Method for preparing metal and dielectric composite grains of silicon dioxide coated by Nano silver

A silicon dioxide and composite particle technology, applied in jewelry and other directions, can solve the problems of complicated operation steps, complex products, impurity, etc., and achieve the effect of high purity, no pollution, and mild method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

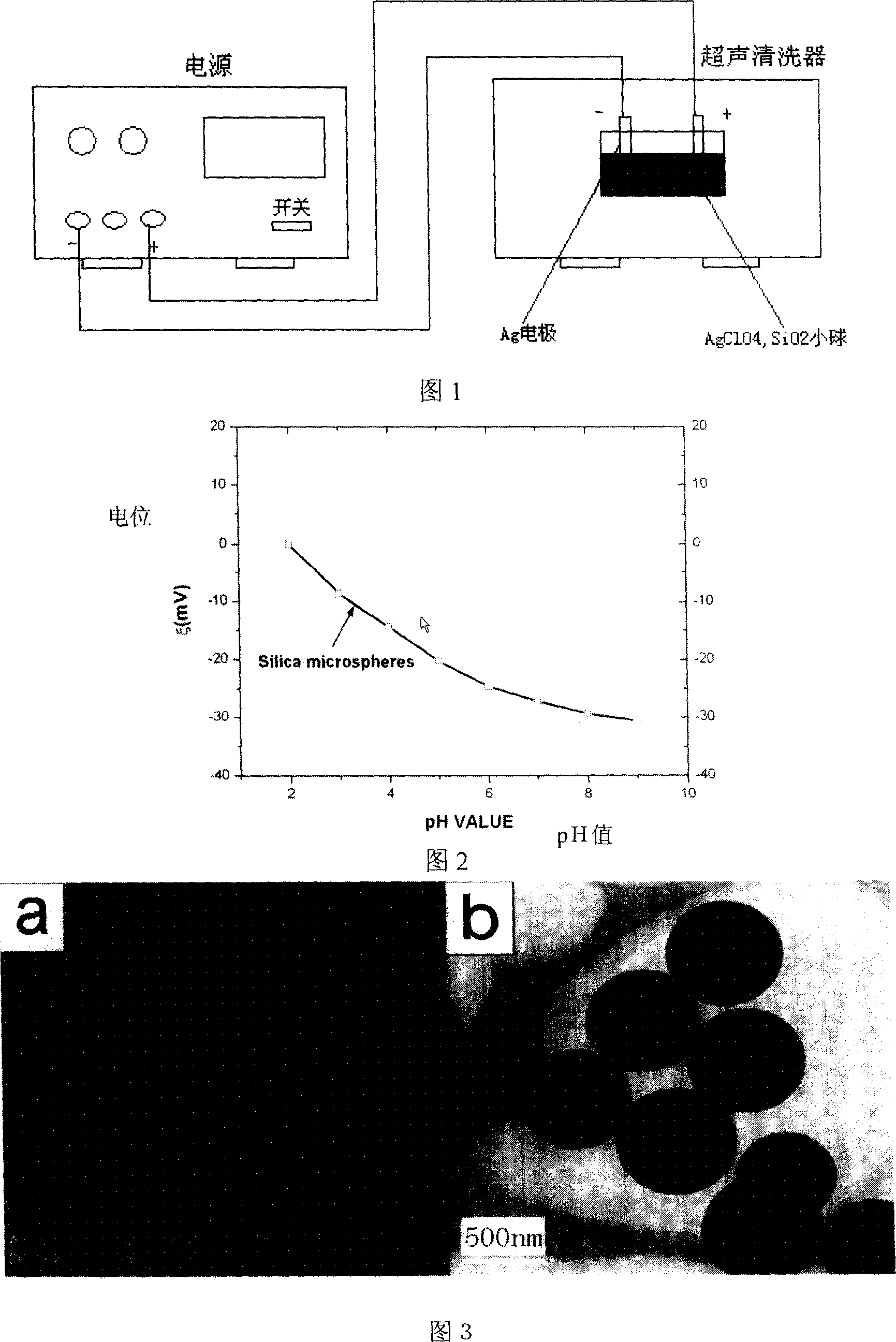

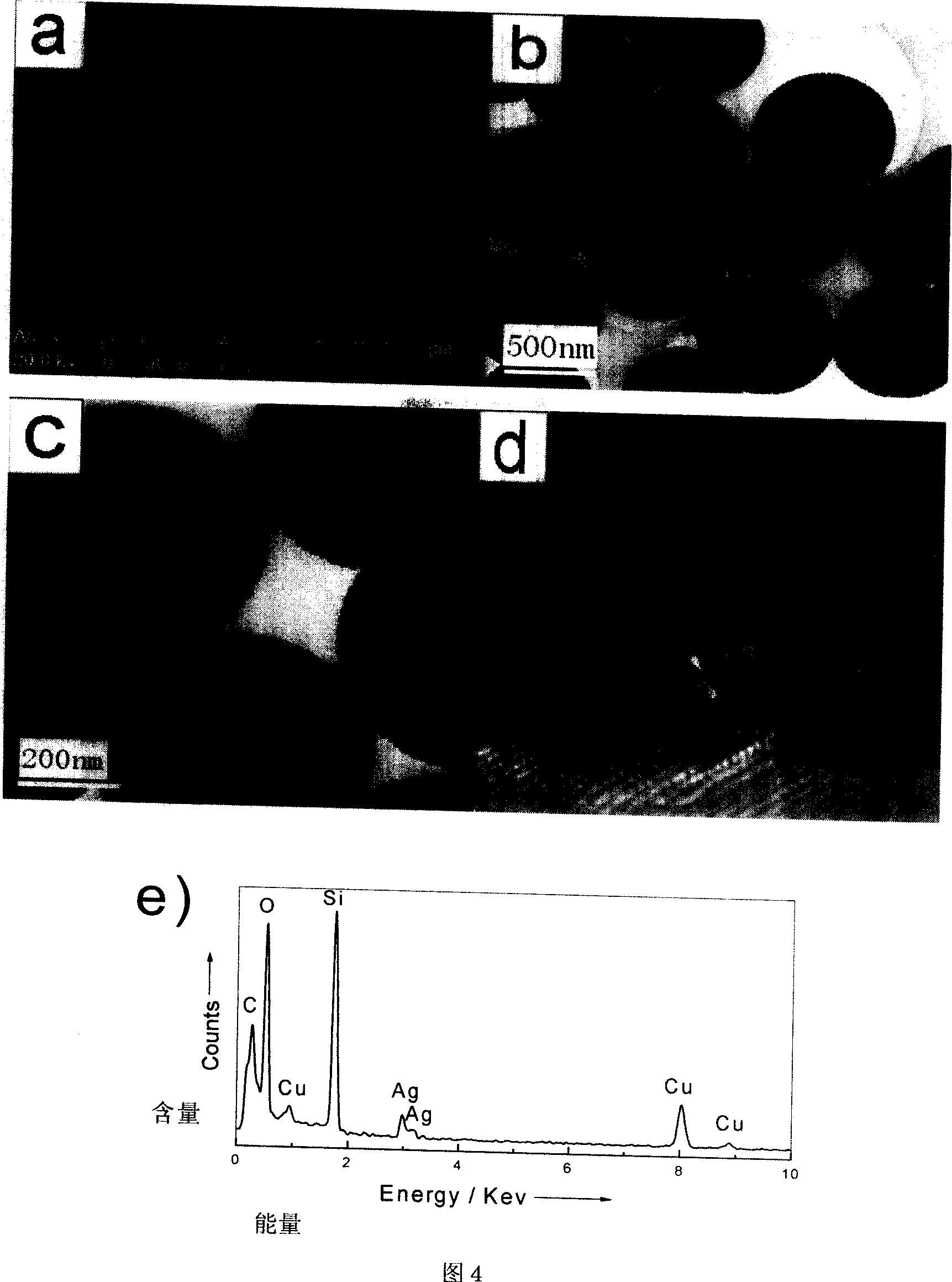

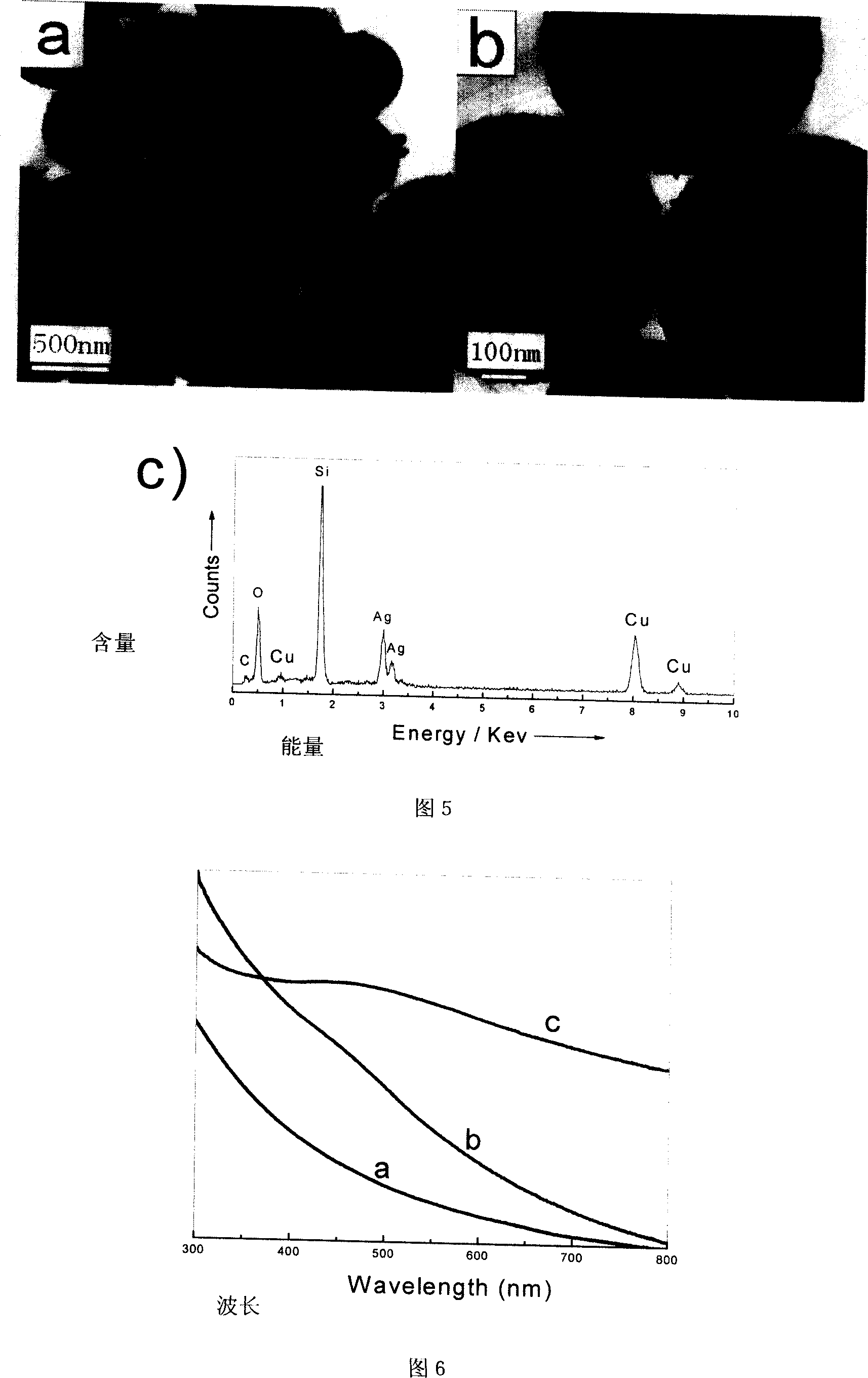

[0026] 1.SiO2 2 The synthesis process of submicron spheres: the specific experimental steps are: measure a certain volume of absolute ethanol and ammonia water (the mass fraction of ammonia gas in water is 25-28wt%) to make a mixed solution, pour it into an Erlenmeyer flask; Place the shaped flask on a magnetic stirrer, heat it in a water bath and control the temperature to 35-40°C; measure a certain volume of absolute ethanol and tetraethyl orthosilicate and make a mixed solution, stir it evenly and pour it into the dropping funnel: And in the case of vigorous magnetic stirring, drop the mixture of absolute ethanol and tetraethyl orthosilicate in the dropping funnel into the Erlenmeyer flask drop by drop; after the addition, continue to stir slowly at constant temperature for 24 hours; 5. Finally, Use ethanol and deionized water to carry out centrifugation-dispersion washing-centrifugation on the resultant, and repeat 4-5 times. After removing impurities, the centrifuged sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com