Methods of making a niobium metal oxide and oxygen reduced niobium oxides

A technology of niobium oxide and niobium powder, which is applied in the field where niobium suboxide with excellent morphology is required, can solve the problems of difficulty in preparing final products, increased pollution, and multiple wastes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0155] The above-described aspects of the present invention include many advantages, including superior capacitor grade materials and fabrication methods, thereby producing capacitor grade metal materials that can be used to form high performance capacitors characterized by high capacitance and low DC leakage. Morphological and other observable or measurable microstructural characteristics of the capacitor grade materials of the present invention that enhance the enhanced performance characteristics of capacitors made therefrom include: controlled primary particle size, high flowability, high purity, high BET surface area, uniform particle size Size distribution, Scott density, extrudability, crush strength, morphology, stability, dopant content, etc. The valve metal oxide particles formed by deagglomerating the agglomerated particles of the present invention have beneficial properties including high BET surface area and uniform porosity with a minimal proportion of closed and ...

Embodiment 1

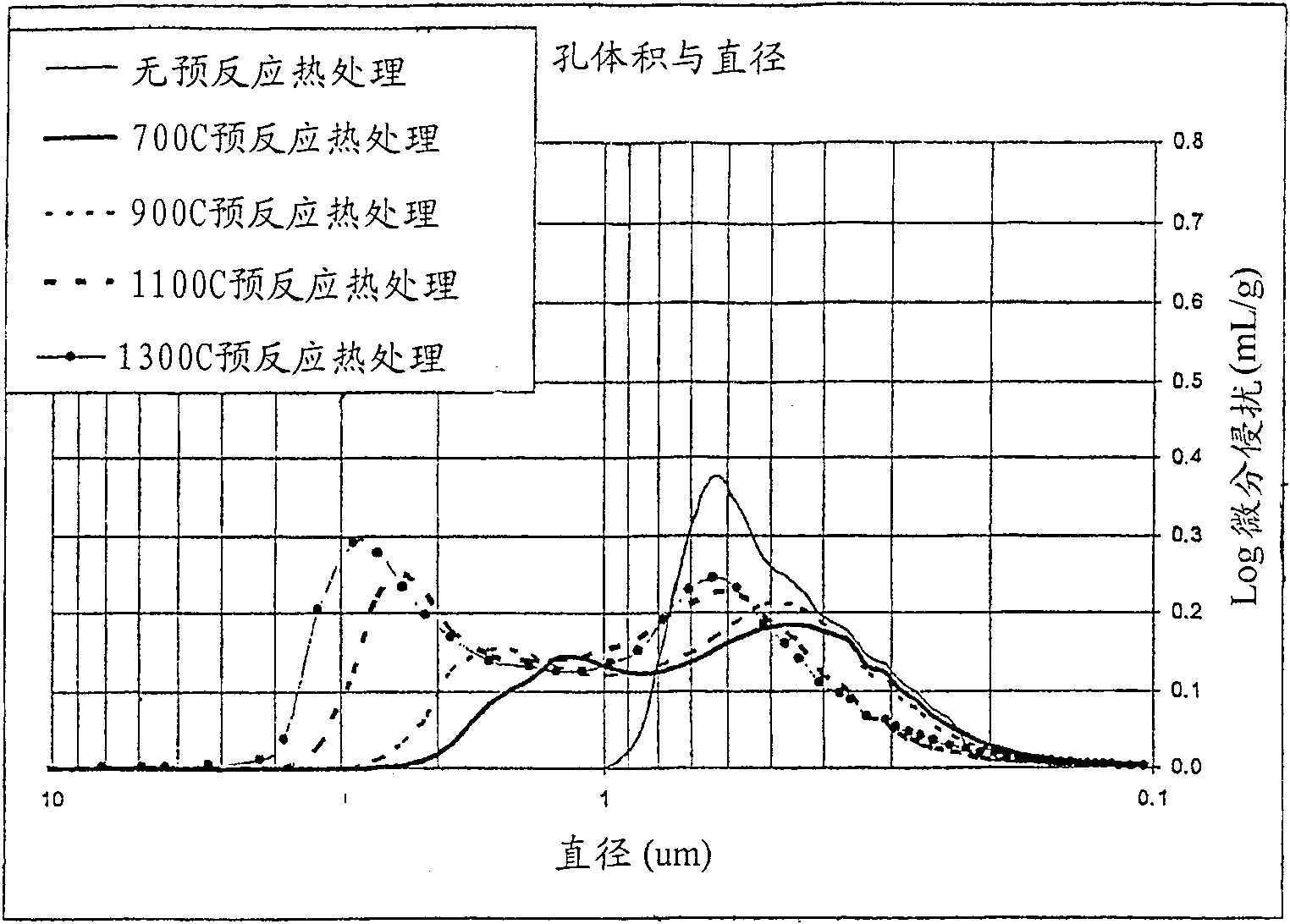

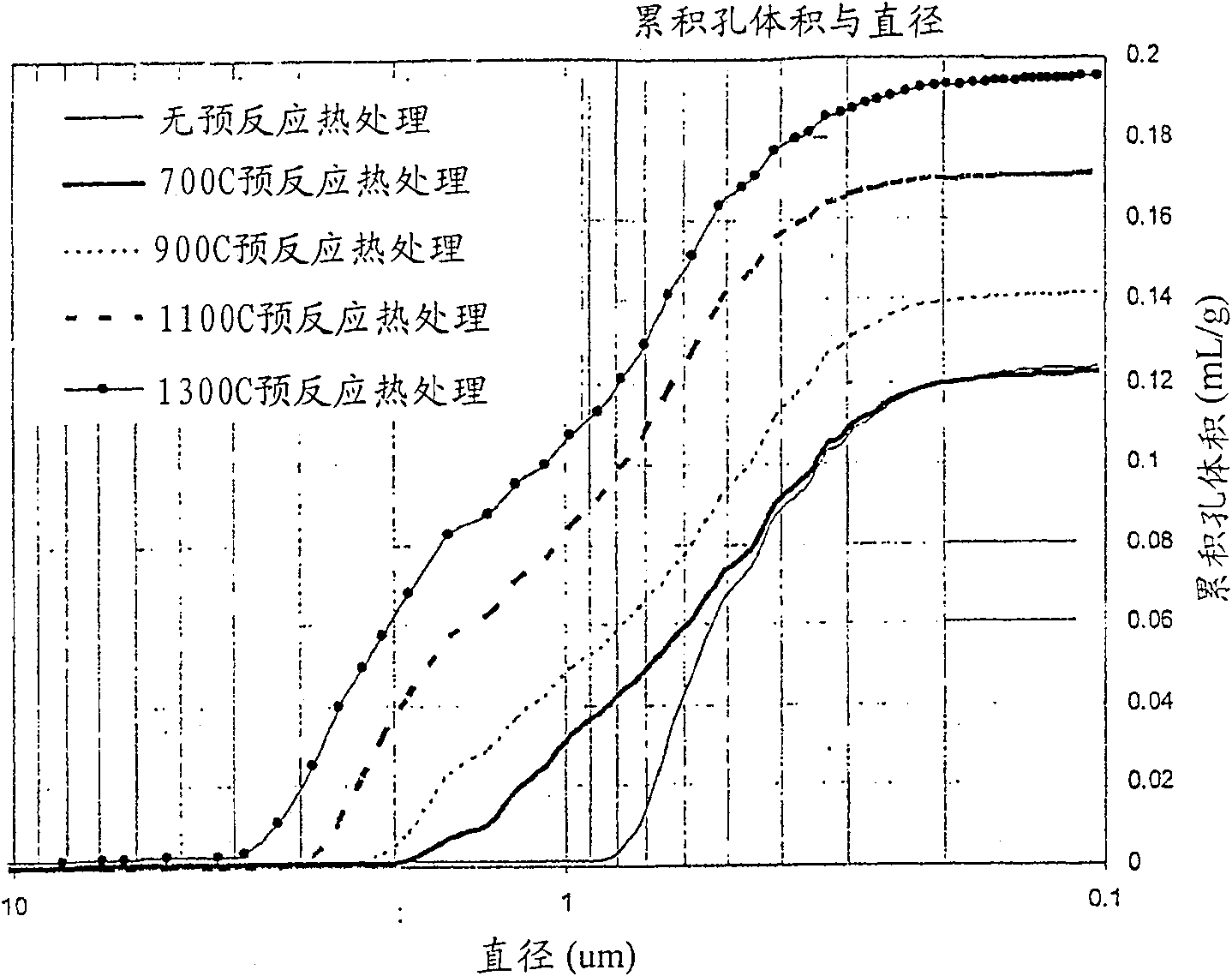

[0236] According to one embodiment of the invention, there will be a BET surface area of 4.1 m 2 / g of niobium powder (200g) and starting niobium oxide (161g), i.e. with a BET surface area of 1.3m 2 / g of niobium pentoxide are mixed together to form a powder mixture. The powder mixture was then granulated and sieved to a particle size of about -40 mesh. The pellet powder mixture was placed in a vacuum heat treatment furnace and heated to about 700° C. under vacuum for about 2 hours. Hydrogen was then passed into the furnace to a pressure of about 960 Torr. The temperature in the furnace was then changed to about 850°C and held for about 1 hour. After forming, various properties of the oxygen-reduced niobium oxides were tested and listed in Table 1. Three or more tests were performed on three or more sample batches of niobium powder and starting niobium oxide, wherein the above tests were repeated with heat treatment temperatures of 900, 1,100, and 1,300°C, respectively...

Embodiment 2

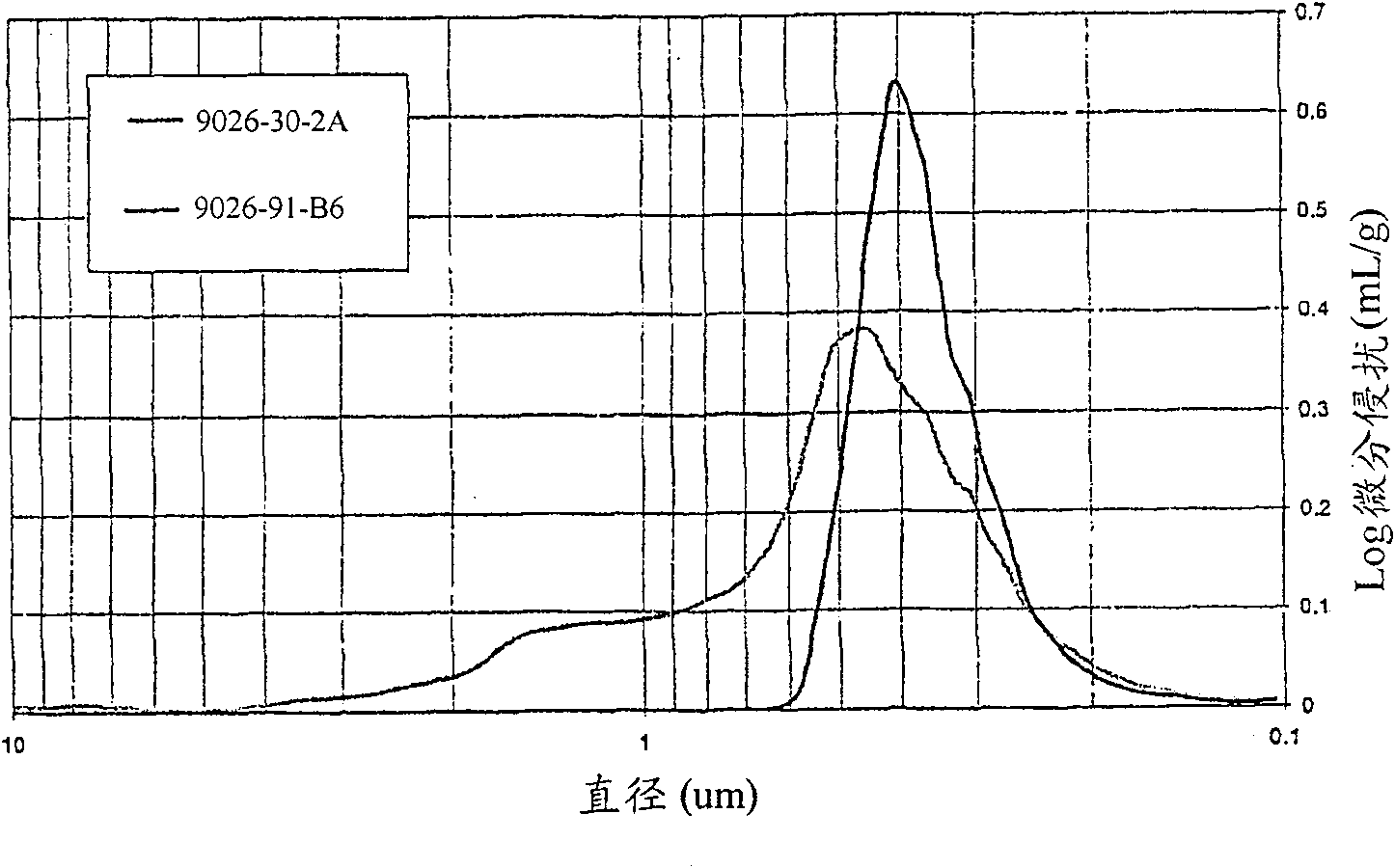

[0244] According to one embodiment of the invention, will have a BET surface area of 3.9m 2 / g of niobium powder (20g) and starting niobium oxide (16.1g), which has a BET surface area of 3.9m 2 / g of niobium pentoxide are mixed together to form a powder mixture. The powder mixture was then attritor milled (co-milled) in water with 3 / 16" Nb media for 2 hours. The powder slurry was vacuum dried at 120°C and passed through the dried powder through a 50 mesh sieve The granule powder mixture is put into a vacuum heat treatment furnace and heated to about 1100° C. for about 2 hours. Then the temperature in the furnace is changed to about 850° C. and hydrogen is passed into the furnace to pressure About 960 torr, held for about 1 hour. After forming, the various properties of the niobium oxide of oxygen reduction were tested and listed in Table 2. In addition, sample batches of niobium hydride and niobium pentoxide were tested as described above in the absence of Mix under attr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com