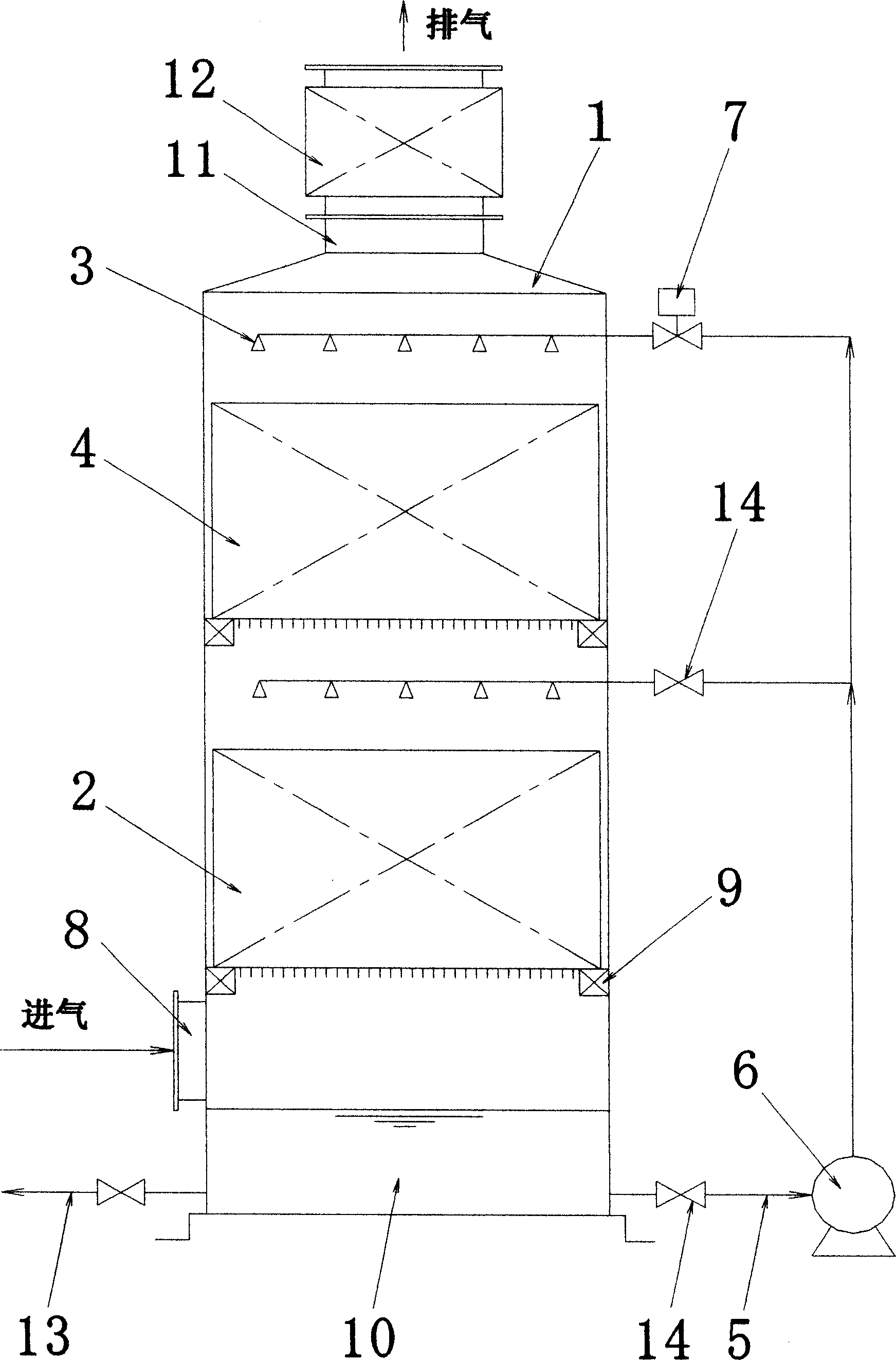

Biological deodorizing device

A technology of biological deodorization and stage filtration, which is applied in the directions of deodorization, separation of dispersed particles, and air quality improvement, and can solve the problems of increased wind resistance, increased operating costs, and increased ventilation load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with embodiment and accompanying drawing thereof further illustrate the patent of the present invention.

[0009] In the embodiment shown in the figure, when the organic waste gas containing high-concentration malodorous components is sent to the shell 1 of the biological deodorization device through the waste gas inlet pipe 8, it will forcibly flow from bottom to top into the first set. In the first-stage filter device 2, when it is in contact with the moisture and aerobic microorganisms that are adsorbed and fixed and live on the surface of the porous cylindrical ceramic carrier, the circulating treatment water tank arranged at the bottom of the first-stage filter device 2 and the The manual control valve 14 connected with the circulating water inlet pipe 5 and the circulating water pump 6, the manual control valve 14 is opened, the circulating water pump 6 is started, and a group of spraying water drying devices 3, spraying water drying devices 3,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com