Permanent self-cleaning glass with visible light responsibility and preparation method thereof

A self-cleaning, glass technology, applied in the field of functional materials, can solve the problems of limiting the application space of self-cleaning glass, and achieve the effects of good visible light response activity, good hydrophilicity, and easy control of film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

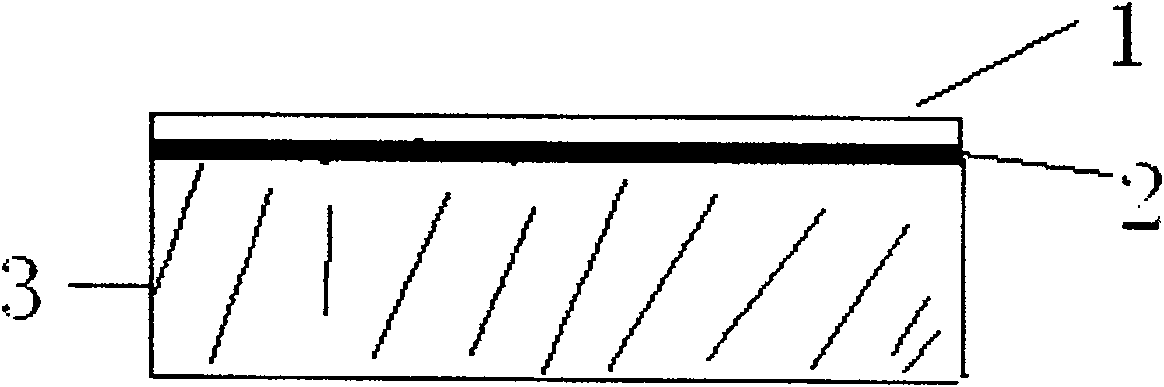

Image

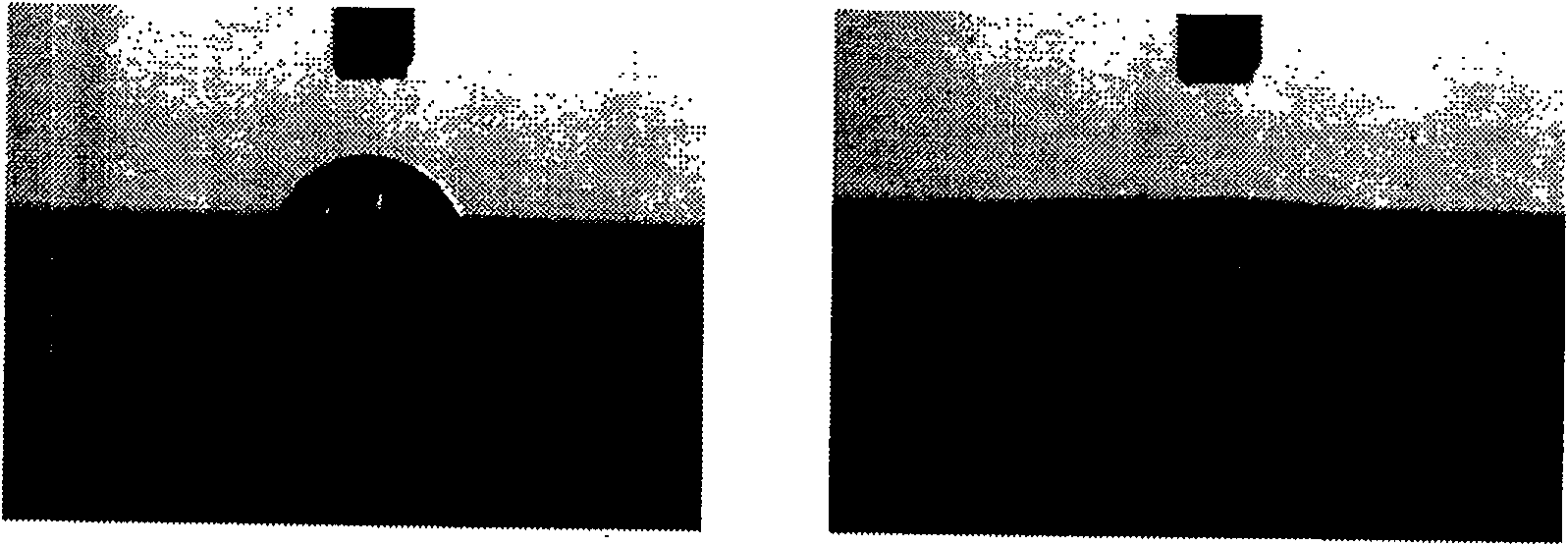

Examples

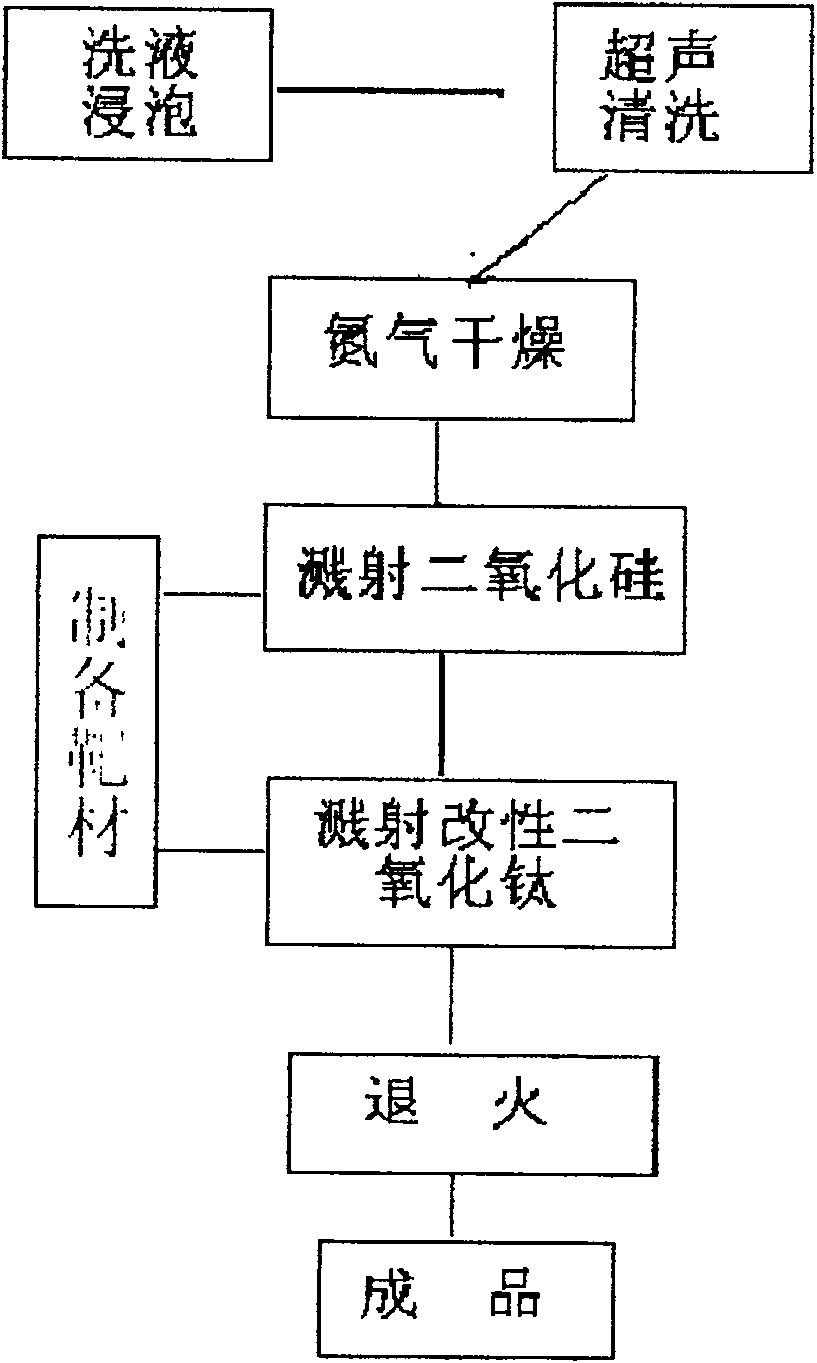

Embodiment 1

[0022] Cut the glass to the desired size. Clean the stains on the glass surface with water; soak the cleaned glass in the washing solution for 3 hours, and then use deionized water to ultrasonically clean it 5 times, 10 minutes each time. After cleaning, dry it with nitrogen; use radio frequency magnetron sputtering to sputter a layer of nano silicon dioxide film on the glass surface. The sputtering target is pure silicon dioxide, the sputtering atmosphere is pure argon, the sputtering pressure is 0.8Pa, the sputtering power is 180W, the glass substrate temperature is 150°C, the sputtering time is 4 hours, and the sputtering nanometer The thickness of silicon oxide film is about 30nm; titanium dioxide powder and tungsten trioxide powder are mixed and ball milled in proportion (the molar ratio of tungsten to titanium is 1:19), and then sintered at a high temperature in a sintering furnace; the surface is coated with nano silicon dioxide film The titanium dioxide hybrid target ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com