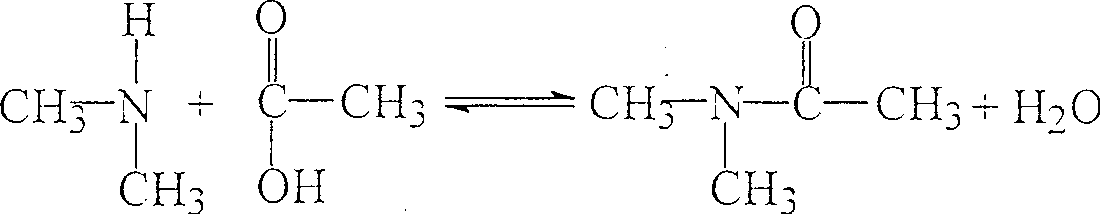

Method for synthesizing N,N dimethyl acetamide in high purity

A technology of dimethylacetamide and dimethylamine, applied in the field of continuous synthesis of N, can solve the problems of complex DMAC refining process, harsh reaction conditions, low product yield and the like, and achieves full utilization of reaction heat, high product yield, Refinement for simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Glacial acetic acid and dimethylamine are in an equal molar ratio, and 600 g of glacial acetic acid and 450 g of dimethylamine are continuously added to the salt-forming reaction tower, and the neutralization and salt-forming reaction is carried out at 35-55° C. under normal pressure. Next, add 300g of the salt-forming reaction product and 12g of zinc chloride to the reactive distillation tower, raise the temperature, and then continuously enter the reactive distillation tower with 50g / h of the salt-forming reaction product and 18L / h of dimethylamine. The decomposition reaction is carried out under normal pressure, and the DMAC and water generated by the decomposition are continuously extracted from the top of the reactive distillation tower, and the continuous rectification and purification process under normal pressure obtains 831g of DMAC product with a purity of 99.95%.

Embodiment 2

[0025] According to the same procedure of Example 1, except adding 12g of zinc acetate, all the other conditions remained unchanged, and 770g of DMAC product was obtained, and its purity was 99.80%.

Embodiment 3

[0027] According to the same procedure of Example 1, except that 12g of magnesium chloride was added, all the other conditions remained unchanged, and 761g of DMAC product was obtained, and its purity was 99.68%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com