Epoxy bleedout-preventing agent and method, wiring substrate and semiconductor package

A technology for epoxy resin and wiring substrate, which is applied in the fields of semiconductor devices, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc. The effect of bleed-out of epoxy resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

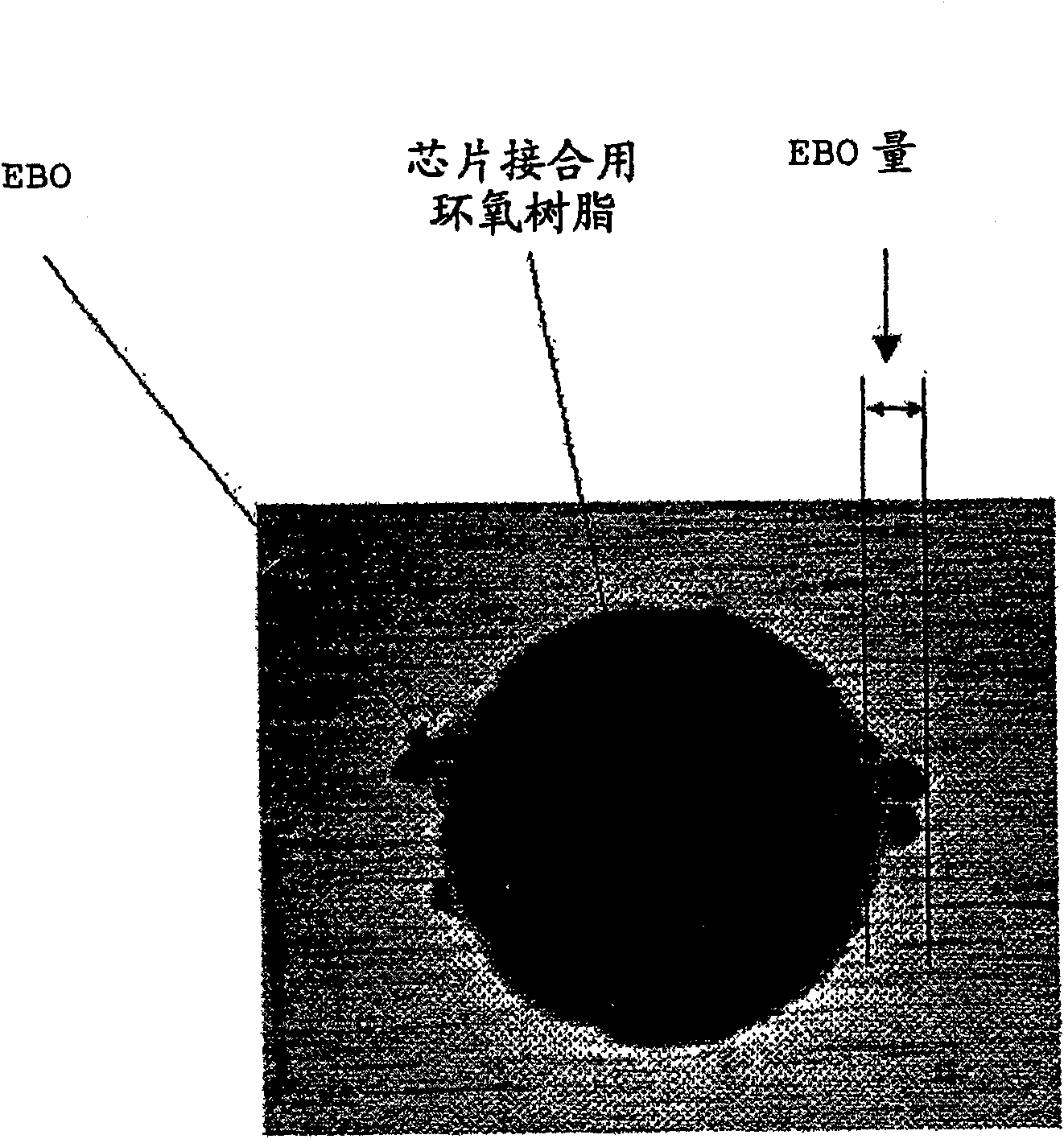

Image

Examples

Embodiment 1~10

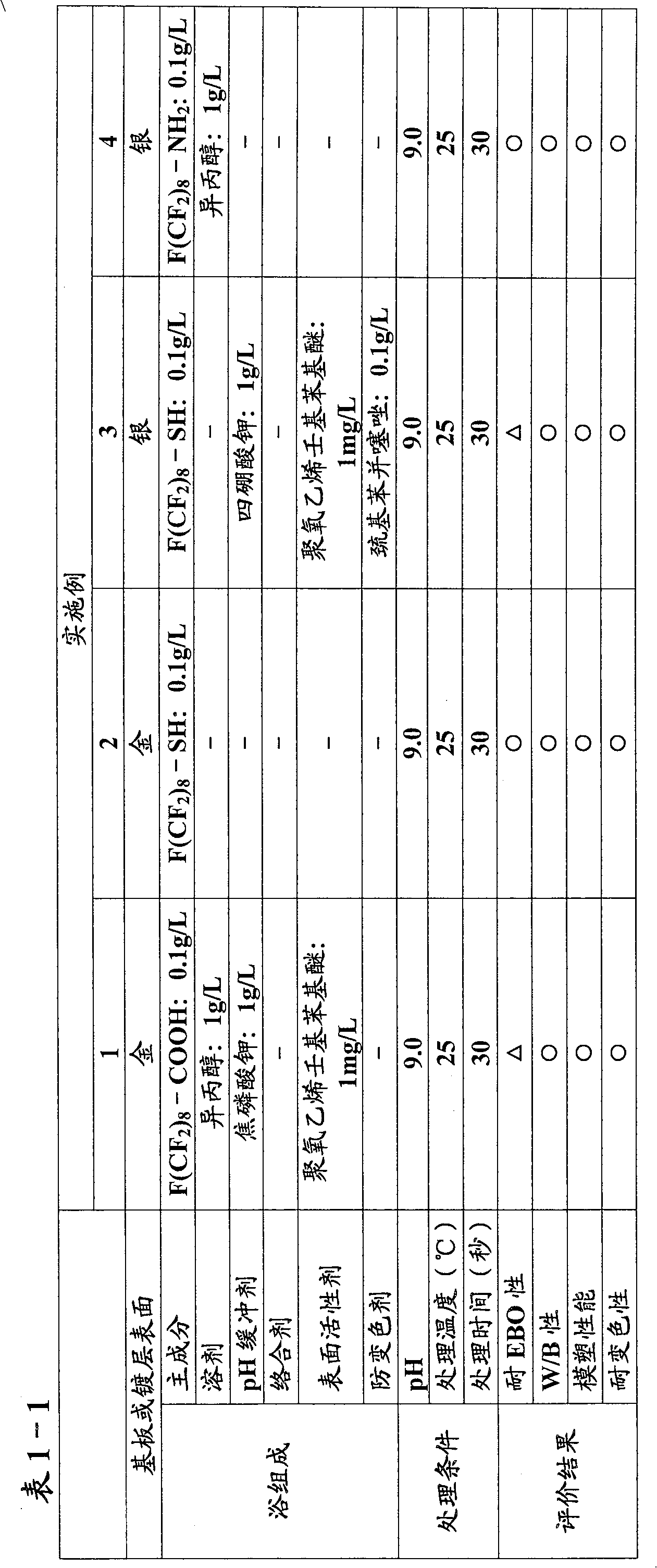

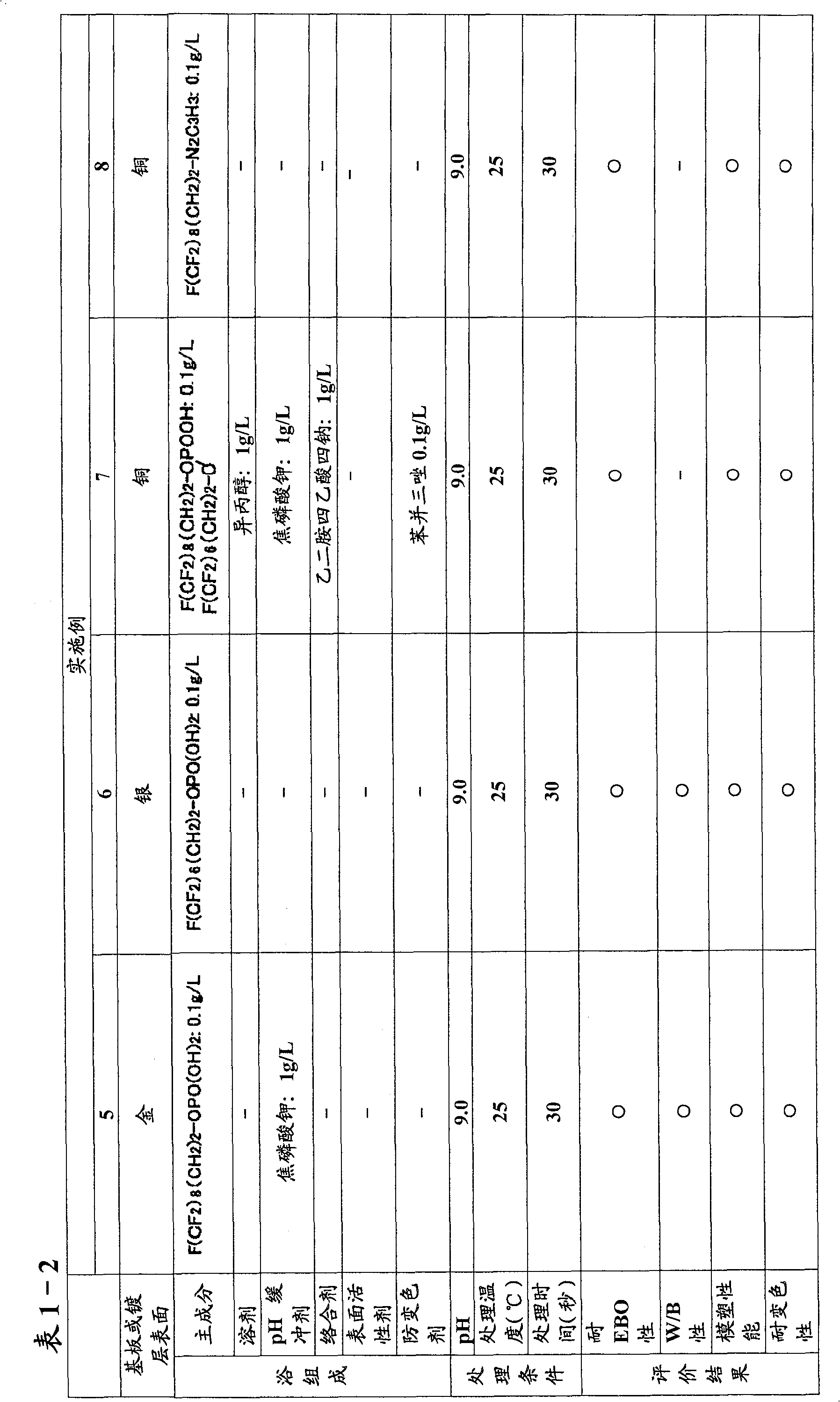

[0047] On a lead frame substrate made of a copper alloy (Cu: 97.7%-Sn: 2.0%-Ni: 0.2%-P: 0.03%), copper strike plating is performed as a base to improve adhesion, and then on the lead frame Any of gold plating, silver plating, and copper plating is performed on the entire surface. Then, the epoxy resin bleed prevention treatment as described in Table 1 was performed by dipping.

[0048] In addition, the polar group-N 2 C 3 h 3 , -N 3 C 2 h 2 , -N 4 CH is 1-imidazolyl, 1,2,3-triazol-1-yl, 1-tetrazolyl, respectively.

[0049] Die bonding was performed on these substrates, and epoxy resin bleeding resistance (EBO resistance), wire bonding performance (W / B property), molding performance, and discoloration resistance were evaluated. The results are shown in Table 1. In Table 1, [-] in the bath composition means not added, and [-] in the evaluation means not to be evaluated.

[0050] Evaluation of epoxy resin bleed resistance was carried out in accordance with the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com