Extract-agitating self-suction type biological reactor

A technology of bioreactor and reactor, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instrument, etc. To avoid problems such as poor quality and effect, to increase the effect of gas-liquid mixing, easy to operate, and simple in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

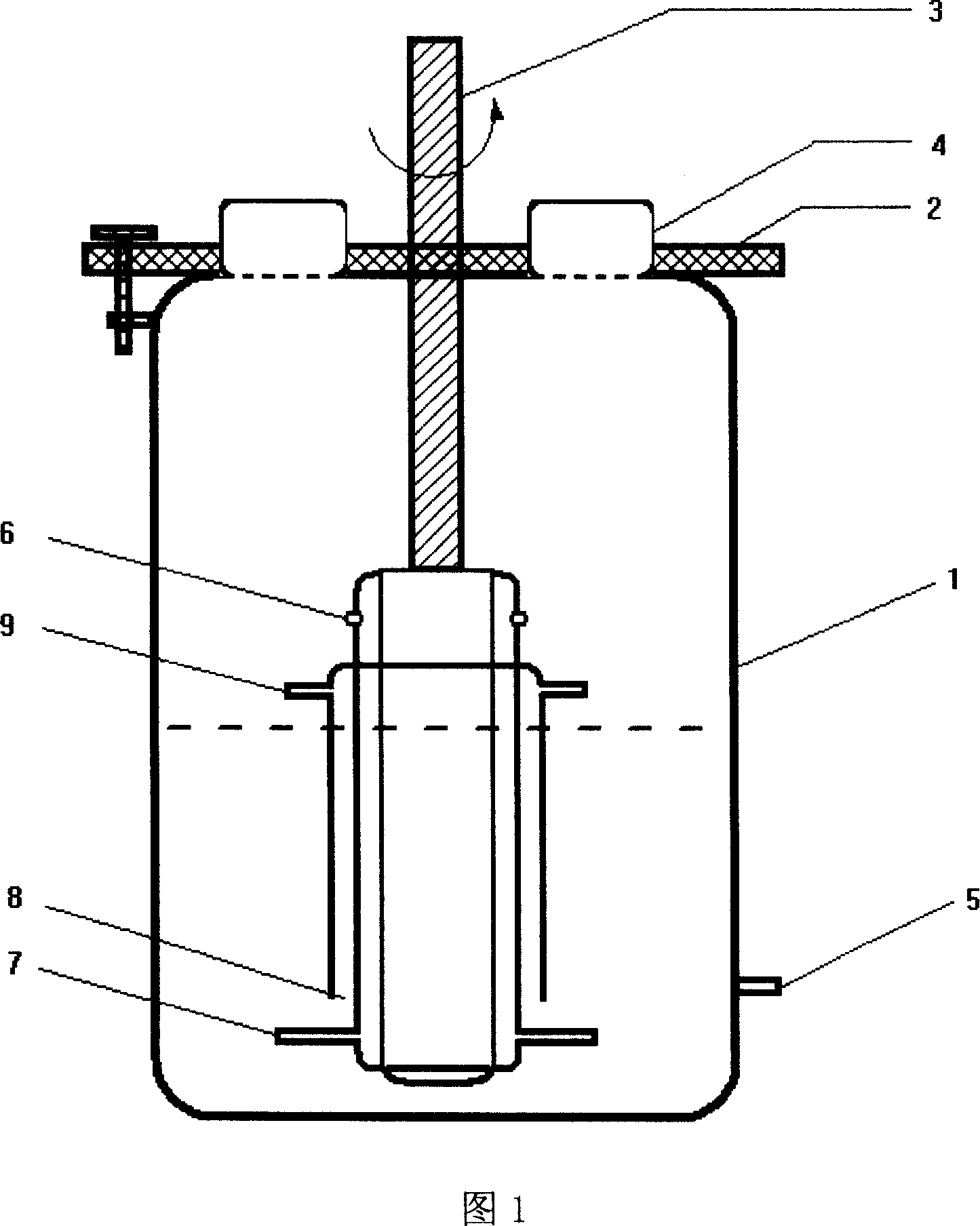

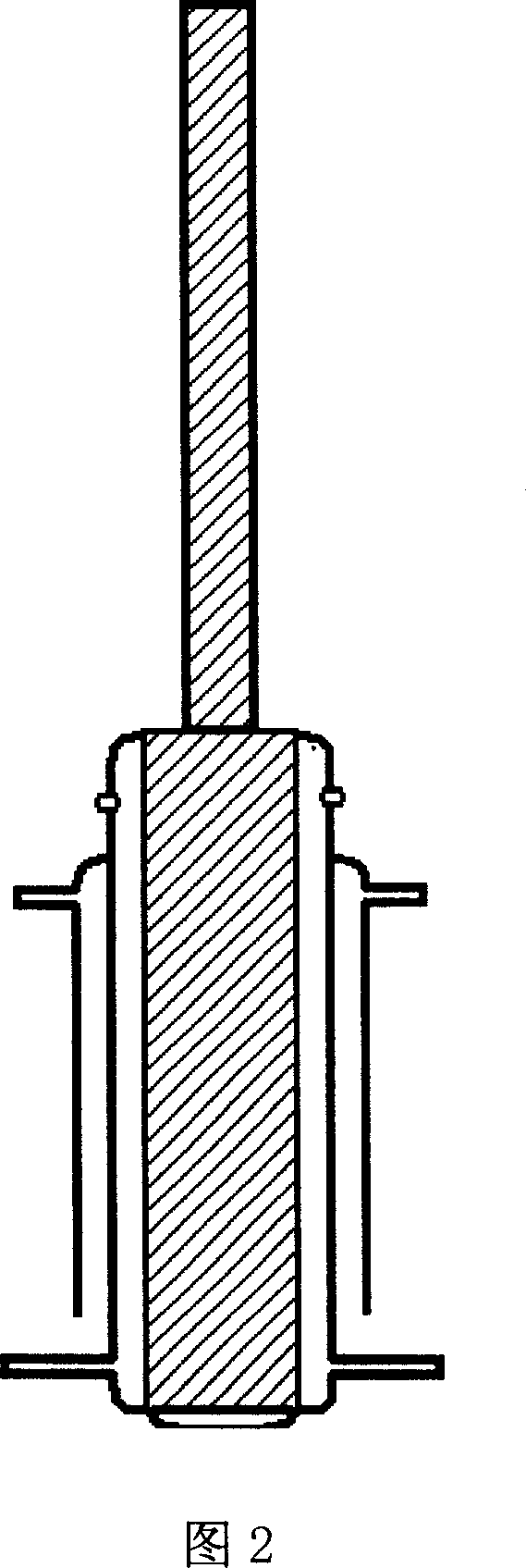

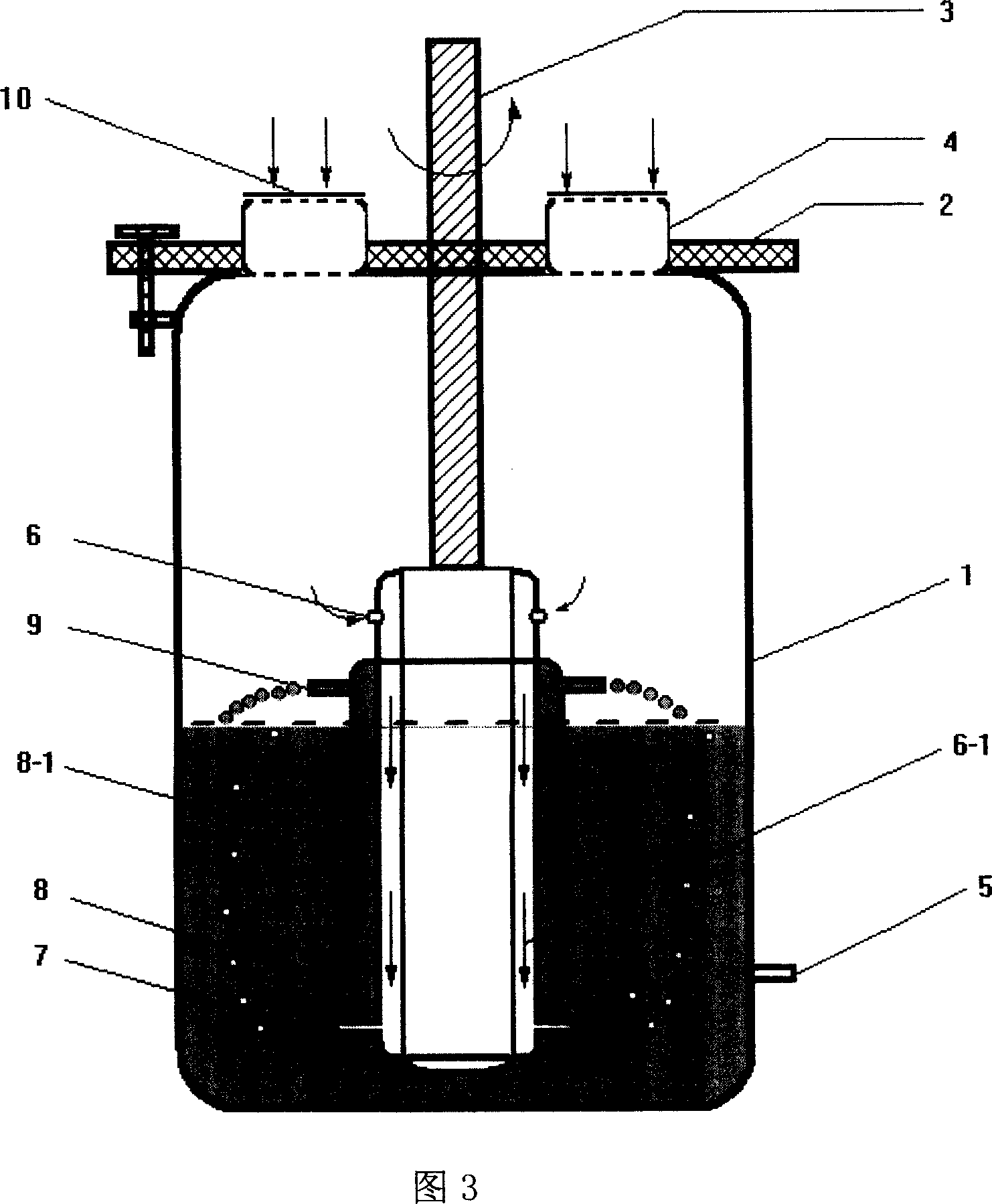

[0033] Referring to Figures 1 to 3, a stirred liquid self-priming bioreactor that can be used for cell fermentation reactions is produced according to the connection relationship of the aforementioned reactors.

[0034] The stirred liquid self-priming bioreactor provided in this example has an inner diameter of 74 mm, a height of 135 mm, a volume of 500 mL, and an effective volume of 200 mL. The upper half of the central shaft is 110mm long and has an inner diameter of 6mm; the lower half is 70mm long and has an inner diameter of 25mm. The outer cavity sleeve (gas phase sleeve) is 70mm high, and two Ф5mm small holes are opened at the upper end of the outer cavity sleeve at 5mm, and two gas phase centrifugal forces with a length of 10mm and an inner diameter of Ф2mm are connected at the lower end of the outer cavity sleeve at 5mm. Tube channel. The inner cavity sleeve (liquid phase sleeve) is attached to the outside of the outer cavity sleeve, the lower end is open, and the he...

Embodiment 2

[0036] Made according to Example 1, and in the reactor that has been made in Example 1, an electric heating tube is installed, and the heating tube is electrically connected with an external temperature controller, or an external heat exchange type ventilation tube is placed in the lower part of the reactor shell. The jacket of hot and cold water is electrically connected with the external temperature controller.

Embodiment 3

[0038] The fermentative culture of the biocatalytic desulfurization strains was carried out in the stirred liquid self-priming bioreactor made in Example 1 or Example 2. The steps are as follows:

[0039] (1) Seed culture of biological desulfurization bacteria

[0040] Take 0.5 mL of Pseudomonas delafildii R-8 strain (Pseudomonas delafildii R-8, CGMCC NO.0570) preserved in glycerol, add it to the medium with a volume of 20-50 mL, and put it under the condition of 30°C and 170r / min Cultivate for 1 to 2 days;

[0041] The composition of the medium is 2.44 g KH per liter of water 2 PO 4 , 14.03 g Na 2 HPO 4 12H 2 O, 0.4g MgCl 2 ·6H 2 O, 0.001g CaCl 2 2H 2 O, 0.001g FeCl 3 ·6H 2 O, 0.004gMnCl 2 4H 2 O, 10 g glycerol and 2.00 g NH 4 Cl. The sulfur source is dibenzothiophene with a concentration of 0.1 mmol / L.

[0042] (2) Stirring liquid self-priming bioreactor experiment

[0043] Add 200 mL of the above-mentioned culture medium into the reactor, and sterilize wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com