Method for wastewater treatment and circulation recover zero discharge in lipoic acid preparation

A recycling and wastewater treatment technology, applied in water/sewage treatment, natural water treatment, multi-stage water/sewage treatment, etc., can solve the problems of increased treatment costs, waste of water resources, high treatment costs, etc., to reduce concentration Quantity of purification treatment, zero discharge of water resources, and the effect of reducing external discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

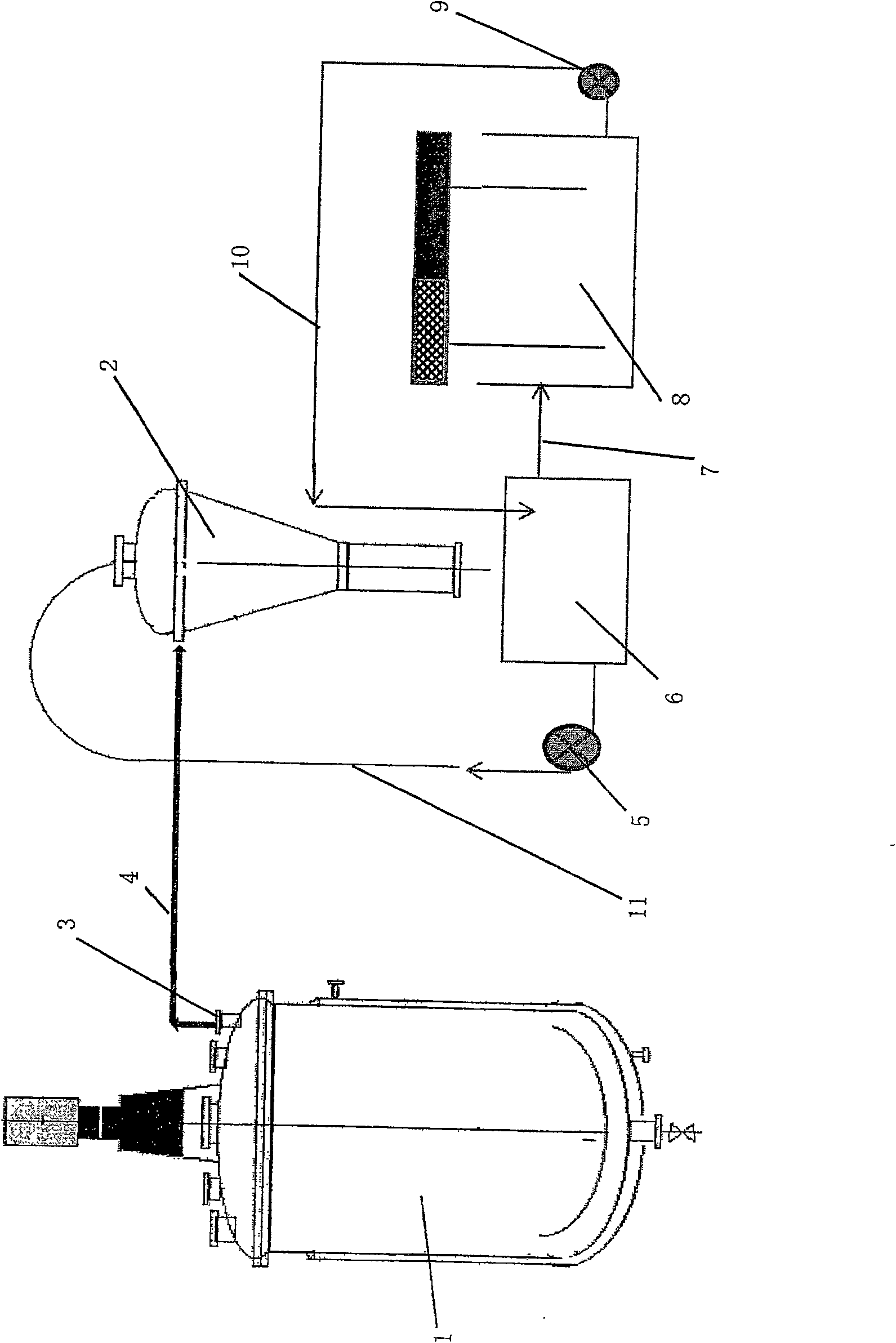

[0023] please see figure 1 , the applicant combined this figure to explain the principle of clear and turbid flow of circulating water in water flushing pumps, as known in the industry, in various process steps of lipoic acid production, such as esterification, acylation, addition, reduction and chlorination, etc. are equipped with figure 1 The corresponding water flushing pump 2 shown is used to evacuate the corresponding reactor 1 . The principle of vacuumizing the reaction kettle 1 in the above-mentioned processes is the same, so the applicant only uses the water flushing pump 2 of the vacuumizing of the reaction kettle 1 in the esterification process in the present embodiment. The reuse of circulating water will be explained. Based on the principle of inferring other cases from one instance or referring to analogy by analogy, the applicant does not repeat the description of the recycling of the water flushing pump circulating water in the process links such as esterifica...

Embodiment 2

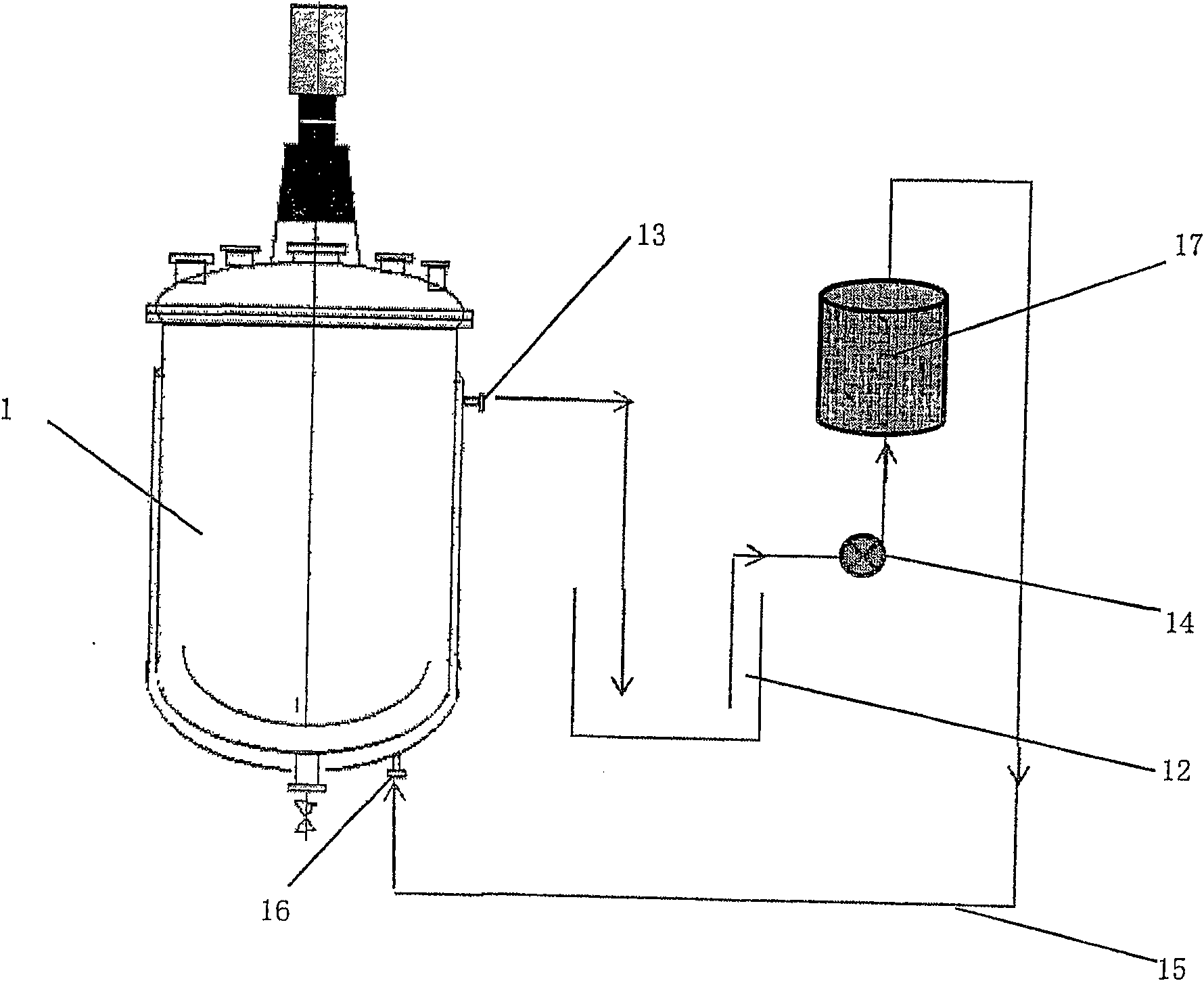

[0027] please see figure 2 , the applicant combined this figure to explain the principle of turbidity separation of circulating cooling water, still aiming at the esterification reaction. During the esterification reaction process of the reactor 1, the jacket cooling of the reactor 1 is required, so a centralized cooling water pool 12 is built in the production area or the factory area, and the water is introduced into the cooling water outlet 13 of the jacket of the reactor 1. Cool in the cooling water pool 12, and introduce the cooling water inlet 16 of the jacket of the reactor 1 by the third circulation pump 14 through the fourth introduction pipe 15, forming a cooling water circulation loop. The above-mentioned cooling water circulation loop shows natural cooling, that is, it is naturally cooled to normal temperature in the cooling water pool 12, but when the summer temperature is high, the cooling tower 17 can be activated, so a cooling tower is provided on the pipeline...

Embodiment 3

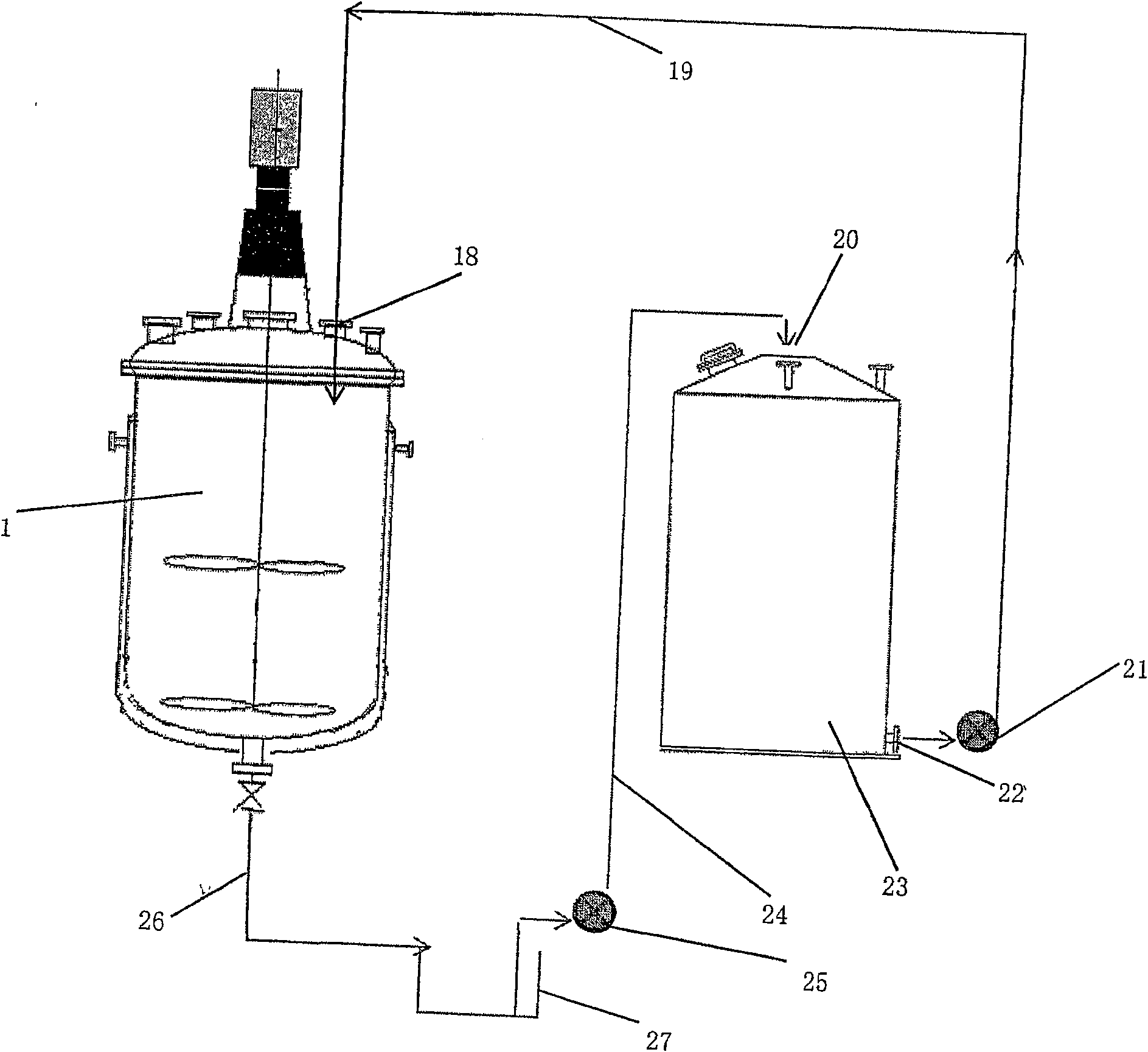

[0030] please see image 3 , the applicant combined this figure to explain the principle of recycling water containing the same organic material in the same process link, and continued to take the esterification reaction as an example. The water for feeding that is drawn from the water storage tank water outlet 22 of the water storage tank 23 is introduced into the reactor 1 from the feed water outlet 18 of the reactor 1 through the fourth circulation pump 21 on the pipeline of the fifth guide pipe 19, and is then connected to the outlet of the reactor. The sixth guide pipe 26 on the water port is introduced into the process water pool 27, and then the water in the process water pool 27 is introduced into the water storage tank 23 through the water storage tank inlet 20 of the water storage tank 23 by the fifth circulation pump 25 through the seventh guide pipe 24 , forming a water circulation loop, that is, forming the same process for recycling. Since the water drawn from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com