Vertically delicate adjusting and gravity force compensating mechanism and photo-etching machine

A technology of gravity compensation and lithography machine, which is applied in the direction of micro-lithography exposure equipment, photolithography exposure device, etc., and can solve the problems of disordered vibration of lithography system and great influence of lithography system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The vertical fine-tuning and gravity compensation device, the micro-movement table, and the photolithography machine of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

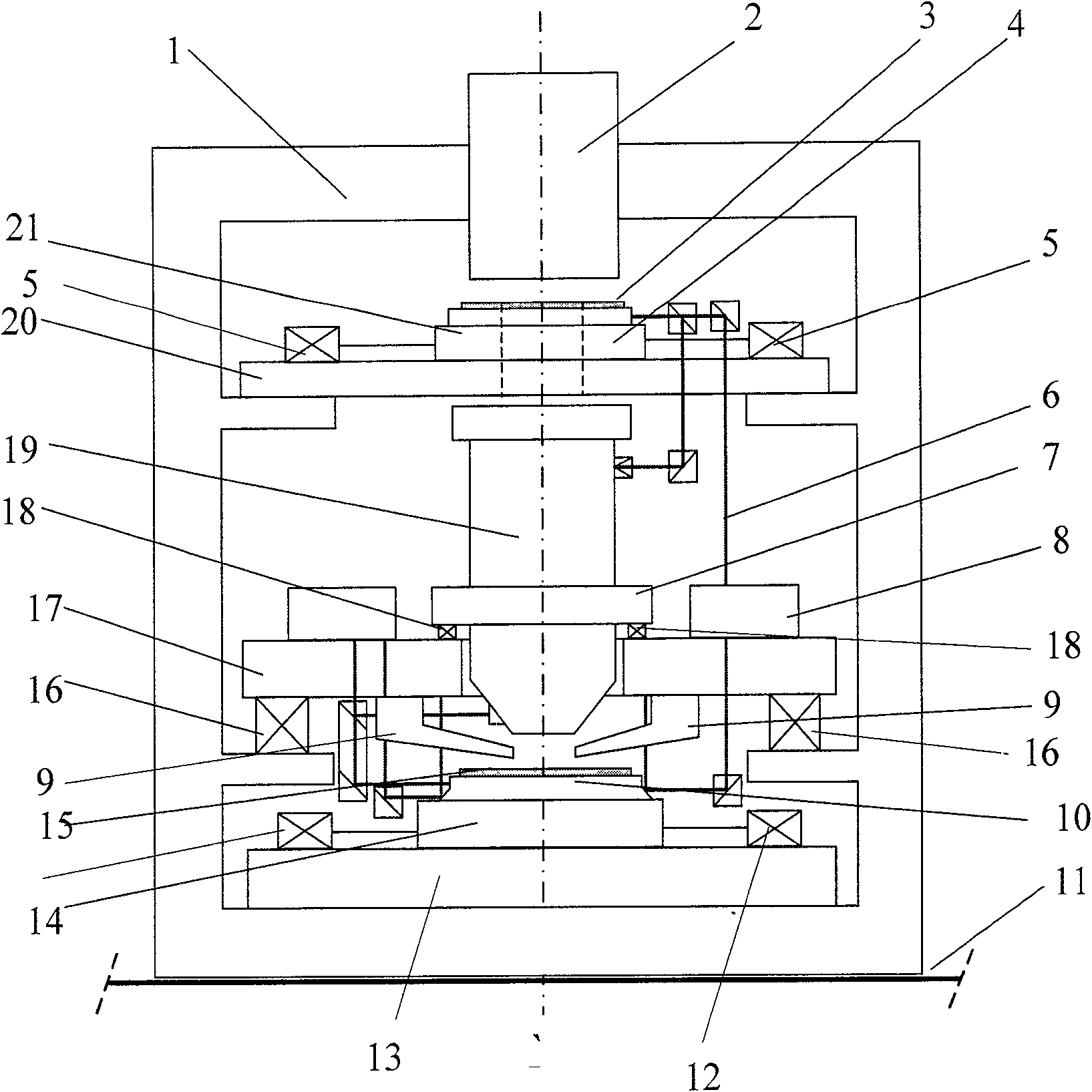

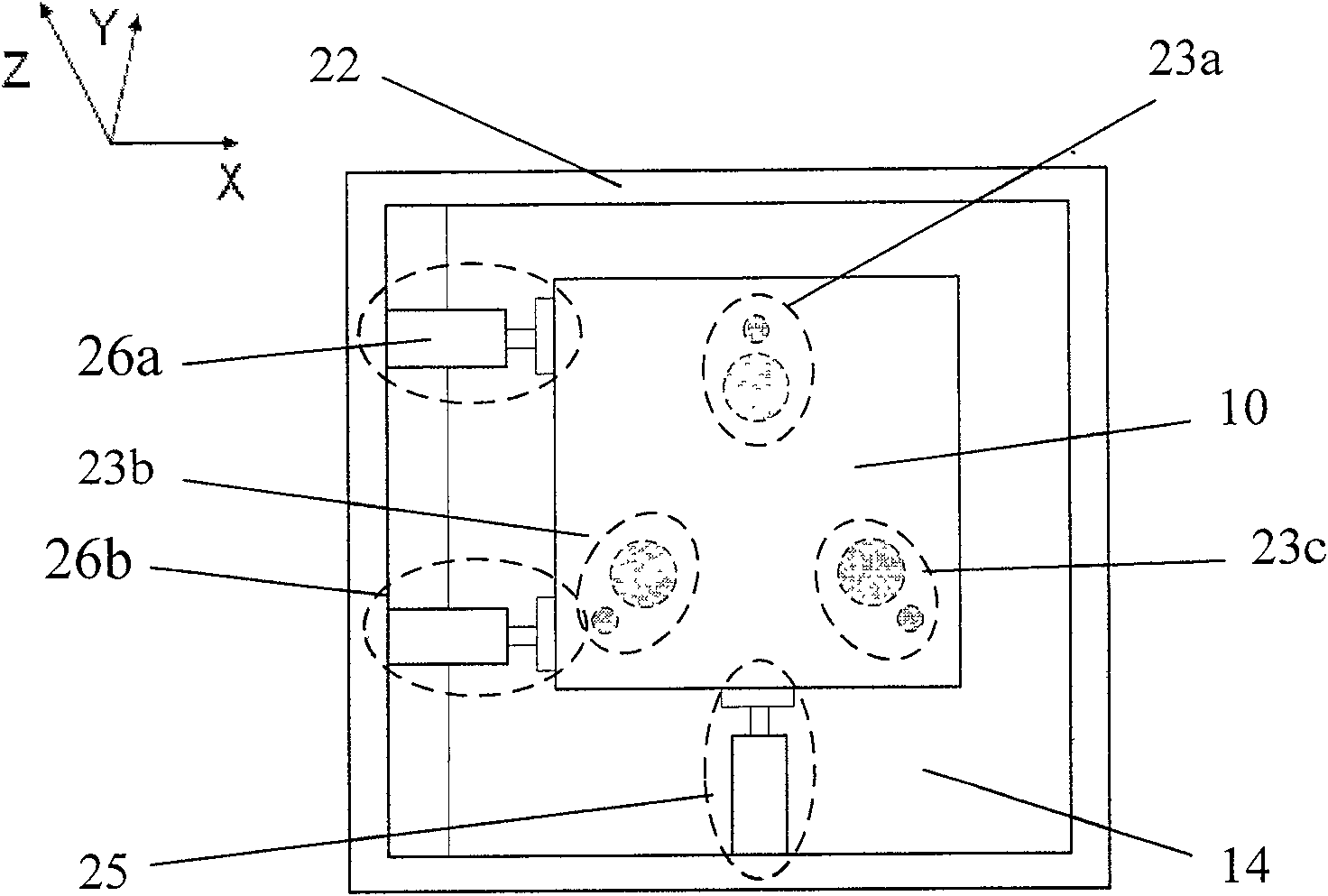

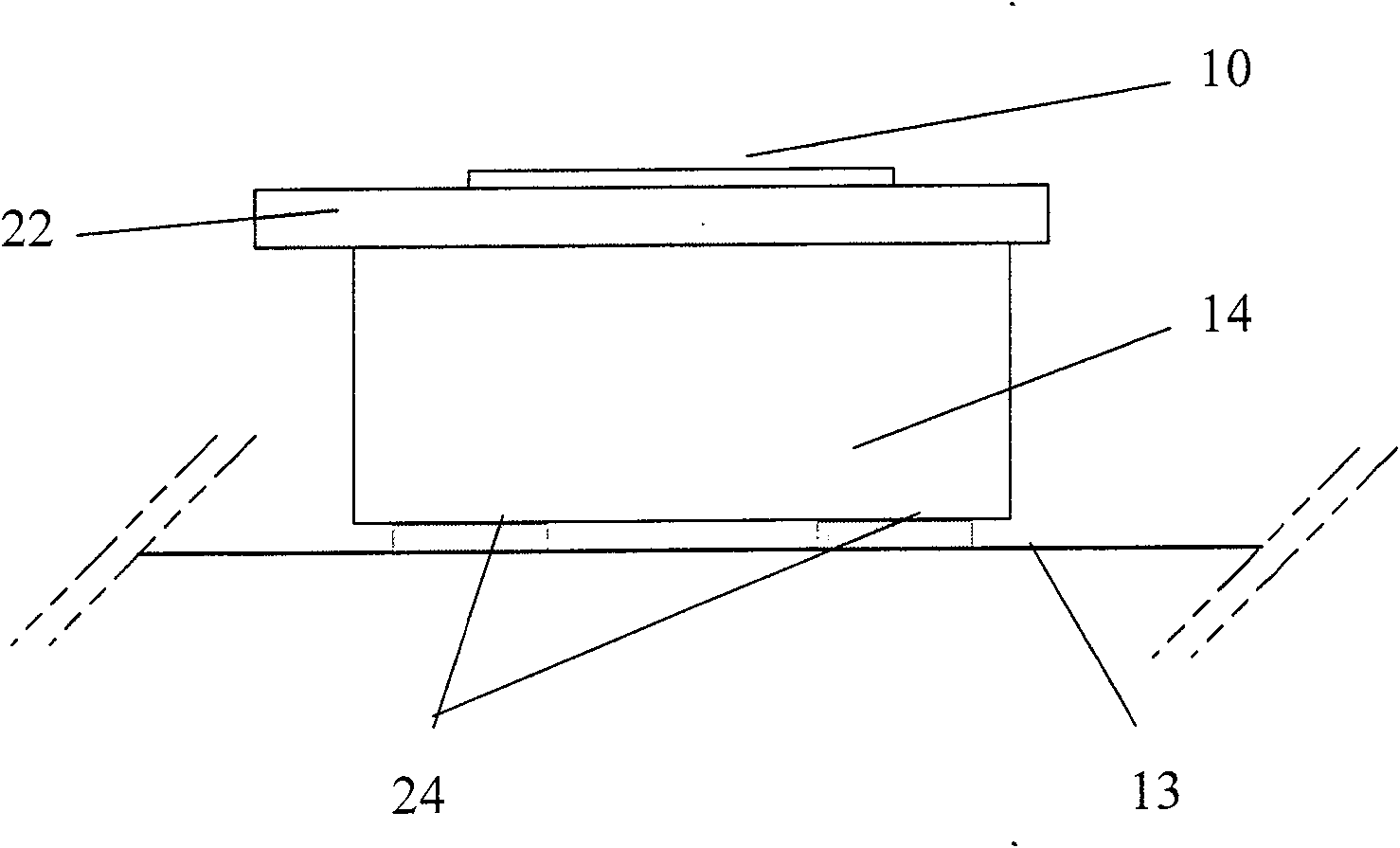

[0038] figure 1It is an overall structural diagram of a high-precision lithography machine of the present invention, which belongs to a high-precision step-and-scan lithography machine, and mainly includes an illumination system, a mask table system, a projection objective lens, an alignment measurement system, and a workpiece table system. They are all directly or indirectly installed on the base frame 1 . Wherein, the lighting system 2 , the mask table system and the workpiece table system are directly installed on the base frame 1 . The mask stage system mainly includes a reticle 3 , a long-stroke base 4 , a mask stage long-stroke motor 5 , a balance mass 20 , and a mask stage carrying micro-motion stage 21 on the balance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com