Connector sheet and portable electronic apparatus

A technology of electronic equipment and connection sheet, which is applied in the direction of connection, two-part connection device, parts of connection device, etc. It can solve the problems of difficult to realize conductive properties, hard and brittle rubber, high cost, etc., and achieve less misoperation , Prevent static electricity, improve productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

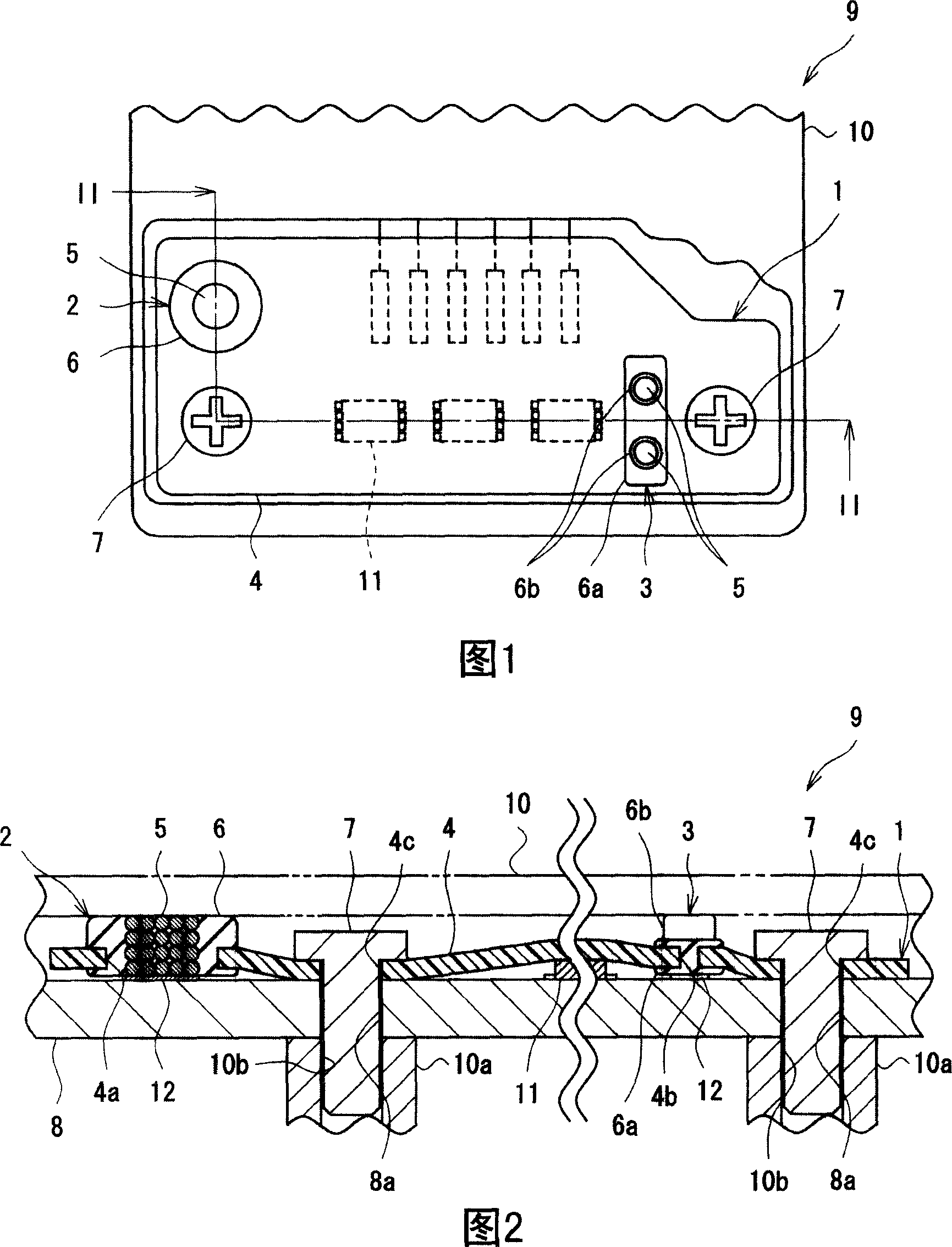

[0049] First Embodiment ( FIGS. 1 to 3 ): A connecting sheet 1 of the first embodiment includes two connector parts 2 and 3 and a resin sheet 4 as a "sheet part".

[0050] The first connector part 2 is formed of a rubber-like elastic body such as silicone rubber. The connector part 2 has a conducting part 5 and an insulating part 6 . Among them, the conduction part 5 is located at the center of the connector part 2, and is formed in a cylindrical shape in which magnetic fine conductive particles are aligned in the thickness direction of the connector part 2 (height direction along the axis). The insulating portion 6 is formed in a cylindrical shape so as to wrap around the outer periphery of the conduction portion 5 . A circular first through hole 4 a formed through the resin sheet 4 and its peripheral portion (hole edge portion) are embedded in the outer peripheral side surface of the insulating portion 6 . That is, the connector part 2 is formed so that it may penetrate th...

no. 2 approach

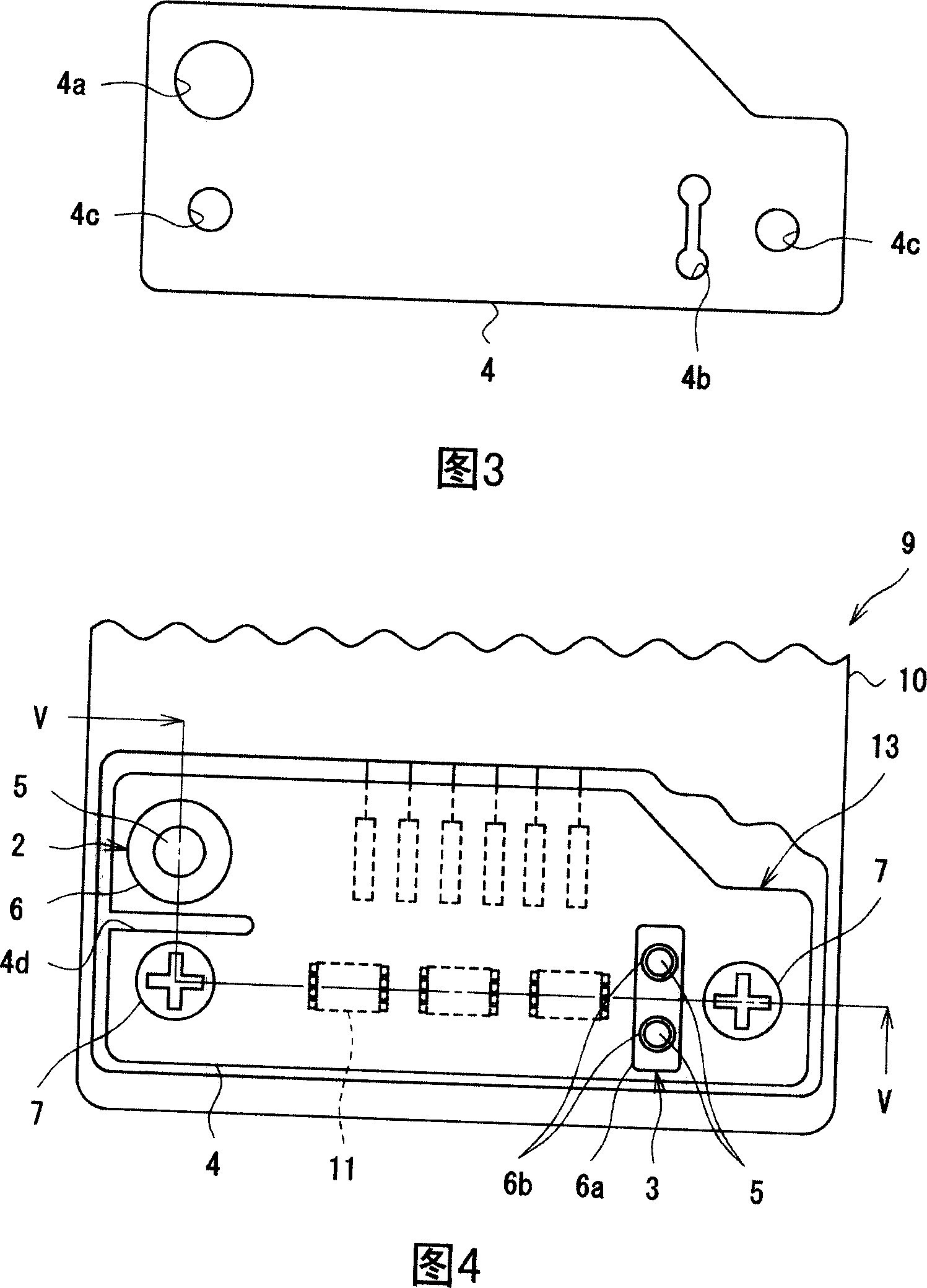

[0074] The second embodiment ( FIG. 4 and FIG. 5 ): the connection sheet 13 of the second embodiment is different from the connection sheet 1 of the first embodiment in the structure of the resin sheet 4 . The rest of the structure and its functions and effects are the same as those of the first embodiment.

[0075] In the resin sheet 4, notches 4d are formed between the insertion holes 4c adjacent to the first through holes 4a.

[0076] Next, an embodiment of the electronic device 9 including the connection sheet 13 of the second embodiment will be described. The electronic device 9 includes at least a connection piece 13 and a circuit board 8 inside a metal casing 10 made of, for example, a magnesium alloy. Like the connection sheet 1 , the connection sheet 13 is used to cover the circuit board 8 so as to cover the circuit elements 11 and the like arranged on the circuit board 8 . The circuit board 8 is fixed in the casing 10 with metal screws 7 . A ground connection port...

no. 3 approach

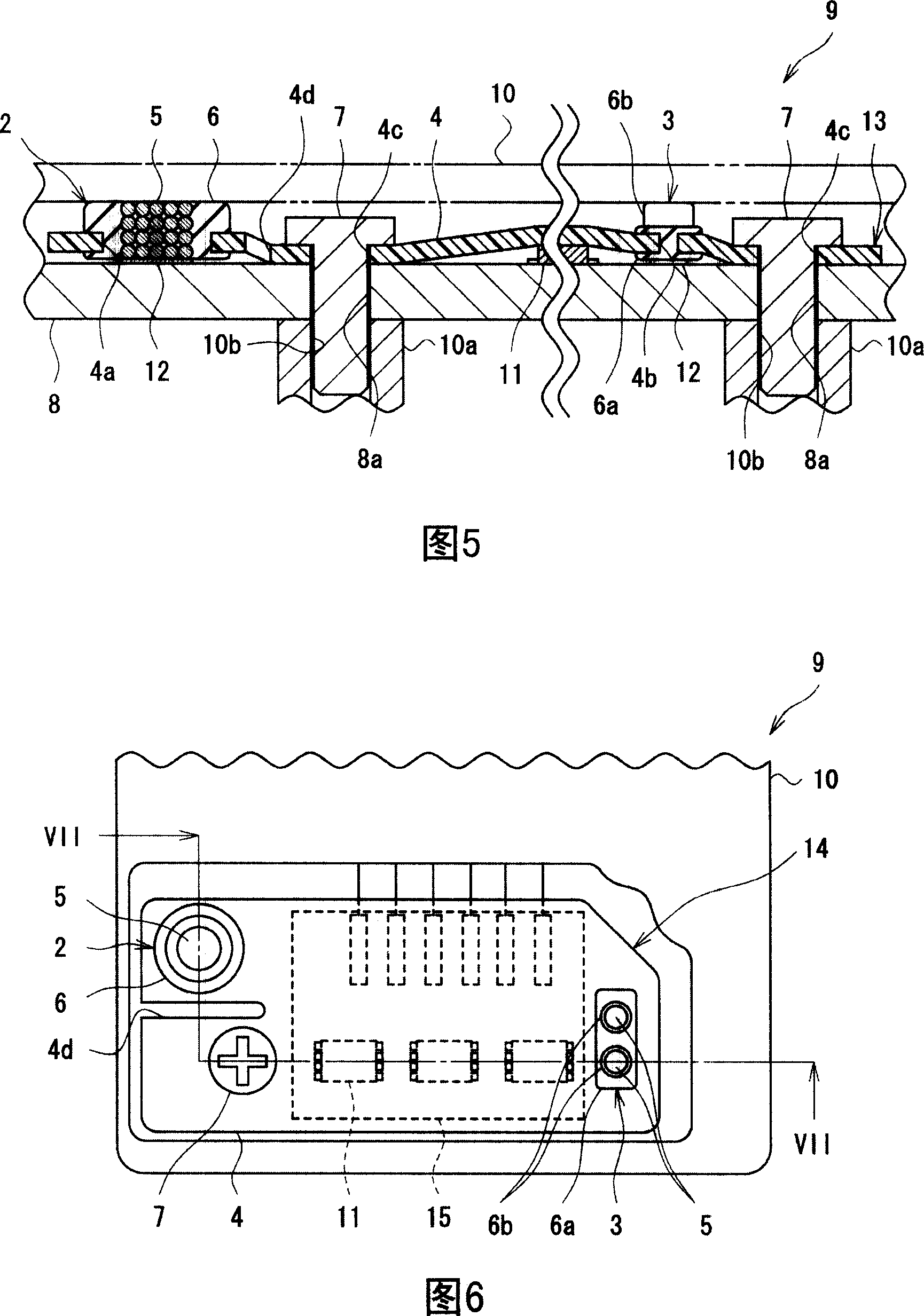

[0079] Embodiment 3 ( FIGS. 6 and 7 ): The connection sheet 14 of the third embodiment differs from the connection sheet 13 of the second embodiment in the structure of the connector part 2 and the resin sheet 4 . The rest of the structure and its functions and effects are the same as those of the second embodiment.

[0080] In the insulating part 6 of the connector part 2, the corners of both end surfaces are chamfered. That is, the connector portion 2 penetrates through the through hole 4 a of the resin sheet 4 , and is formed in a shape protruding from both surfaces of the resin sheet 4 in a truncated cone shape.

[0081] One insertion hole 4 c is formed in the resin sheet 4 , and an adhesive layer 15 is provided on the facing surface of the circuit board 8 . The adhesive layer 15 can be formed by applying an adhesive, sticking a double-sided tape, or the like.

[0082] Next, an embodiment of the electronic device 9 including the connection sheet 14 of the third embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com