Silicon base covariant underlay with the ultrathin carbon silicon middle layer and its preparing method

An interlayer, silicon carbide technology, applied in sustainable manufacturing/processing, climate sustainability, final product manufacturing, etc., can solve problems such as difficulty in realizing 3C-SiC thin films, inability to obtain, etc., and achieve a good mismatch strain coordination effect , to avoid the problem of impurity pollution, the effect of improving the growth quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

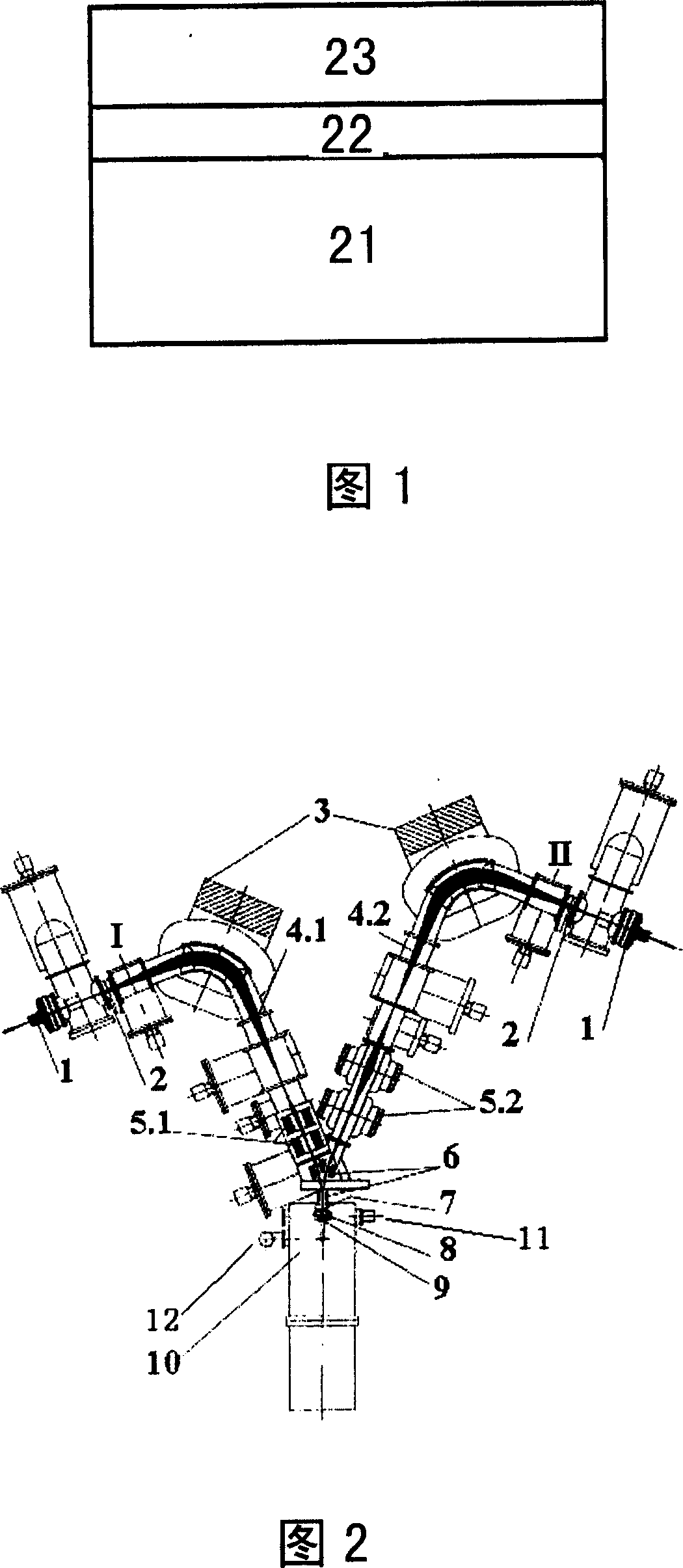

[0048] Please refer to Fig. 1 again, a method for preparing a silicon-based variable substrate with an ultra-thin silicon carbide intermediate layer according to the present invention is characterized in that the preparation method includes the following steps:

[0049] Take a silicon substrate 21;

[0050] Preparing an ultra-thin 3C-SiC intermediate layer 22 on a silicon substrate 21 by ion beam epitaxy;

[0051] An epitaxial layer 23 is prepared on the ultra-thin 3C-SiC intermediate layer 22 by magnetron sputtering.

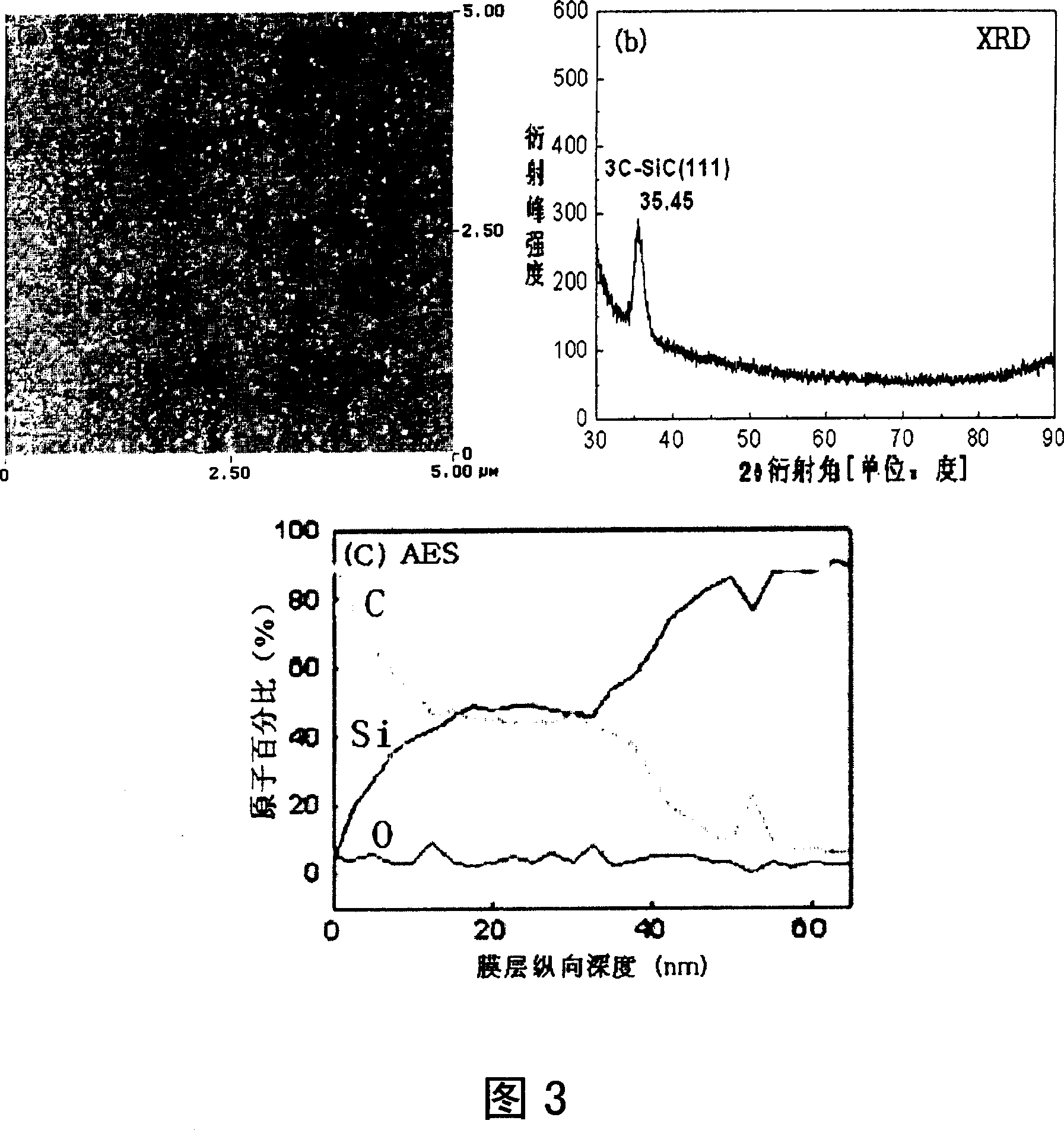

[0052] The preparation steps of the ultra-thin 3C-SiC intermediate layer 22 are as follows:

[0053] Step 1: Select argon gas with low purity requirements as the I-beam ion source of the low-energy dual ion beam epitaxy equipment to generate argon ion beam raw materials for dry sputtering cleaning of the substrate surface;

[0054] Step 2: Select carbon monoxide gas with low purity requirements as the low-energy dual ion beam epitaxy equipment II beam ion sou...

Embodiment

[0072] The structure of the silicon-based covariable substrate with an ultra-thin silicon carbide interlayer is shown in Figure 1, and its main technical parameters are shown in Table 1.

[0073] Table 1: Main technical parameters of silicon-based variable substrate with ultra-thin silicon carbide interlayer

[0074]

Supporting substrate 21

Material

Silicon (Si)

Thickness (μm)

300-500

crystal quality

Covariant middle layer 22

Material

Cubic silicon carbide (3C-SiC)

Thickness (nm)

5-30

crystal quality

single crystal or polycrystalline

Mismatched Epitaxial Layer 23

Lattice mismatch with substrate 1

Not less than 10%

[0075] crystal with covariable interlayer 2

Not more than 10%

crystal quality

single crystal or polycrystalline

[0076] Referring to the schematic diagram of the S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com