Organometallic complex, light-emitting solid, organic electroluminescent element and organic electroluminescent display

An electroluminescent element and organometallic technology, applied in the direction of electroluminescent light sources, platinum-based organic compounds, platinum-group organic compounds, etc., can solve problems such as few strong phosphorescent materials, narrow selection range, and insufficient phosphorescence efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0427] The Pt(dpt)(o2Fph) synthesized in Synthesis Example 1 was made into a thin film (luminescent solid) with a thickness of 50 nm by co-evaporation method on the glass substrate, and was doped into CBP at 2% according to the vapor deposition rate. According to the following assay method, with the known PL quantum yield (PL quantum yield: 22%) of three (8-hydroxyquinoline) aluminum (Alq3) thin film as reference, calculate the PL quantum yield of this thin film (luminescent solid) rate (photoluminescence).

[0428] That is, excitation light (365 nm constant light) from a light source is obliquely irradiated onto a thin film sample on a transparent substrate. The PL spectrum of the thin film was measured by a spectroradiometer (Minolta, CS-1000) 104, and the number of PL photons [P(sample)] was calculated from the conversion of the PL spectrum. While performing luminescence measurement, the total intensity [I(sample)] of excitation light transmitted and reflected from the sam...

Embodiment 2-30,30a-c, and comparative Embodiment 1-7

[0431] In addition to changing the organometallic complex as the luminescent material from Pt (dpt) (o2Fph) to the organometallic complexes listed in Table 6-Table 8 (synthesized by the above-mentioned synthesis examples), in the same example 1 Under the same conditions, measure the quantum yield of phosphorescence of the formed thin film (luminescent solid). The results are shown in Table 6 to Table 8.

[0432] Table 6

[0433] Luminescent material

[0434] Table 7

[0435] Luminescent material

[0436] Table 8

[0437] Luminescent material

[0438] From the results shown in Table 6 to Table 8, it is obvious that the phosphorescent film made of the organometallic complex of the present invention has a very high quantum yield of phosphorescent emission.

Embodiment 31

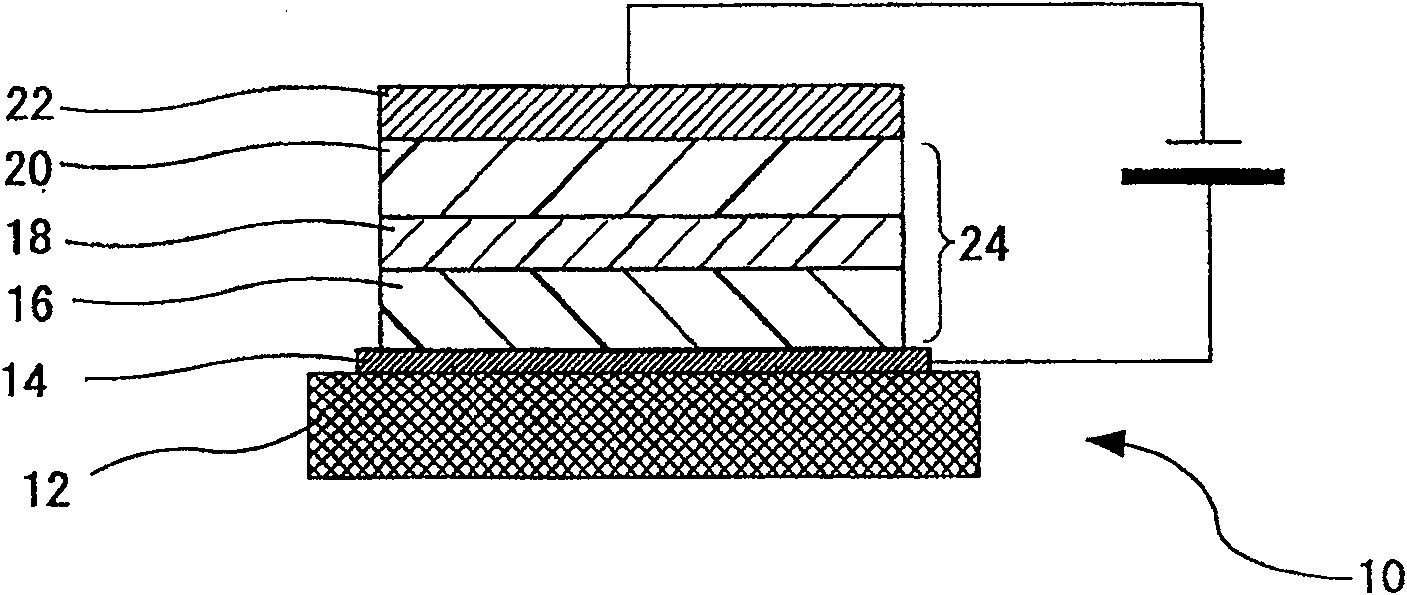

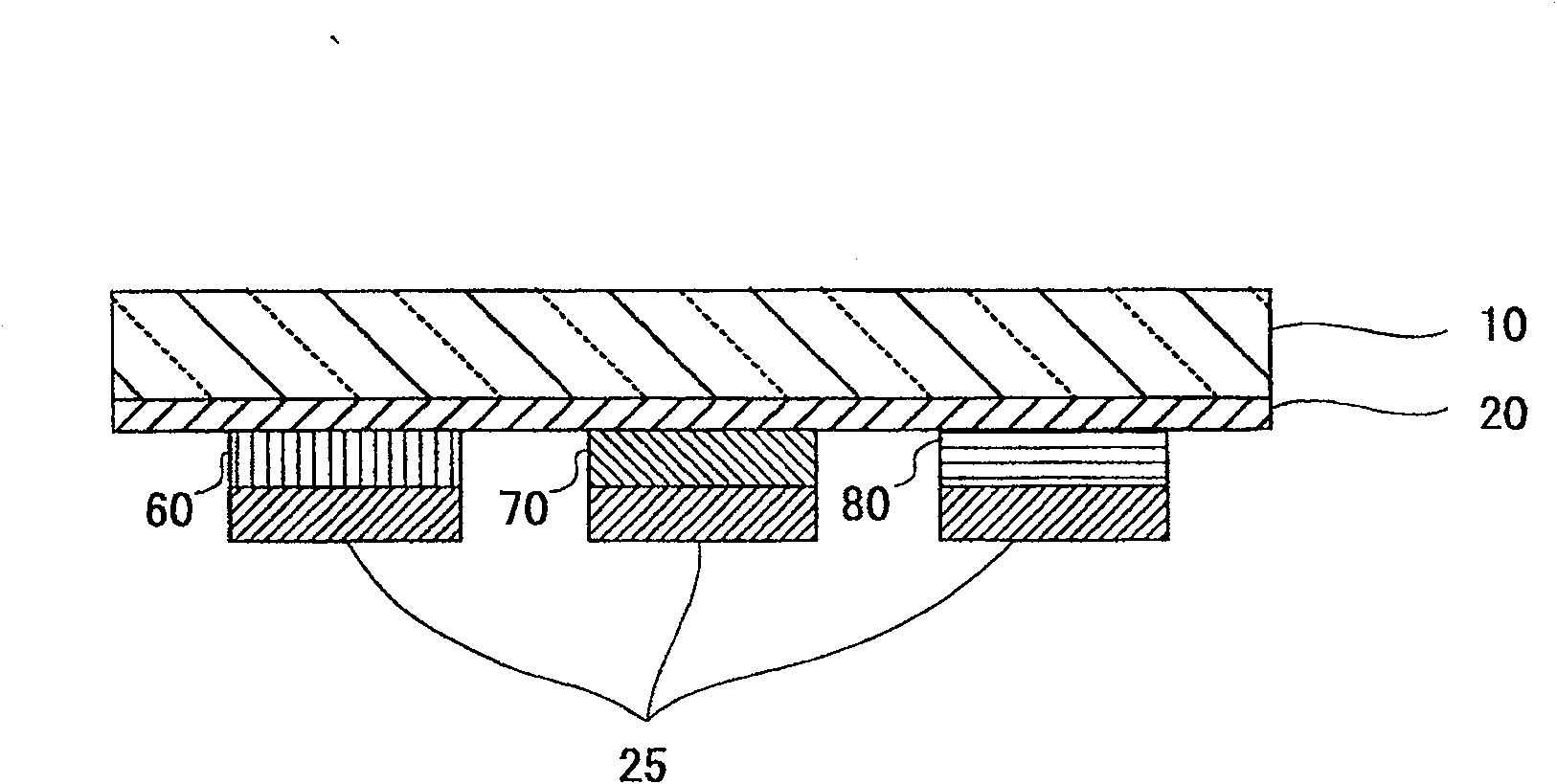

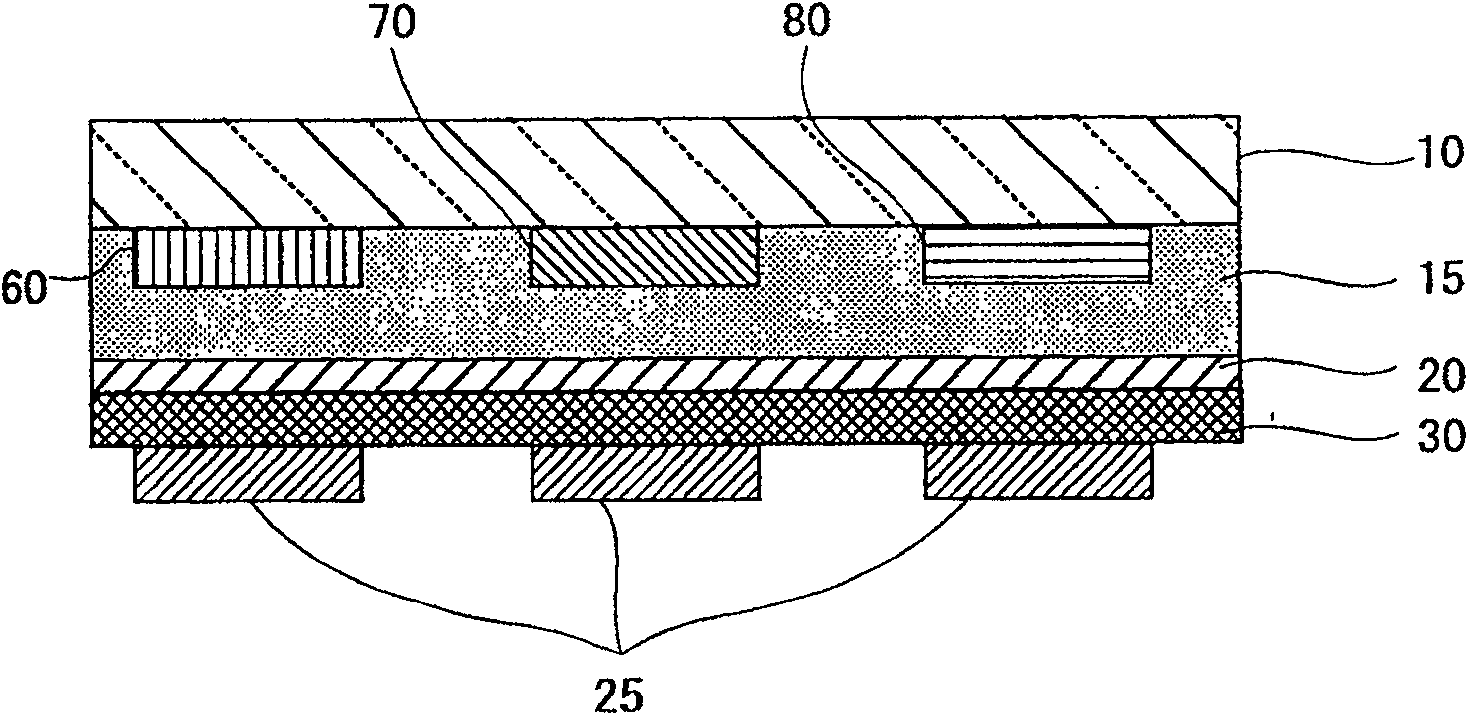

[0440] A multilayer organic EL device was fabricated using the obtained organometallic complex Pt(dpt)(o2Fph) as a light-emitting material for the light-emitting layer. The glass substrate with the ITO electrodes attached thereon was cleaned with water, acetone and isopropanol. Vacuum vapor deposition equipment (vacuum degree=1×10 -4 Pa, substrate temperature = room temperature) 4,4',4"-tris(2-naphthylphenylamino)triphenylamine (2-TNATA) as a positive hole injection layer is formed on the ITO electrode to a thickness of Be 4nm.Then form the above-mentioned NPD as the positive hole transport layer on the positive hole injection layer, to a thickness of 10nm.Form the above-mentioned BCP as the positive hole blocking layer on the light-emitting layer, to a thickness of 20nm.In this positive Form the above-mentioned Alq3 as the electron transport layer on the hole blocking layer, to a thickness of 20nm.Then on the electron transport layer, the vapor deposition of LiF to a thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal quantum efficiency | aaaaa | aaaaa |

| fluorescence quantum yield | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com