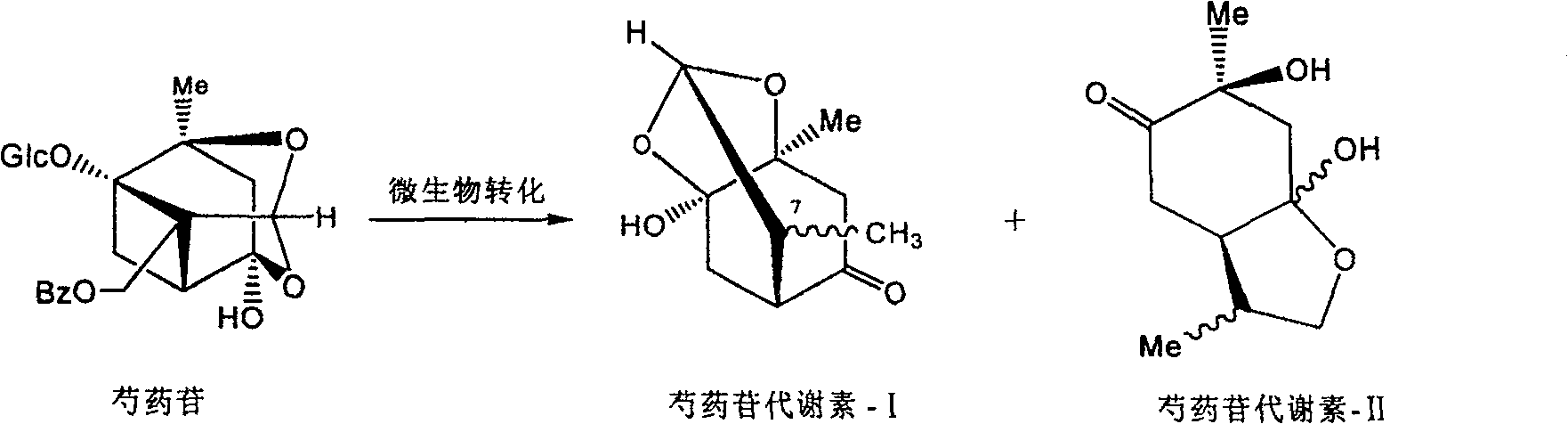

Method for producing paeonin metabolite-I by short lactobacillin fermentation

A technology of paeoniflorin metabolites and Lactobacillus brevis, which is applied in the field of biochemical engineering, can solve the problems of unsuitability for industrialization, no report of yield rate, long conversion time, etc., and achieve easy control of the process, mature separation method, and fast production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

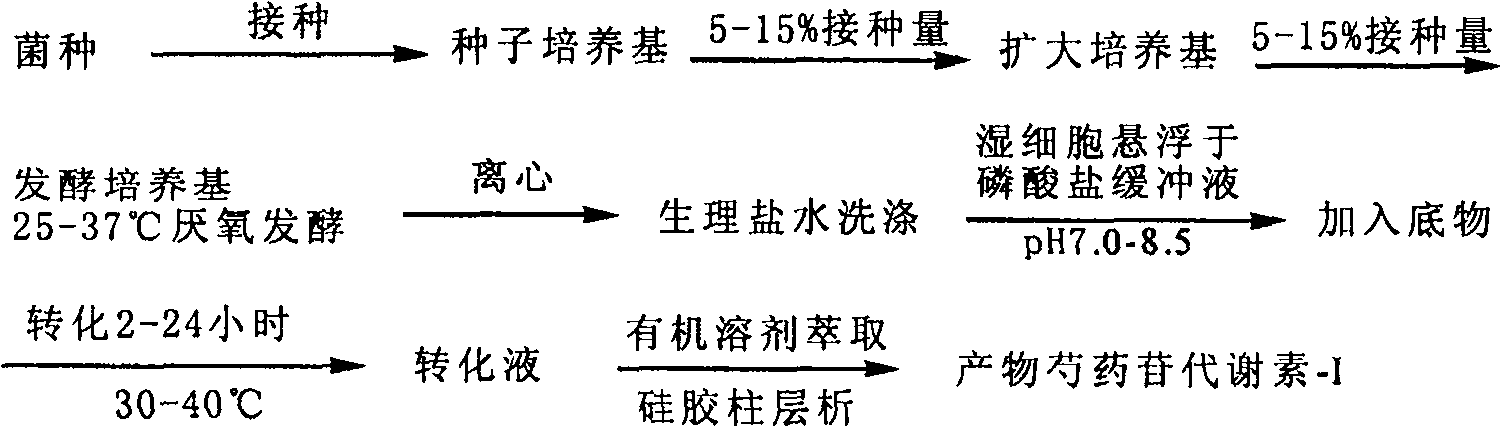

Method used

Image

Examples

Embodiment 1

[0026] The components and contents of seed medium, expansion medium and fermentation medium are: tomato juice 200g / L, peptone 7.5g / L, yeast extract 7.5g / L, glucose 10g / L, Tween 80 0.3ml / L L, adjust the pH value to 7.0-8.5 with 10% NaOH, and sterilize at 115°C for 30 minutes.

[0027] Take out 10ml of Lactobacillus brevis AS 1.12 from the anaerobic tube, inoculate it into 100ml of seed medium, and culture it anaerobically at 37°C for 24 hours, and culture 5 copies in total. Inoculate 5 parts of the culture solution into 5L expansion medium, expand the culture for 24 hours, inoculate the culture solution into 45L fermentation medium, culture anaerobically at 37°C for 24 hours, collect the cells by centrifugation, wash once with normal saline, and inoculate Suspend in 0.05 mol / L phosphate buffer (concentration: 40 g wet cells / L) and add paeoniflorin to make the concentration 1 mg / ml, transform at 37° C. for 6 hours. The conversion solution was extracted 4 times with ethyl acetat...

Embodiment 2

[0029] The components and contents of seed culture medium, expansion medium and fermentation medium are the same as in Example 1.

[0030] Take out 10ml of Lactobacillus brevis AS 1.12 from the anaerobic tube, inoculate it into 100ml of seed medium, and culture it anaerobically at 37°C for 24 hours. Inoculate the culture solution in 1L expansion medium, expand the culture for 24 hours, inoculate the culture solution in 10L fermentation medium, culture anaerobically at 37°C for 24 hours, collect the cells by centrifugation, wash once with normal saline, and suspend in Add benzoyl paeoniflorin to 0.05 mol / L phosphate buffer solution (concentration: 40 g wet cells / L) to make the concentration 1 mg / ml, and transform at 37° C. for 6 hours. The conversion solution was extracted 4 times with ethyl acetate, and the extracts were combined and concentrated to dryness to obtain 4.5 g of extract. The extract was subjected to ordinary silica gel column chromatography to obtain 0.1 g of pa...

Embodiment 3

[0032] The components and contents of seed culture medium, expansion medium and fermentation medium are the same as in Example 1.

[0033] Take out 10ml of Lactobacillus brevis AS 1.12 from the anaerobic tube, inoculate it into 100ml of seed medium, and culture it anaerobically at 37°C for 24 hours. Inoculate the culture solution in 1L expansion medium, expand the culture for 24 hours, inoculate the culture solution in 10L fermentation medium, culture anaerobically at 37°C for 24 hours, collect the cells by centrifugation, wash once with normal saline, and suspend in Add oxidized paeoniflorin to 0.05 mol / L phosphate buffer solution (concentration: 40 g wet cells / L) to make the concentration 1 mg / ml, and transform at 37° C. for 6 hours. The conversion solution was extracted 4 times with ethyl acetate, and the extracts were combined and concentrated to dryness to obtain 3.2 g of extract. The extract was subjected to ordinary silica gel column chromatography to obtain 0.07 g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com