MIG solder quality monitoring method based on electric arc multi-spectral coverage light information sensing

A quality monitoring and multi-spectral technology, which is applied in the process control field of gas shielded arc welding, can solve the problems of arc radiation spectral fluctuation, welding arc spectral fluctuation, and the sound signal is easily interfered, so as to optimize the signal quality and realize the Real-time monitoring, the effect of easy real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A typical MIG welding quality monitoring method based on arc multispectral optical information sensing is as follows: Figure 5 As shown, the welding power source is NB-500 gas shielded welding machine, which adopts flat characteristic matching and constant speed wire feeding to realize MIG welding. The trolley moves automatically during the welding process, protected by pure argon, and the welding wire is H08Mn2Si.

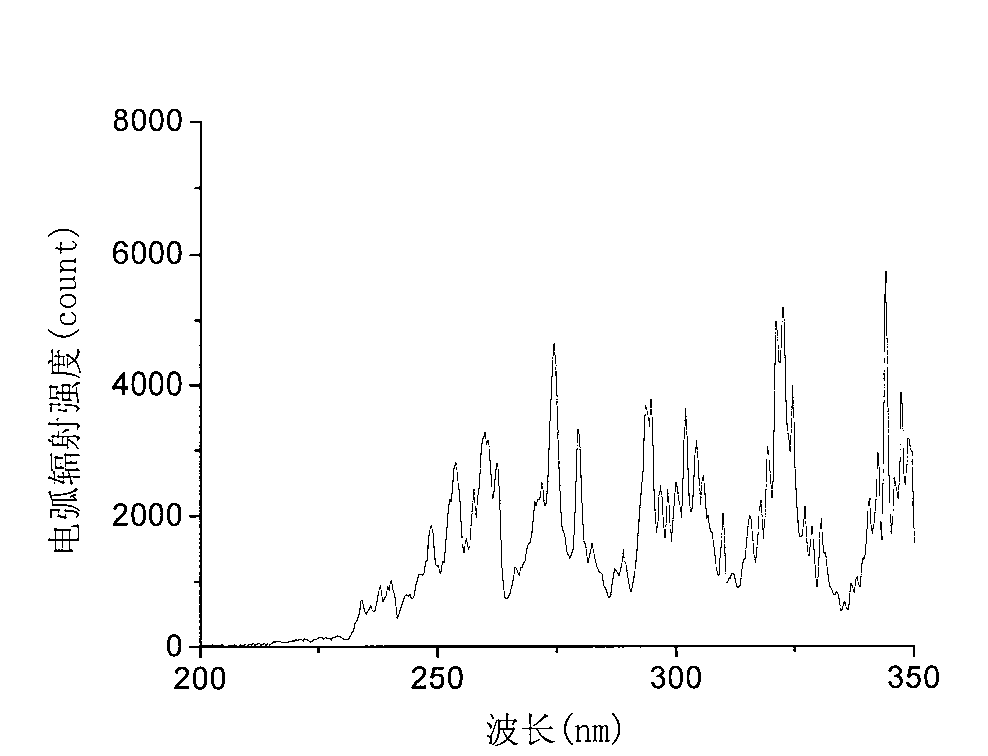

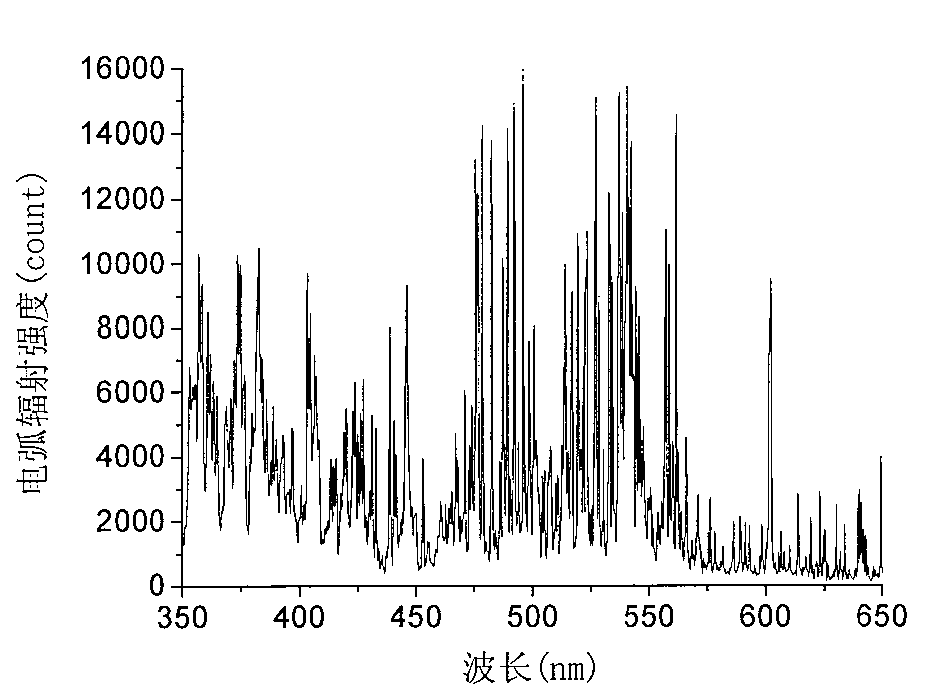

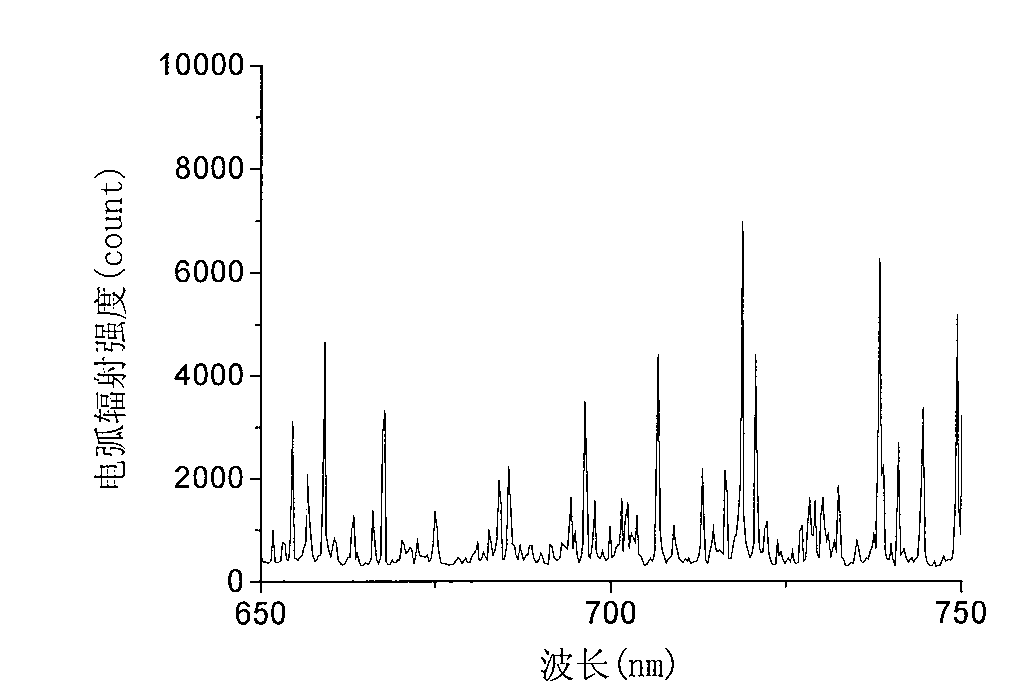

[0047] A "Y"-shaped optical fiber probe is used to collect the spectral radiation information emitted by the arc during the welding process at a fixed angle and distance, and transmit the radiation information to the spectrometer. ~590nm, 800~830nm four characteristic spectrum band spectral signal radiation integral intensity to collect, get the signal of spectral radiation intensity changing with time in the welding process, and realize photoelectric conversion through CCD, the collected spectral digital signal is passed through high-speed The USB2 interf...

Embodiment 2

[0051] exist Figure 8 During the welding process, due to external interference, the wire feeding speed increased from the normal value to the normal value. In the spectral signal of the 0.5Hz low-pass filter, it can be seen from the middle of different spectral bands that the wire feeding speed increases. The apparent reduction in radiation that occurred was followed by a return to the initial value when the wire feed speed returned to normal. The signal-to-noise in the F2 and F3 bands is the best. Comparing the signal in the F2 band with the standard radiation value (15000Counts) under this condition, the external interference signal that appears in the 10-25s band can be accurately detected.

Embodiment 3

[0053] Figure 9 During the welding process, the welding voltage changes under external interference, and the arc voltage drops twice (32-28V, 28-26V), which corresponds to the change of the 0.5Hz low-pass filter spectral signal, and the spectral segment with the best signal-to-noise ratio It is F2 and F3, the two voltage drops can find the corresponding signal characteristics at 14s and 24s respectively; comparing the radiation intensity value of the F2 spectrum with the standard radiation value (15000Counts), the interference signal that appears at 14s and 24s can be accurately detected .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com