Biological antistain agent with low surface energy characteristic and its preparing process

A biological antifouling agent, low surface energy technology, applied in the fields of botanical equipment and methods, chemicals for biological control, biocides, etc., can solve practical difficulties, low surface energy and other problems, and achieve strong growth inhibition effect , The effect of improving antifouling performance and good application development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

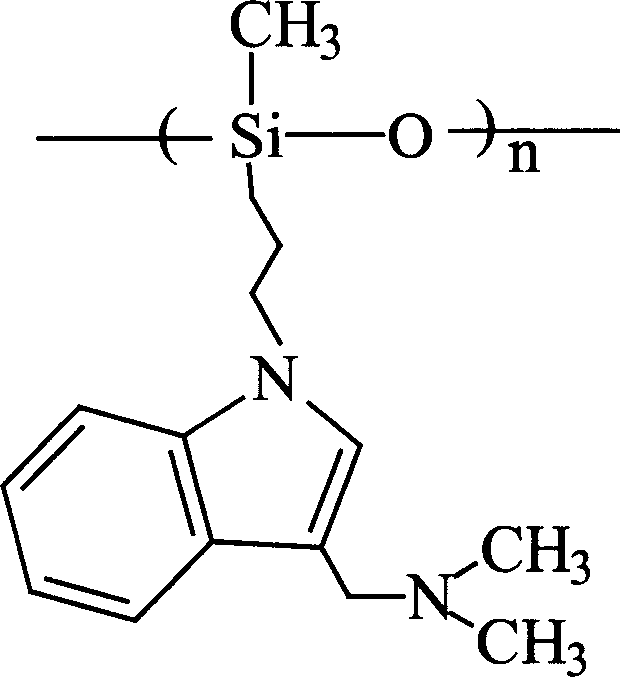

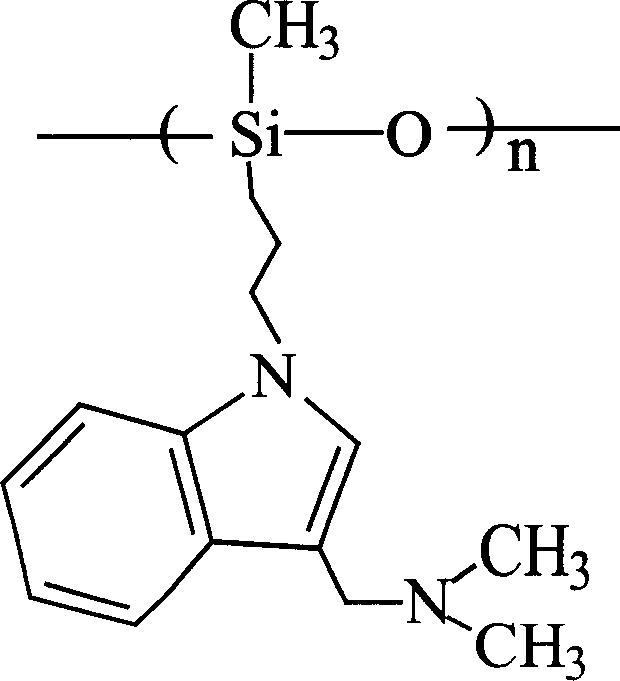

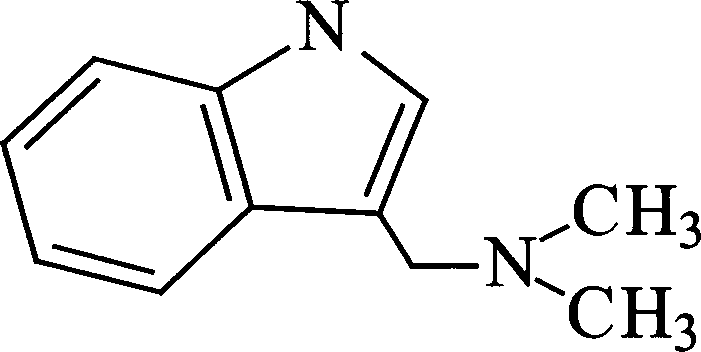

[0025] First, put 40mmol of the alkaloid 3-dimethylaminomethylindole into the reaction vessel, then add 20mmol of potassium hydroxide, and slowly drop in 60mmol of 3-chloropropene under stirring condition to form N,N-dimethyl Formamide is used as a solvent. After the reaction is completed, the reaction mixture is added to water, and then extracted with chloroform. After the extract is dried, the chloroform is removed by vacuum filtration, and the N-allyl 3- Alkaloid derivatives of the dimethylaminomethylindole structure.

[0026] Then, add 3.0 mmol of hydrogen-containing silicone oil, 10.0 mmol of alkaloid derivatives, and 6.0 ml of anhydrous toluene into a reaction vessel equipped with a stirring magnet, and mix well.

[0027] The third step is to add a small amount of dichlorodicyclopentadiene platinum as a catalyst. Under the protection of argon, the temperature is controlled at 50 ° C, stirred, and reacted for 24 hours. After cooling, the solvent is evaporated under reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com