Preparation process of sorbierite polyoxyethylene ether ester oleate

The technology of polyoxyethylene ether oleate and alcohol polyoxyethylene ether is applied in the field of preparation of ester compounds in organic chemistry, and the effects of mild reaction conditions, simple process and cost reduction are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Add 50 parts of sorbitol polyoxyethylene ether and 47 parts of oleic acid by weight in the reaction kettle, add 0.4 parts of p-toluenesulfonic acid catalyst under stirring, gradually heat up, and under vacuum state, the reaction conditions at a temperature of 170 ° C Under heat preservation for 8 hours, the temperature was lowered, and the yield was 96.5%.

Embodiment 2

[0016] Example 2: Add 50 parts of sorbitol polyoxyethylene ether and 28.2 parts of oleic acid by mass into the reaction kettle, add 0.3 parts of tributyl phosphate catalyst under stirring, gradually heat up, and react at a temperature of 180 °C under vacuum Under the condition of insulation for 3 hours, the temperature was lowered, and the yield was 96%.

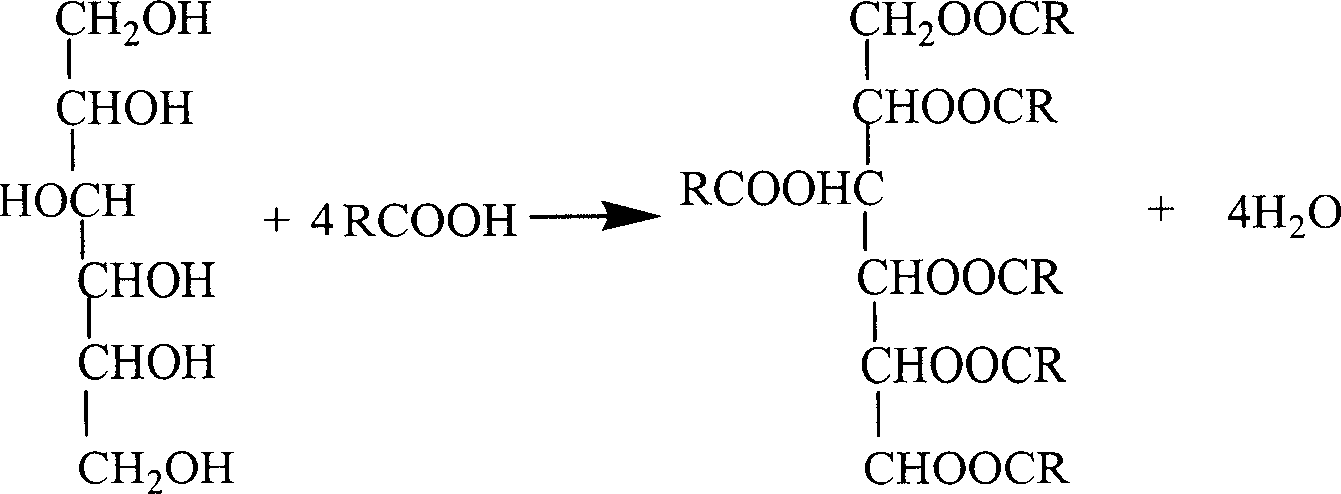

[0017] Its dehydration condensation reaction equation is in the above-mentioned embodiment:

[0018]

[0019] Note: RCOOH in the formula is oleic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com