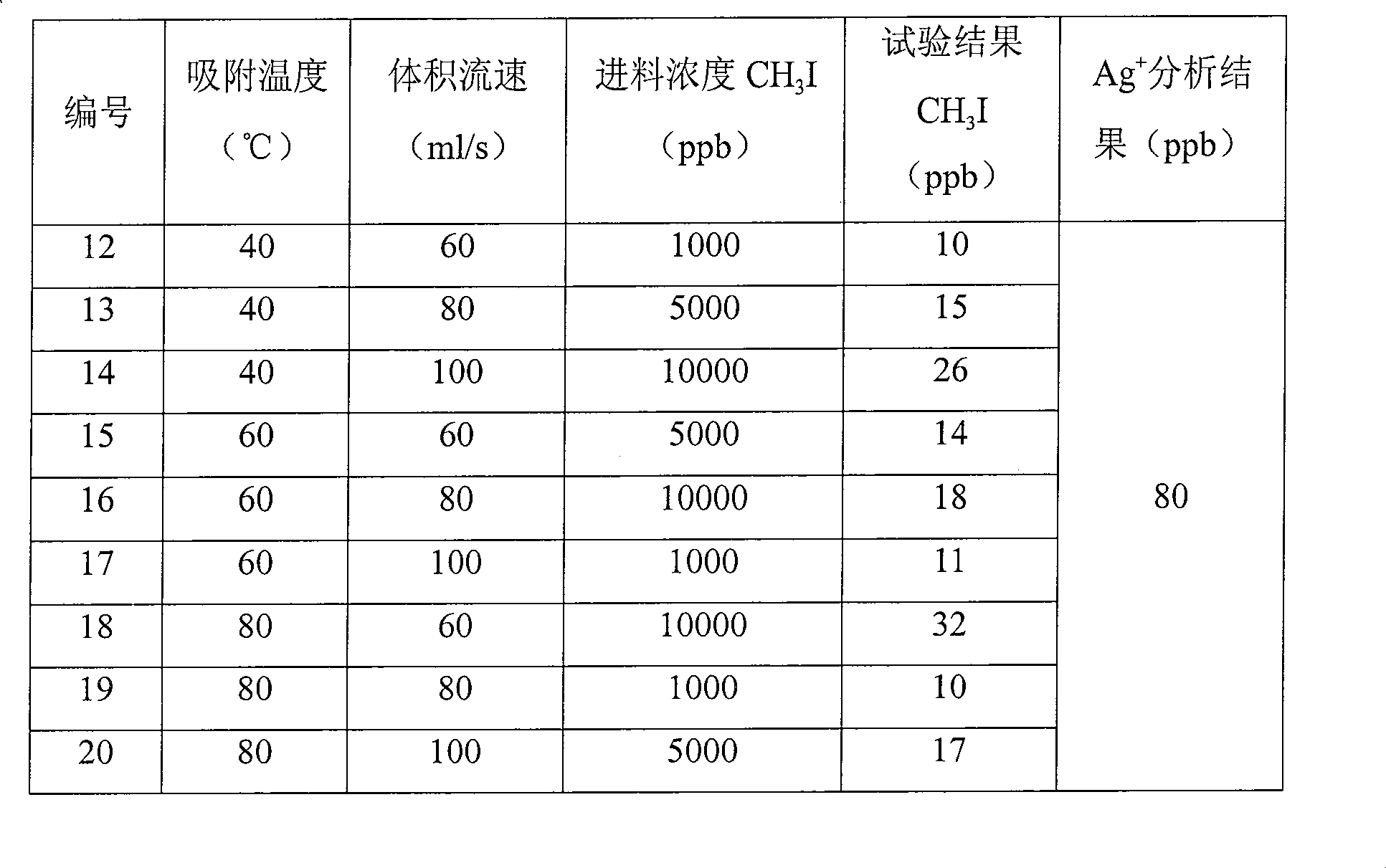

[0046] Take by weighing the ion-exchange silver-loaded adsorbent 16g (about 20mL) that embodiment 2 obtains, carry out the test of removing trace inorganic iodide in the acetic anhydride product under the conditions listed in table 3 respectively in the ion-exchange column, after the test, B The analysis results of inorganic iodide content and silver content in the acid anhydride product are listed in Table 3, to prove that the ion-exchange silver-loaded adsorbent has a good effect on removing trace amounts of inorganic iodide in the acetic anhydride product.

[0047] table 3

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com