Organometallic complex, light-emitting solid, organic electroluminescent element and organic electroluminescent display

An electroluminescent element and organometallic technology, applied in electroluminescent light sources, platinum group organic compounds, platinum group organic compounds, etc., can solve the problems of narrow selection range, insufficient phosphorescence efficiency, and few strong phosphorescence materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0432] The Pt(dpt)(o2Fph) synthesized in Synthesis Example 1 was made into a thin film (luminescent solid) with a thickness of 50 nm by co-evaporation method on a glass substrate, and it was doped into CBP at 2% according to the vapor deposition rate. According to the following measurement method, with the known PL quantum yield (PL quantum yield: 22%) of the tris(8-hydroxyquinoline) aluminum (Alq3) film as a reference, calculate the PL quantum yield of the film (luminescent solid) Rate (photoluminescence).

[0433] That is, the excitation light (365 nm constant light) from the light source is obliquely irradiated on the thin film sample on the transparent substrate. The PL spectrum of the film is measured by a spectroradiometer (Minolta, CS-1000) 104, and the number of PL photons [P(sample)] is calculated from the PL spectrum conversion. While performing the luminescence measurement, the total intensity of the excitation light transmitted and reflected from the sample is detected...

Embodiment 2-30,30a-c, and comparative Embodiment 1-7

[0436] In addition to changing the organometallic complexes as the luminescent material from Pt(dpt)(o2Fph) to the organometallic complexes listed in Table 6 to Table 8 (synthesized by the above synthesis example), the following 1 Measure the phosphorescence quantum yield of the formed thin film (luminescent solid) under the same conditions. The results are shown in Table 6 to Table 8.

[0437] Luminescent material

[0438] Luminescent material

[0439] Luminescent material

[0440] From the results shown in Table 6 to Table 8, it is obvious that the phosphorescent film made of the organometallic complex of the present invention has a very high phosphorescent emission quantum yield.

Embodiment 31

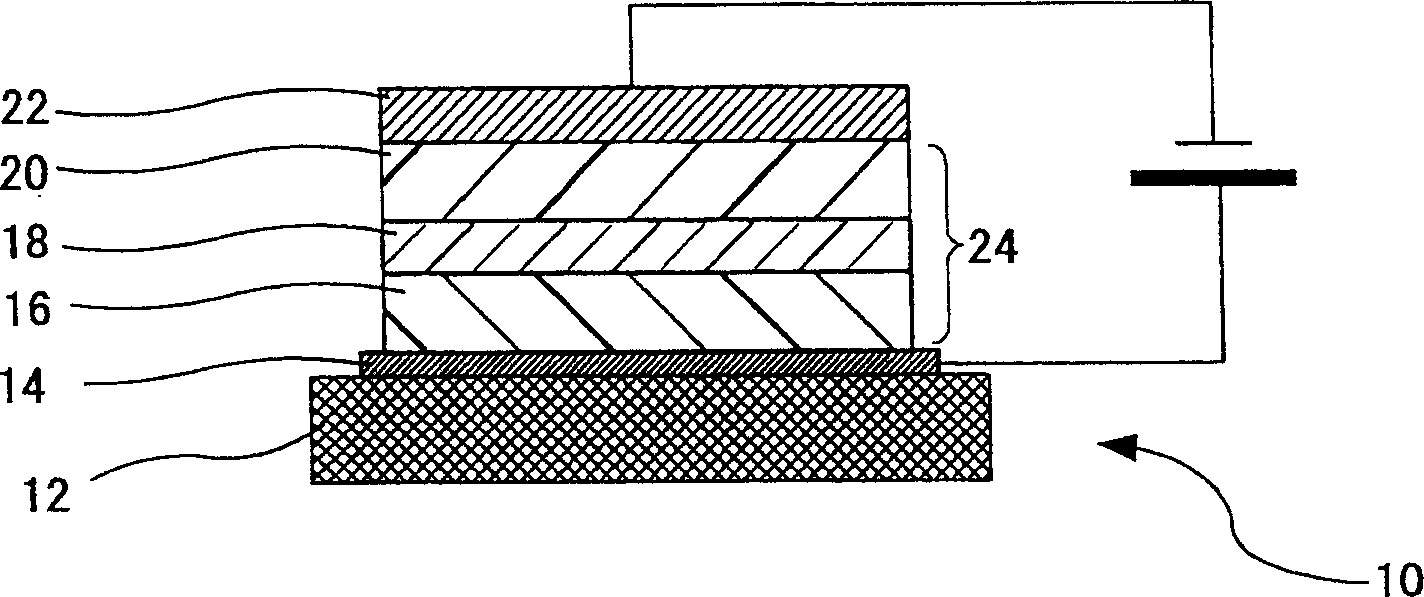

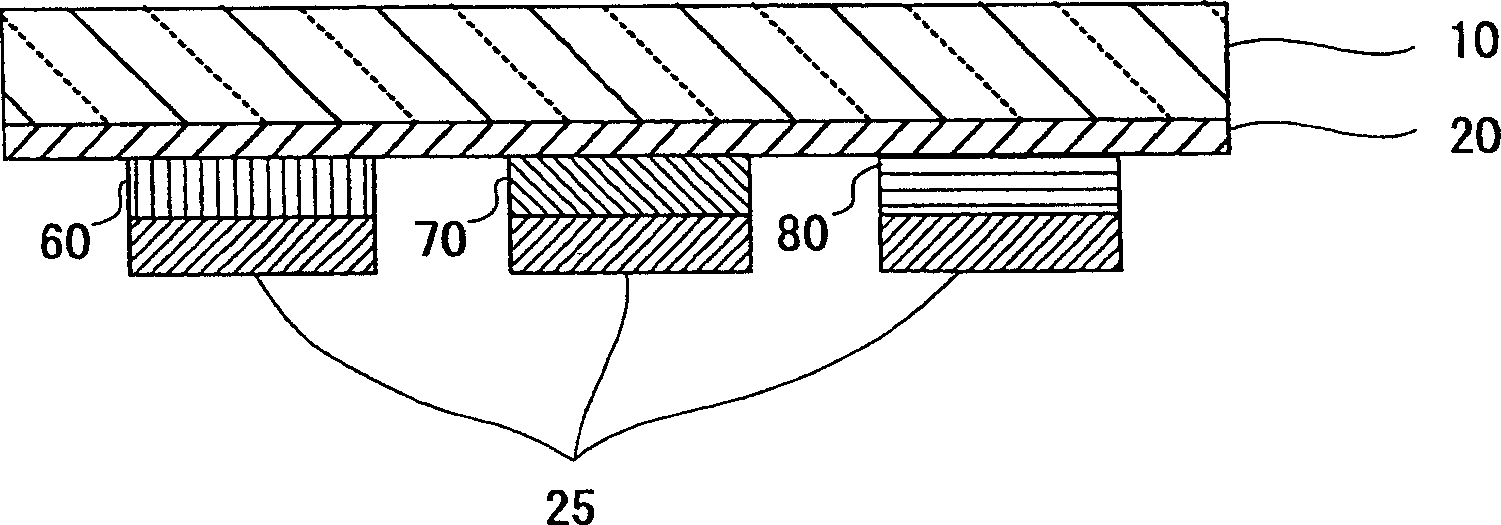

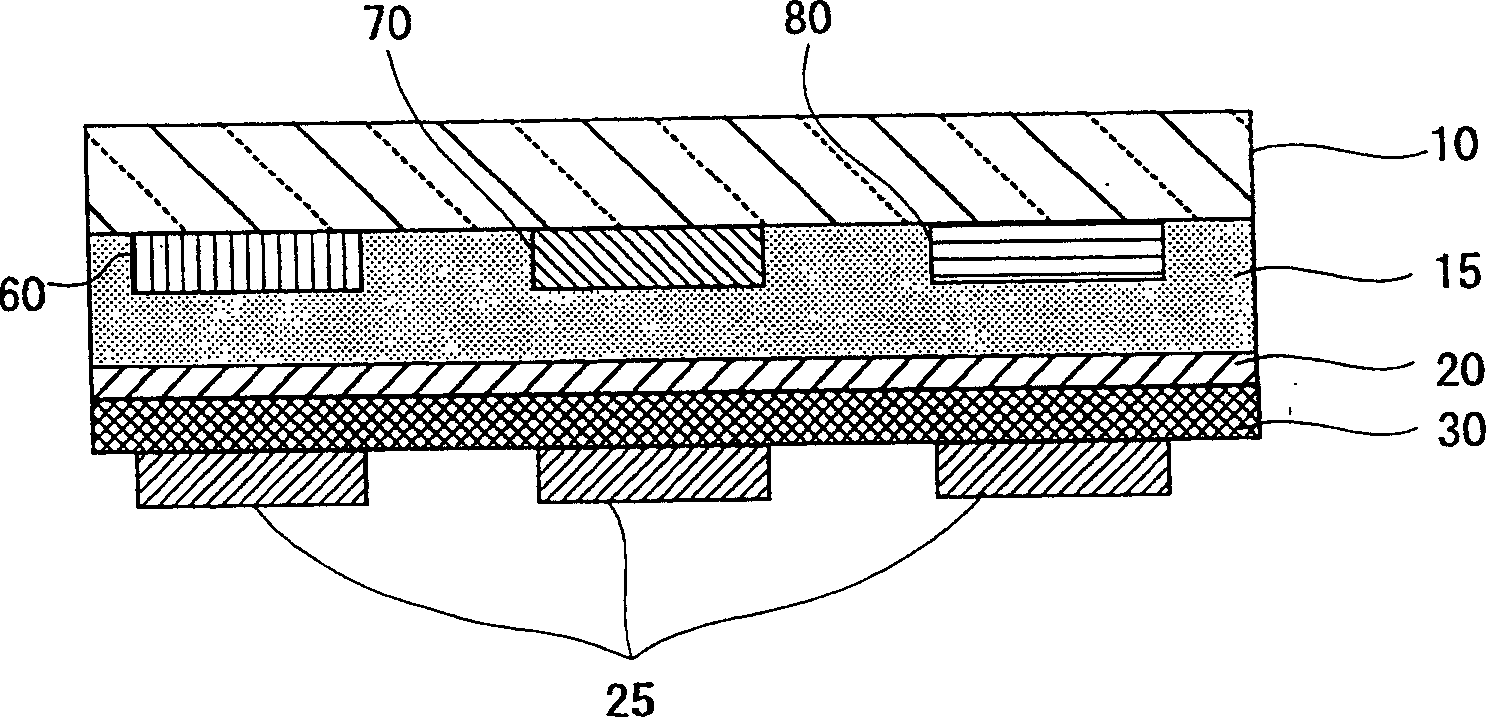

[0442] Using the obtained organometallic complex Pt(dpt)(o2Fph) as the light-emitting material of the light-emitting layer, a multilayer organic EL device was manufactured. Use water, acetone and isopropanol to clean the glass substrate on which the ITO electrode is attached. Use vacuum vapor deposition equipment (vacuum = 1×10 -4 Pa, substrate temperature = room temperature) 4,4',4"-tris(2-naphthylphenylamino)triphenylamine (2-TNATA) as a positive hole injection layer is formed on the ITO electrode to the thickness The NPD as a positive hole transport layer is then formed on the positive hole injection layer to a thickness of 10 nm. The BCP as a positive hole blocking layer is formed on the light-emitting layer to a thickness of 20 nm. The above-mentioned Alq3 as an electron transport layer is formed on the hole blocking layer to a thickness of 20nm. Then LiF is vapor-deposited on the electron transport layer to a thickness of 0.5nm, and finally aluminum is vapor-deposited to a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com