Centimeter grade plastic Cu-(Zr,Ti)-Al bulk amorphous alloy

An amorphous alloy, centimeter-level technology, which is applied in the field of Cu--Al bulk amorphous alloys, can solve problems restricting the application of amorphous metals, and achieve the effects of good plasticity, high hardness, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] This embodiment adopts suction casting method to prepare the Cu of diameter 6mm 45 Zr 46 al 7 Ti 2 Bulk amorphous alloys (amorphous alloys whose size reaches the order of millimeters are called bulk amorphous alloys).

[0017] Step 1: Put 99.95% pure Cu, 99.87% pure Zr, 99.5% pure Al and 99.98 pure Ti into Cu 45 Zr 46 al 7 Ti 2 The ratio is arc smelted in an argon atmosphere adsorbed by zirconium to obtain a uniformly mixed alloy ingot.

[0018] Step 2: Melt the ingot obtained in Step 1 on a water-cooled copper mold in an argon-protected melting furnace.

[0019] Step 3: inject the alloy liquid obtained in step 2 into a water-cooled copper mold with an inner diameter of 6 mm by using the pressure difference. A bulk amorphous alloy is produced.

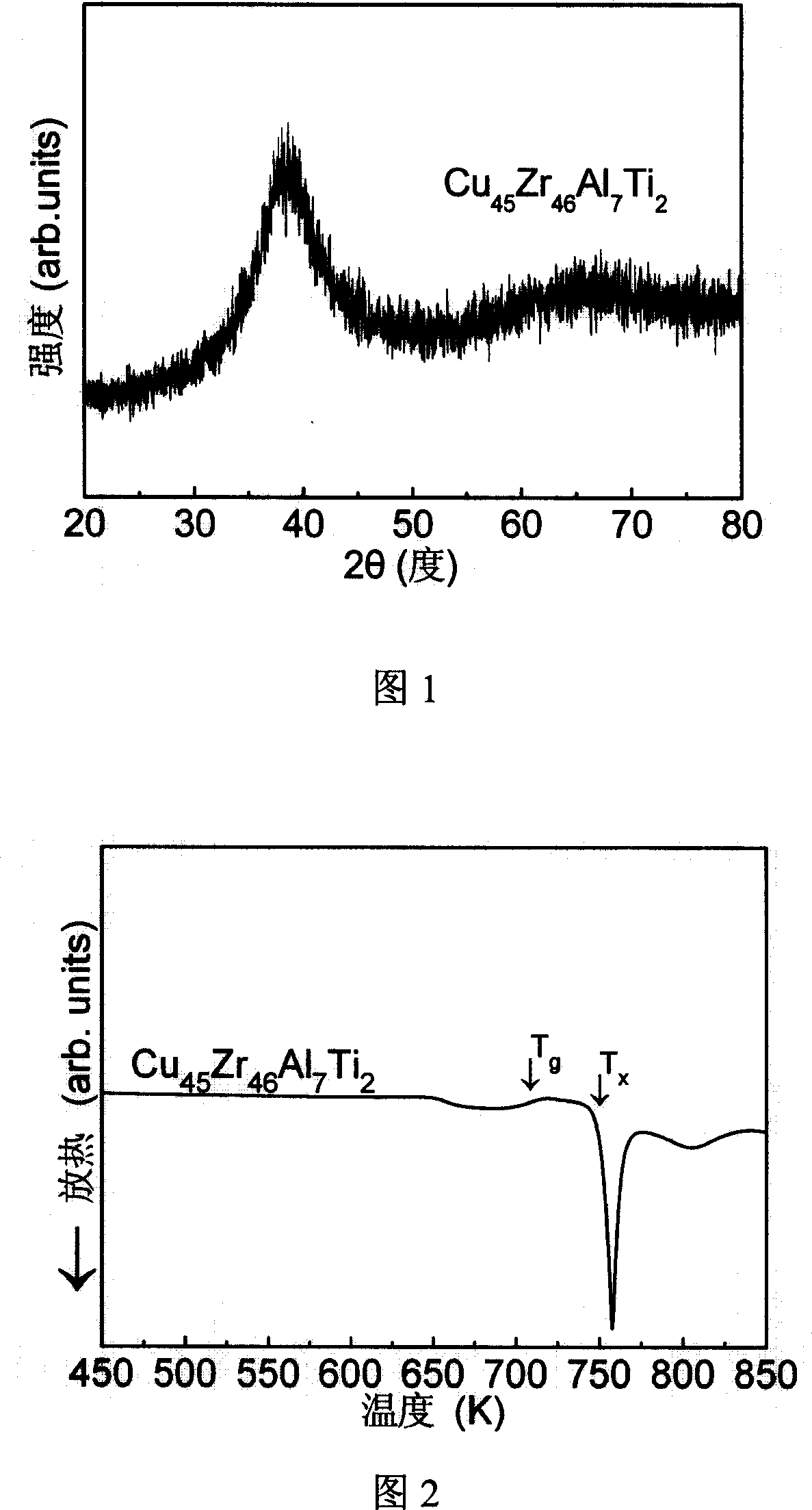

[0020] Step 4: Characterize the bulk amorphous structure by X-ray diffraction method, and Fig. 1 is the X-ray diffraction diagram of the sample.

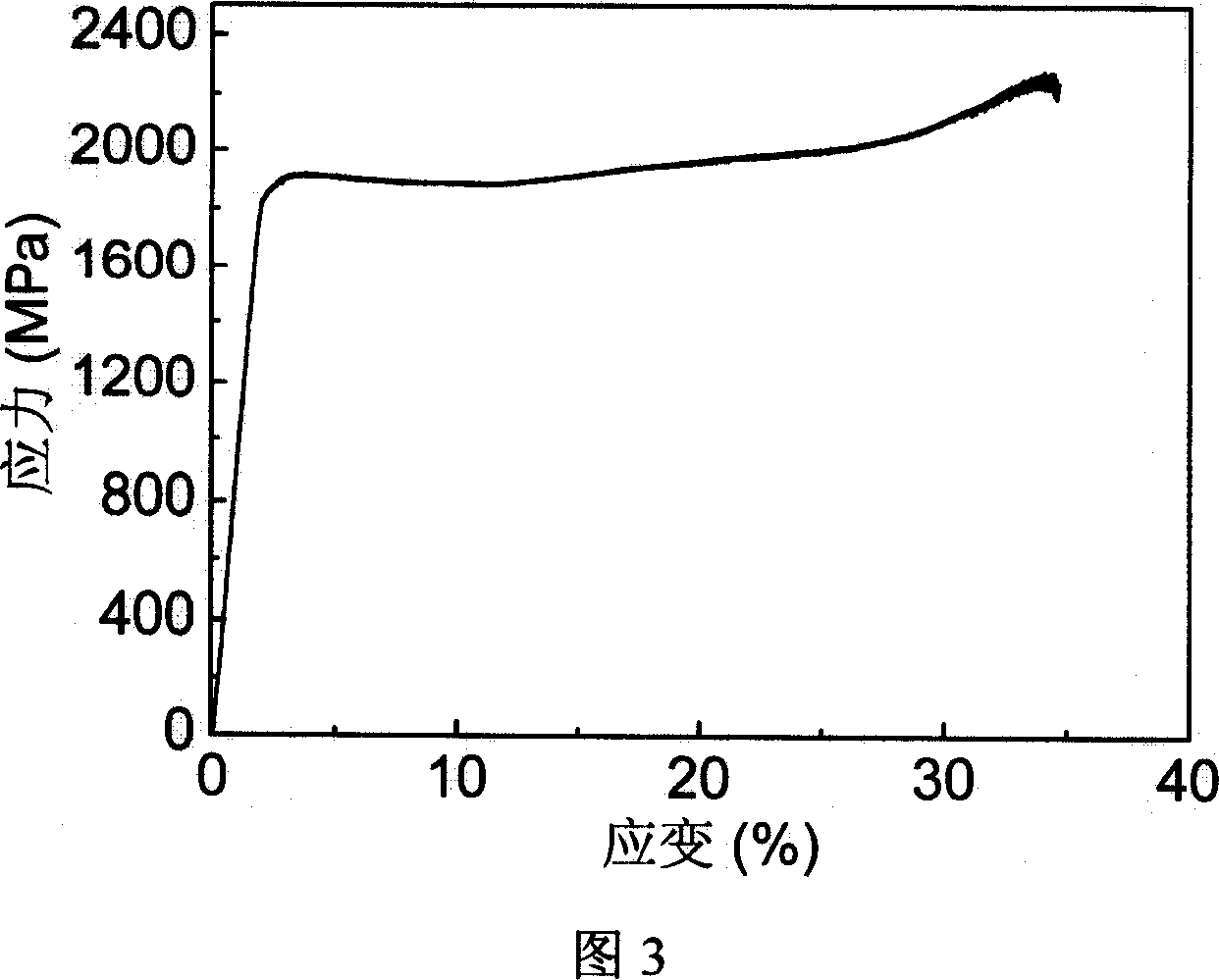

[0021] Step 5: Obtain the thermodynamic parameters of the bulk sample u...

Embodiment 2

[0027] This embodiment adopts suction casting method to prepare the Cu of diameter 10mm 45 Zr 46.5 al 7 Ti 1.5 Bulk amorphous alloys (amorphous alloys whose size reaches the order of millimeters are called bulk amorphous alloys).

[0028] Step 1: Put 99.95% pure Cu, 99.87% pure Zr, 99.5% pure Al and 99.98 pure Ti into Cu 45 Zr 46.5 al 7 Ti 1.5 The ratio is arc smelted in an argon atmosphere adsorbed by zirconium to obtain a uniformly mixed alloy ingot.

[0029] Step 2: Melt the ingot obtained in Step 1 on a water-cooled copper mold in an argon-protected melting furnace.

[0030] Step 3: inject the alloy liquid obtained in Step 2 into a water-cooled copper mold with an inner diameter of 10 mm by using the pressure difference. A bulk amorphous alloy is produced.

[0031] Step 4: Characterize the bulk amorphous structure by X-ray diffraction.

[0032] Step 5: Obtain the thermodynamic parameters of the bulk sample using differential scanning calorimetry.

Embodiment 3

[0034] This embodiment adopts suction casting method to prepare the Cu of diameter 10mm 45 Zr 47.5 al 7 Ti 0.5 Bulk amorphous alloys (amorphous alloys whose size reaches the order of millimeters are called bulk amorphous alloys).

[0035] Step 1: Put 99.95% pure Cu, 99.87% pure Zr, 99.5% pure Al and 99.98 pure Ti into Cu 45 Zr 47.5 al 7 Ti 0.5 The ratio is arc smelted in an argon atmosphere adsorbed by zirconium to obtain a uniformly mixed alloy ingot.

[0036] Step 2: Melt the ingot obtained in Step 1 on a water-cooled copper mold in an argon-protected melting furnace.

[0037] Step 3: inject the alloy liquid obtained in Step 2 into a water-cooled copper mold with an inner diameter of 10 mm by using the pressure difference. A bulk amorphous alloy is produced.

[0038] Step 4: Characterize the structure of the bulk amorphous by X-ray diffraction

[0039] Step 5: Obtain the thermodynamic parameters of the bulk sample using differential scanning calorimetry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com