Fine particulate titanium dioxide, and production process and use thereof

A titanium dioxide and particle technology, applied in titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve problems such as affecting water or hydroxyl groups, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

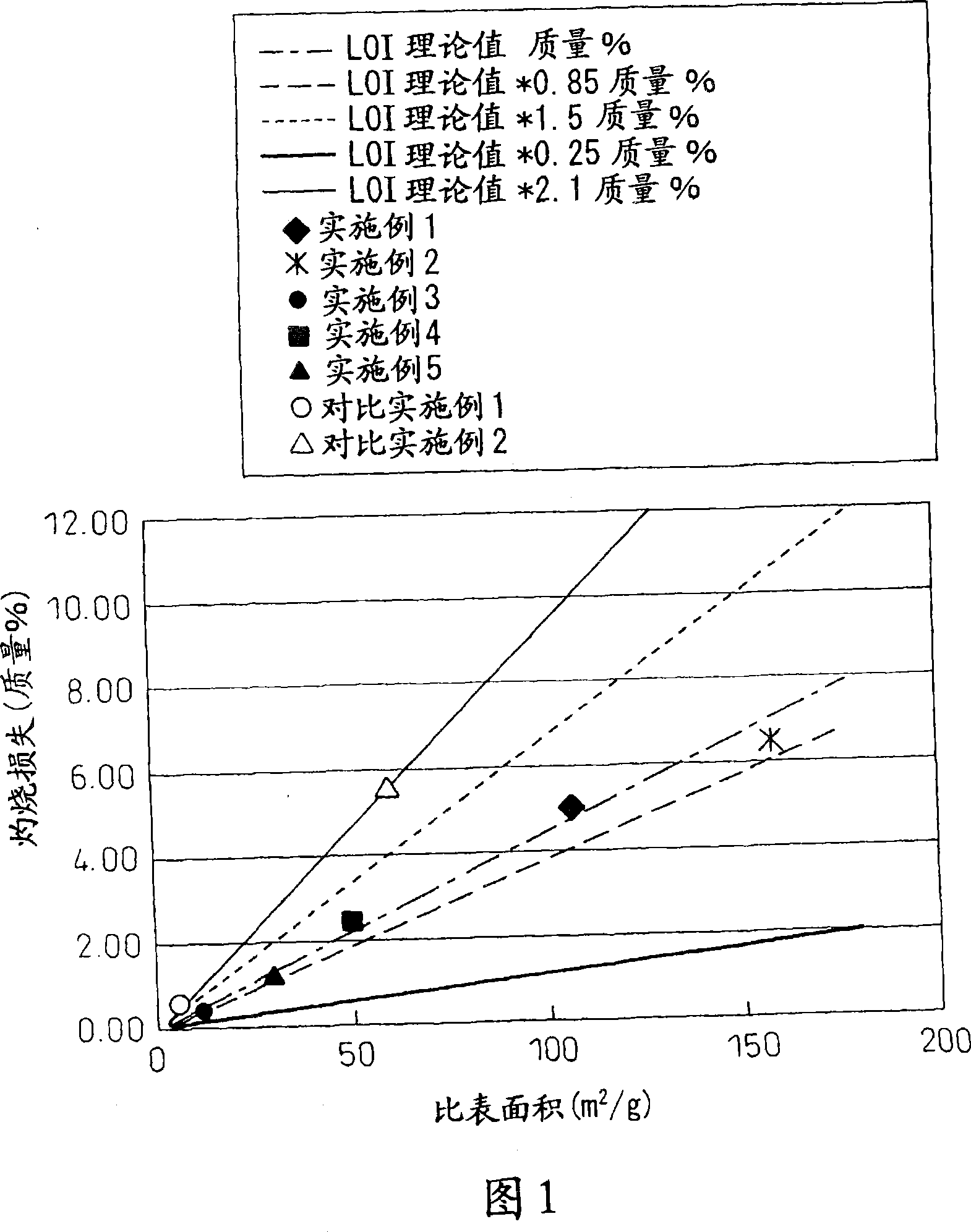

Image

Examples

Embodiment 1

[0138] Will use 25Nm 3 Titanium tetrachloride 20 kg / hr diluted with nitrogen gas / hr (N refers to the standard state in which the state is converted to an ideal gas, the same below) was preheated to 1,100° C. and fed into the reaction tube. Similarly, the 55Nm 3 The water vapor per hour was heated to 1,100° C. and supplied into the reaction tube to react with the titanium tetrachloride gas to obtain fine particle titanium dioxide. These particles were collected in a polytetrafluoroethylene bag filter and then fed into an externally heated rotary kiln. The externally heated rotary kiln has a structure in which stirring blades for stirring the powder are assembled inside. The rotary kiln was set to a temperature of 400° C., and the residence time of the powder body was adjusted to about 1 hour by controlling the length of the high temperature zone, the rotation speed and the angle at which the rotary kiln was installed.

[0139] Separately, water vapor in an amount of 20% by...

Embodiment 2

[0146] Will use 25Nm 3 5 kg / hr of titanium tetrachloride diluted with nitrogen gas per hr was preheated to 1,100°C and fed into the reaction tube. Similarly, the 55Nm 3 The water vapor per hour was heated to 1,100° C. and supplied into the reaction tube to react with the titanium tetrachloride gas to obtain fine particle titanium dioxide. These particles were collected by a polytetrafluoroethylene bag filter and then fed into an externally heated rotary kiln. The externally heated rotary kiln has a structure in which stirring blades for stirring the powder are assembled inside. The rotary kiln was set to a temperature of 400° C., and the residence time of the powder body was adjusted to about 1 hour by controlling the length of the high temperature zone, the rotation speed and the angle at which the rotary kiln was installed.

[0147] Separately, water vapor in an amount of 30% by mass based on the mass of titanium dioxide passing through the rotary kiln was fed into the ro...

Embodiment 3

[0154] 150 kg / hr of titanium tetrachloride was preheated to 900°C and fed into the reaction tube. Similarly, the 30Nm 3 The water vapor per hour was heated to 900° C. and fed into the reaction tube to react with the titanium tetrachloride gas to obtain fine particles of titanium dioxide. These particles were collected by a polytetrafluoroethylene bag filter and then fed into an externally heated rotary kiln. The externally heated rotary kiln has a structure in which stirring blades for stirring the powder are assembled inside. The rotary kiln was set to a temperature of 400° C., and the residence time of the powder body was adjusted to about 45 minutes by controlling the length of the high temperature zone, the rotation speed and the angle at which the rotary kiln was installed.

[0155] Separately, water vapor in an amount of 3% by mass based on the mass of titanium dioxide passing through the rotary kiln was fed into the rotary kiln from the outlet of the powder body, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com