Ruthenium porphyrin complex and its prepn process and application as photosensitizer for photodynamic therapy

A complex, ruthenium porphyrin technology, applied in the field of photodynamic therapy photosensitizer ruthenium porphyrin complex and its preparation, can solve the problems of large phototoxic side effect, poor absorption and metabolism of photosensitizer, uncertain composition and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

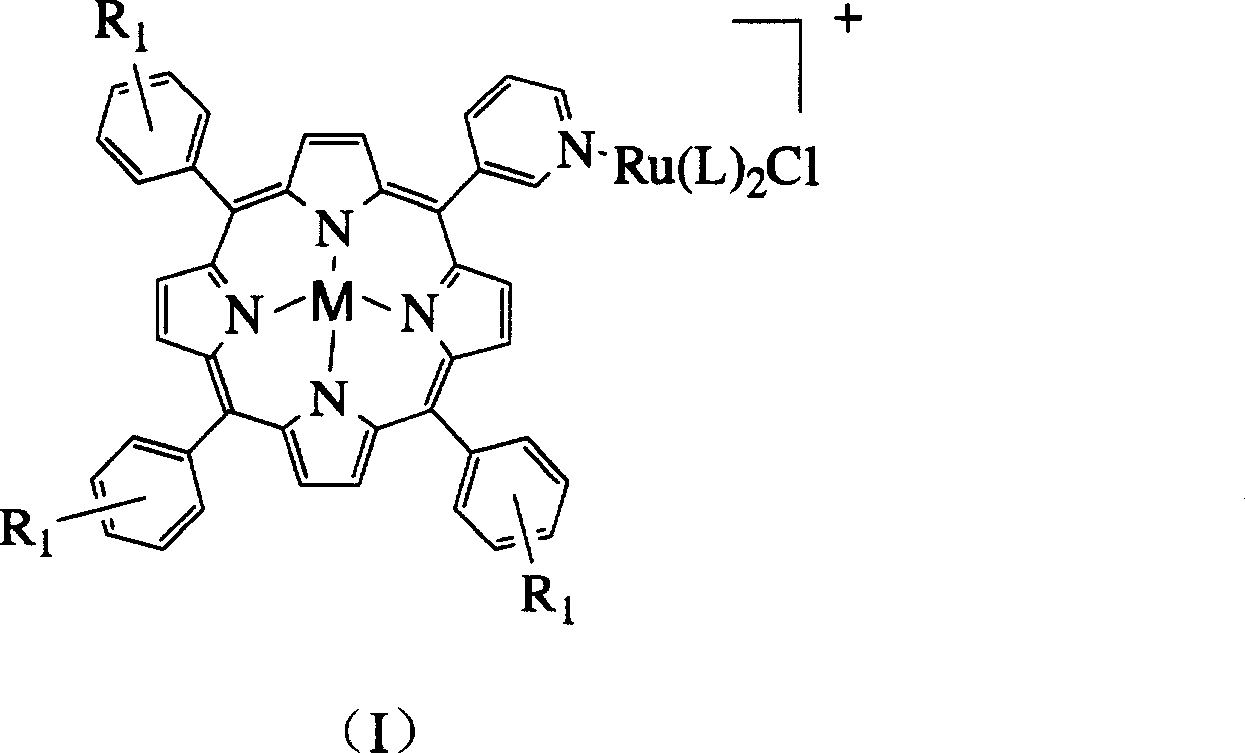

[0042] Embodiment 1 [Ru(bpy) 2 Synthesis of (Cl)(m(3'-Py)TPP)]Cl cis-[Ru(bpy) 2 Cl 2 ]·2H 2 Synthesis of O: RuCl 3 ·nH 2 O (6mmol), bipyridine (12mmol) and lithium chloride (28mmol) were placed in a three-necked flask, 10mL of DMF was added, and heated to reflux for 8 hours under the protection of argon. After cooling to room temperature, 50 mL of acetone was added and frozen overnight. After suction filtration, the precipitate was washed several times with ice water and cold acetone, and dried in vacuo to obtain purple-black microcrystals with a yield of 81% (calculated as bipyridine).

[0043] m(3′-Py)TPP(123mg) and cis-[Ru(bpy) 2 Cl 2 ]·2H 2 O (123 mg) in acetic acid solution (10 mL) was refluxed for 24 hours. After the reaction, a purple-red solution was obtained, which was spin-dried under reduced pressure to obtain a purple-red homobody. The crude product was dissolved in acetonitrile and separated by neutral alumina column chromatography, rinsed with acetonitr...

Embodiment 2

[0044] Embodiment 2 [Ru(phen) 2 Synthesis of (Cl)(m(3'-Py)TPP)]Cl

[0045] Cis-[Ru(phen) 2 Cl 2 ]·2H 2 See Example 1 for the synthesis of O.

[0046] [Ru(phen) 2 Synthesis of (Cl)(m(3′-Py)TPP)]Cl: m(4′-Py)TPP (123mg) and Cis-[Ru(phen) 2 Cl 2 ]·2H 2 O (123 mg) in acetic acid solution (10 mL) was refluxed for 24 hours. After the reaction, a purple solution was obtained, which was spin-dried under reduced pressure. A purple solid was obtained. The crude product was dissolved in acetonitrile and separated by neutral alumina column chromatography, rinsed with acetonitrile:methanol (2:1, v / v), and the purple-red color band was collected, spin-dried under reduced pressure, and then recrystallized in acetonitrile / toluene solution. Yield 82%.

Embodiment 3

[0047] Embodiment 3 [Ru(dmbpy) 2 Synthesis of (Cl)(m(4'-Py)TPP)]Cl

[0048] Cis-[Ru(dmbpy) 2 Cl2 ]·2H 2 See Example 1 for the synthesis of O.

[0049] m(4′-Py)TPP(123mg) and Cis-[Ru(dmbpy) 2 Cl 2 ]·2H 2 O (123 mg) in acetic acid solution (10 mL) was refluxed for 24 hours. After the reaction, a purple solution was obtained, which was spin-dried under reduced pressure. Get the same body of purple. The crude product was dissolved in acetonitrile and separated by neutral alumina column chromatography, rinsed with acetonitrile:methanol (2:1, v / v), and the purple-red color band was collected, spin-dried under reduced pressure, and then recrystallized in acetonitrile / toluene solution. Yield 81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com