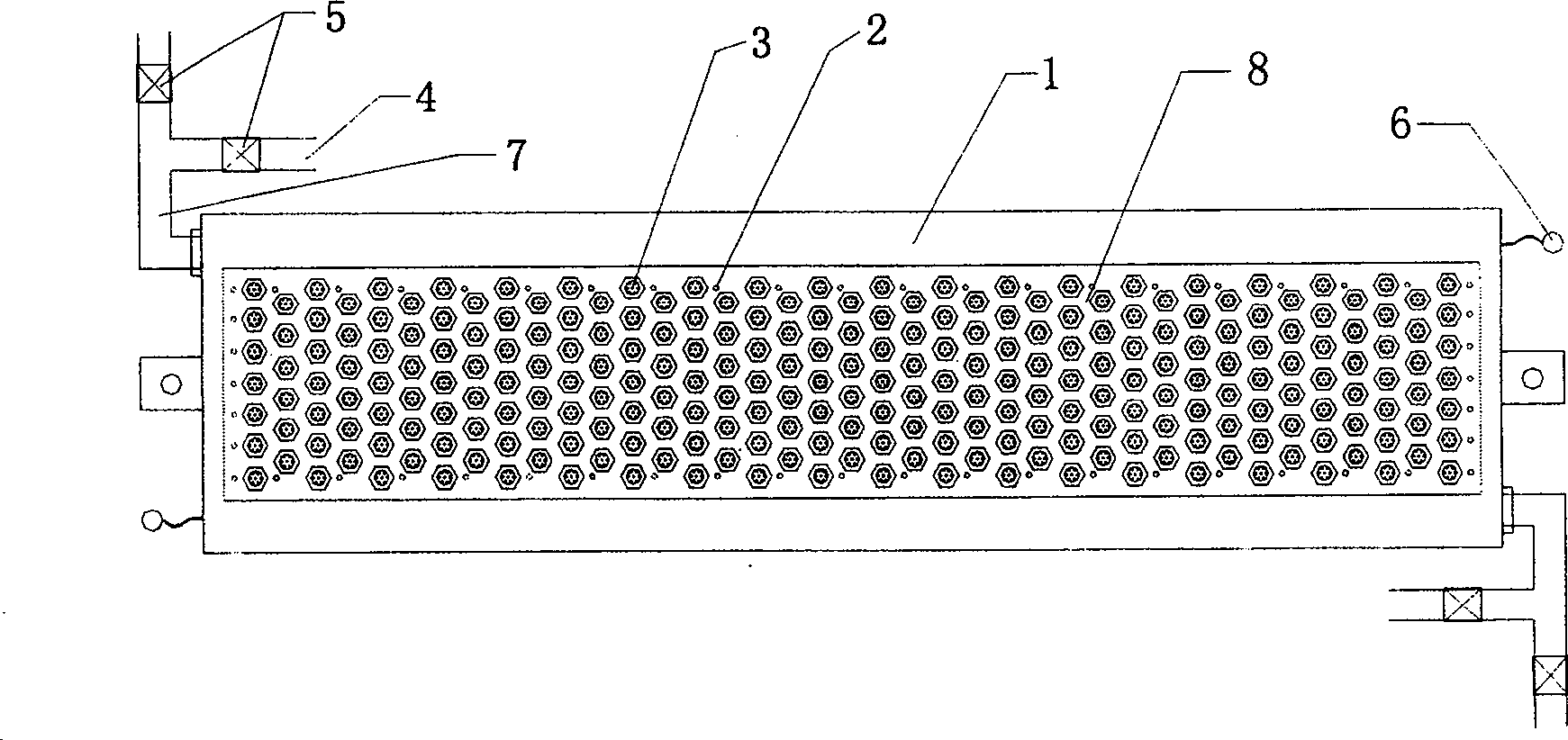

Method and apparatus for heating thin-band continuous-casting crystallized roller

A technology of continuous casting crystallization and heating method, which is applied in the field of crystallization roller heating for continuous casting of metal sheets, and can solve the problems of large energy consumption, belt breakage, and impact on production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

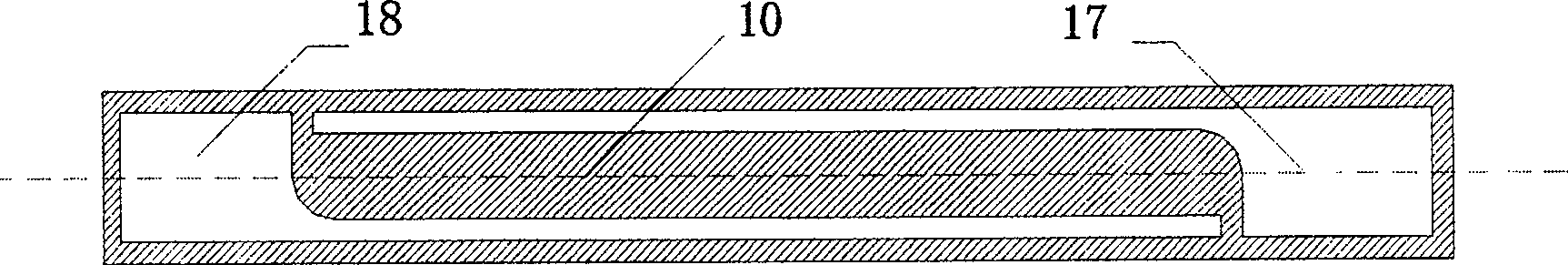

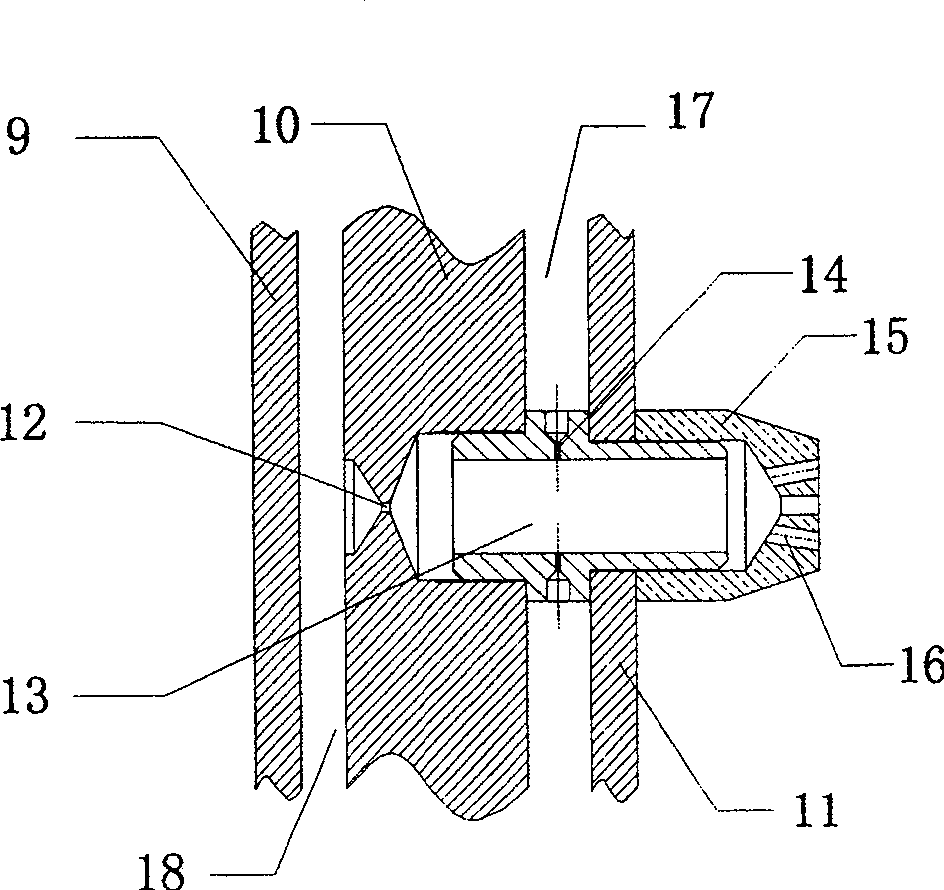

Method used

Image

Examples

Embodiment 1

[0044] Hydrogen is used as fuel gas, and oxygen is used as combustion-supporting gas. The flow ratio of hydrogen and oxygen is chemical reaction ratio 1:0.95, and the pressure of hydrogen is 30PSI. The flame length of the obtained flame curtain wall is 30mm, and the flame temperature is 1200°C; when the pressure of the hydrogen gas is increased to 50 PSI, the flame length of the obtained flame curtain wall is 50mm, and the flame temperature is 1600°C. The intensity and length of all the flames of the flame curtain wall formed by the heating technology of the present invention are similar, and the temperature field is uniform. The heating effect is good.

Embodiment 2

[0046] Natural gas is used as fuel gas, and oxygen is used as combustion-supporting gas. The flow ratio of natural gas and oxygen is a chemical reaction ratio of 1:1, and the pressure of natural gas is 45 PSI. The flame length of the obtained flame curtain wall is 50mm, and the flame temperature is 700°C; when the pressure of the hydrogen gas is increased to 50 PSI, the flame length of the obtained flame curtain wall is 80mm, and the flame temperature is 1000°C. The intensity and length of all the flames of the flame curtain wall formed by the heating technology of the present invention are similar, but the length of the flame is longer than that of the hydrogen-oxygen flame. The temperature field of the flame curtain wall is uniform and the heating effect is good.

Embodiment 3

[0048] Ethanol is used as fuel, and air is used as combustion-supporting gas. The flow ratio of ethanol to air is a chemical reaction ratio of 1:0.9. Considering that ethanol is a liquid fuel, a hydraulic pump is used as a power source, and the pressure of ethanol is 2.0kg / cm 2 . Control the flow of compressed air based on the flow of ethanol to form a chemical reaction ratio of 1:0.9-1:0.98. The flame length of the obtained flame curtain wall is 80mm, and the temperature of the flame is 700°C; when the pressure of ethanol rises to 3.0kg / cm 2 , the flame length of the obtained flame curtain wall is 150mm, and the temperature of the flame is 1000°C. The intensity and length of all the flames of the flame curtain wall formed by the heating technology of the present invention are similar, but the length of the flame is longer. The temperature field of the flame curtain wall is uniform and the heating effect is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com