Rare earth multicomponent micro-alloying high-chromium cast iron and uses thereof

A technology of micro-alloying, high-chromium cast iron, applied in metal extrusion, metal rolling, metal rolling, etc., can solve the problems of high cost of imported equipment, inability to meet production needs, unsatisfactory wear resistance and service life, etc. , to achieve the effect of good machining performance, improved thermal fatigue life, wear resistance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

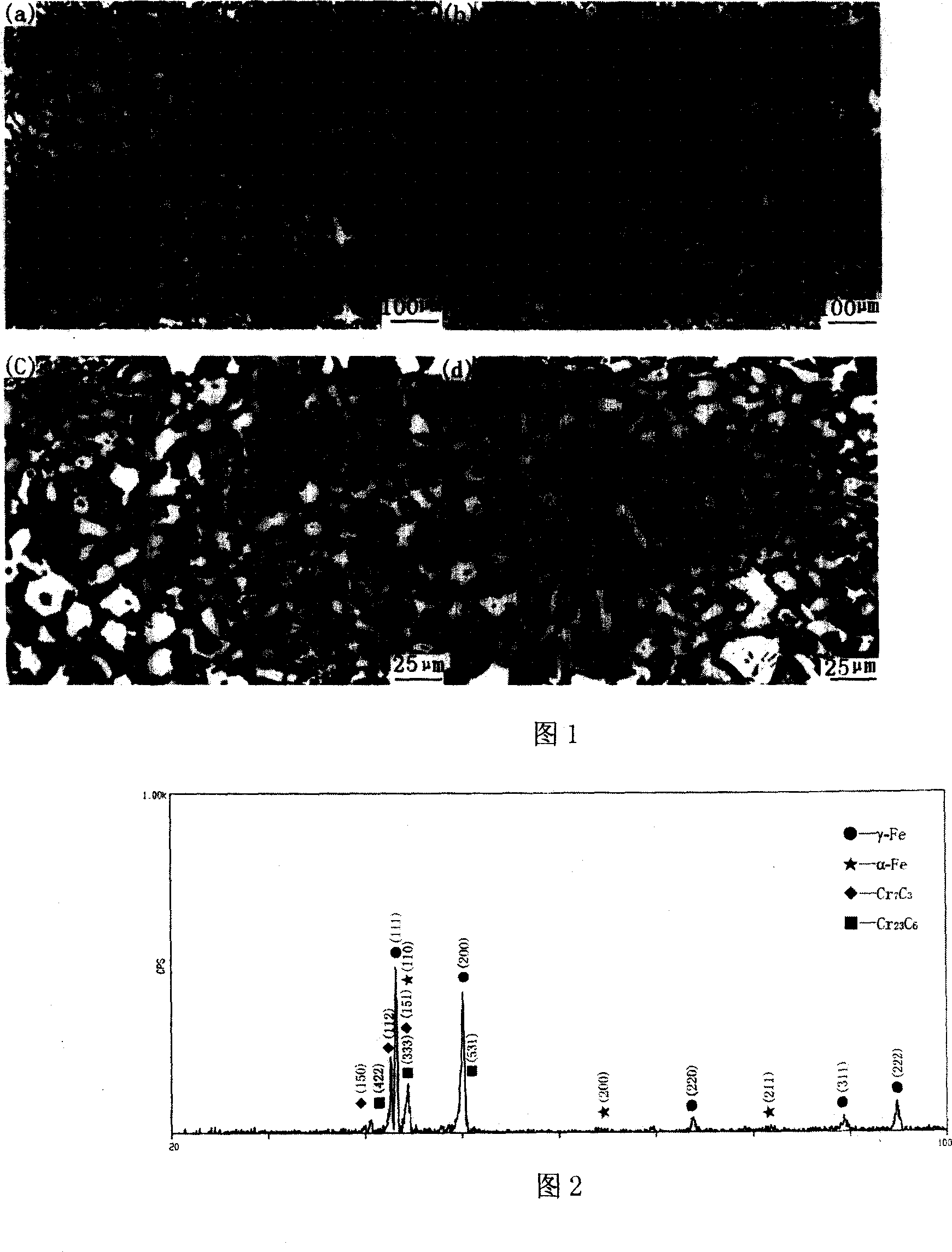

Image

Examples

Embodiment 1

[0047] The chemical composition of the cast iron contains 1.0-3.5 parts by weight of carbon, 8.0-26.0 parts of chromium, 0.5-4.5 parts of nickel, 0.15-2.0 parts of molybdenum, 0.5-2.0 parts of copper, 0.05-2.0 parts of aluminum, 0.05-2.0 parts of vanadium, 0.03-0.3 parts of rare earth and 0.005-0.20 parts of rare earth Silicon ≤ 0.5 part Manganese ≤ 0.7 part Sulfur ≤ 0.05 part Phosphorus ≤ 0.05 part The balance is iron.

Embodiment 2

[0049] The chemical composition of the cast iron contains by weight: 1.0-3.5 parts chromium 8.0-26.0 parts nickel 0.5-4.5 parts molybdenum 0.15-2.0 parts copper 0.5-2.0 parts aluminum 0.05-2.0 parts vanadium 0.03-0.30 parts titanium 0.03-0.30 parts Rare earth 0.005-0.200 parts Silicon: ≤0.5 parts Manganese: ≤0.7 parts Sulfur ≤0.05 parts Phosphorus ≤0.05 parts The balance is iron.

Embodiment 3

[0051] 1.0-3.5 parts chromium 8.0-26.0 parts nickel 0.5-4.5 parts molybdenum 0.1 5-2.0 parts copper 0.5-2.0 parts aluminum 0.05-2.0 parts vanadium 0.03-0.30 parts titanium 0.03-0.3 parts aluminum 0.05-2.0 parts rare earth 0.005-0.200 parts Silicon: ≤0.5 part Manganese: ≤0.7 part Sulfur ≤0.05 part Phosphorus ≤0.05 part The balance is iron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com