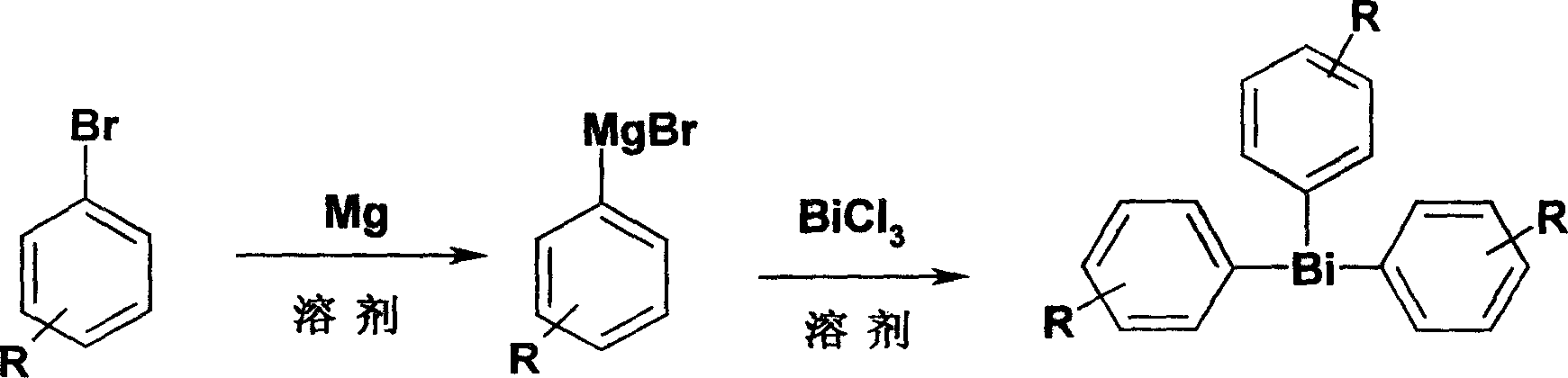

Industrial prepn process of triphenyl bismuth compounds

A technology of triphenyl bismuth and compounds, applied in the direction of bismuth organic compounds, etc., can solve the problems of being unsuitable for industrial production, and achieve the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

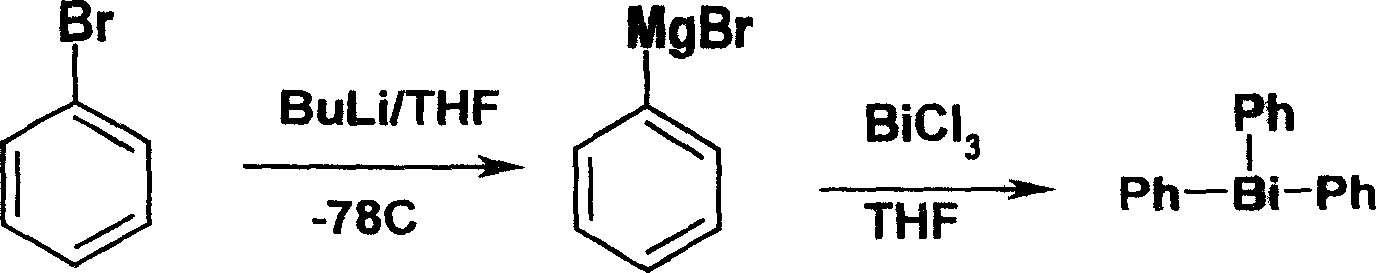

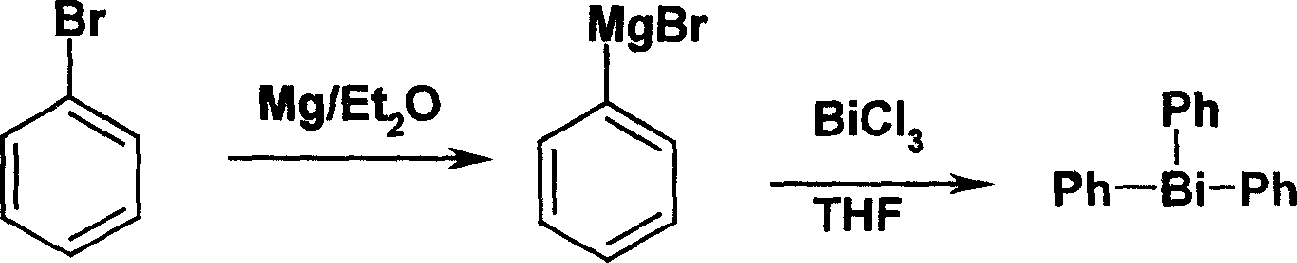

[0018] The preparation of example 1, triphenylbismuth

[0019] In a 500L reaction flask, add 6Kg of magnesium chips, 0.2Kg of iodine particles, 0.2Kg of bromobenzene, 10L of tetrahydrofuran and 30L of toluene, heat to 64°C, activate the magnesium chips for about 30 minutes, add dropwise a mixture of 38kg of bromobenzene and 150L of toluene For the mixed solution, control the dropping speed to maintain the reaction solution in a slightly boiling state. After the dropwise addition, react at 65-75°C for 5 hours to make the action of magnesium chips complete, cool to room temperature, and add dry bismuth trichloride 24.2 Kg and 100L dry toluene mixture was added in batches, after the addition was completed, reacted at 110°C for 4 hours, after the reaction was completed, cooled, stopped the reaction with a saturated aqueous solution made of 10Kg ammonium chloride, extracted with toluene, recrystallized, and filtered , After drying, 30.1 Kg of milky white crystalline triphenylbismut...

example 2、 3

[0020] The preparation of example 2, three (p-methylphenyl) bismuth

[0021] In a 500L reaction flask, add 6Kg, 0.2Kg iodine particles, 0.2Kg p-bromotoluene, 10L N-methylpyrrolidone and 30L benzene, heat to 80°C to activate magnesium chips for about 30 minutes, cool to 20°C, Add a mixture of 41.5Kg p-bromotoluene and 150L benzene dropwise at ℃, control the rate of addition, and control the reaction temperature at about 20℃. After the dropwise addition, continue to react at 20℃ for 15 hours to complete the reaction of magnesium chips. Add 24.2Kg of dry bismuth trichloride and 100L of dry benzene mixture in batches under stirring. After the addition is complete, react at 80°C for 9 hours. The aqueous solution was used to stop the reaction, extracted with benzene, recrystallized, filtered, and dried to obtain 34.2Kg of white crystal tris(p-methylphenyl)bismuth, with a yield of 92.4%, melting point: 88°C to 89°C, (literature value: 86°C ~87°C).

example 3

[0022] The preparation of example 3, three (m-methylphenyl) bismuth

[0023] In a 500L reaction flask, add 6.2Kg of magnesium chips, 0.2Kg of iodine grains, 0.2Kg of m-bromotoluene, 10L of N-methylpyrrolidone and 30L of ethylbenzene, heat to 120°C, activate the magnesium chips for about 30 minutes, then add For the mixture of 41.5Kg bromotoluene and 150L ethylbenzene, control the rate of addition to maintain the reaction temperature at 120°C. After the dropwise addition, continue to react at 120°C for 1 hour to make the action of magnesium chips almost complete. Cool to room temperature and add dry The mixture of 24.2Kg of bismuth trichloride and 100L of dry ethylbenzene was added in batches. After the addition was completed, it was reacted at 120°C for 1 hour. After extraction with ethylbenzene, recrystallization, filtration and drying, 34Kg of white crystalline tris(m-methylphenyl)bismuth was obtained, with a yield of 92.0%. Melting point: 78°C-79°C (literature value: 78°C-7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com