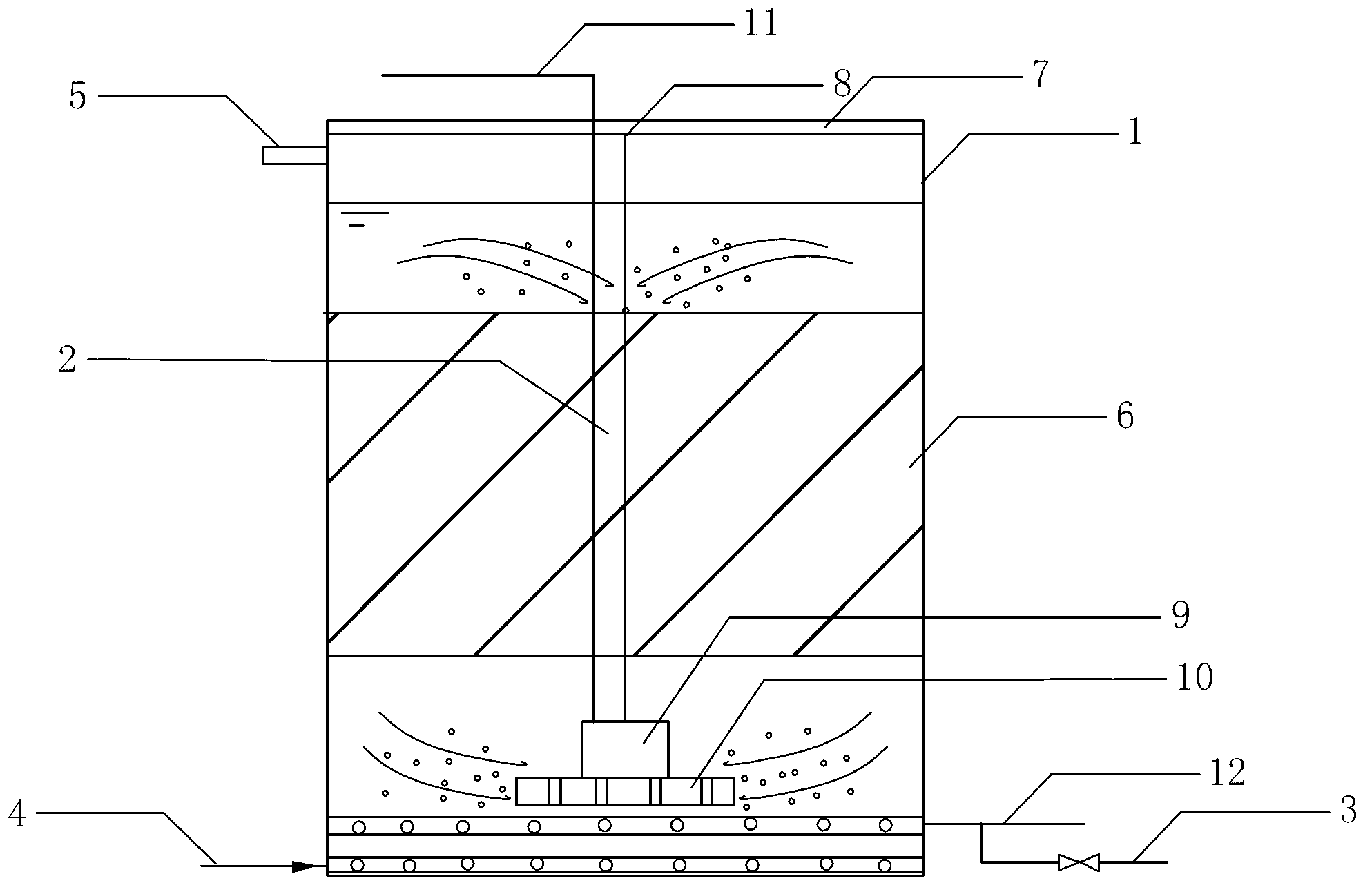

Novel diving jet-type biological aerated filter

An aerated biological filter, biological filter technology, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Unfavorable microbial growth, pollutant metabolism, affecting sewage treatment effect, etc., to achieve the effect of improving effluent treatment effect, improving oxygen transfer efficiency, and improving gas-liquid mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] To treat a domestic sewage, the raw water quality condition is: chemical oxygen demand (COD cr ) content 250-300mg / L, biological oxygen demand (BOD 5 ) content of 120-150mg / L, ammonia nitrogen of 8-10mg / L, and total nitrogen (TN) of 20-25mg / L. Through self-priming jet aerated biological filter treatment, the water retention time is 4 hours. After the system runs stably for a period of time, after the sewage is treated, the final effluent COD cr Below 20mg / L, BOD 5 The ammonia nitrogen is less than 5mg / L, the ammonia nitrogen is 2-5mg / L, and the total nitrogen is less than 10mg / L. The effluent meets the first-class A standard of the "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002).

Embodiment 2

[0022] Treatment of an industrial waste water, the waste water is a food production waste water, the raw water quality condition is: COD cr Content 500-700mg / L, BOD 5 The content is 300-400mg / L, the ammonia nitrogen is 10-20mg / L, and the total nitrogen is 30-40mg / L. This kind of wastewater has good biodegradability, so it is directly treated through the self-priming jet aerated biological filter, and the water retention time is 6 hours. After the system runs stably for a period of time, after the sewage is treated, the final effluent COD cr Below 30mg / L, BOD 5 The ammonia nitrogen is less than 5mg / L, the ammonia nitrogen is 2-5mg / L, the total nitrogen is less than 10mg / L, and the effluent meets the first-class A standard of the industry.

[0023] The present invention uses a submersible jet aerator to replace the original blast aeration equipment, and the air filled in is forced to mix with the liquid in the casing, so excellent gas-liquid mixing effect can be obtained. At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com