Environmental protection composite envelope type slow release fertilizer

A slow-release fertilizer and coating technology, which is applied in the field of coated slow-release fertilizers and environmentally friendly composite coated slow-release fertilizers, can solve the problem of degradable materials with high water and fertilizer penetration rates, and degradable coated slow-release fertilizers. Short release period, etc., to achieve the effect of low cost, high barrier property and long release period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

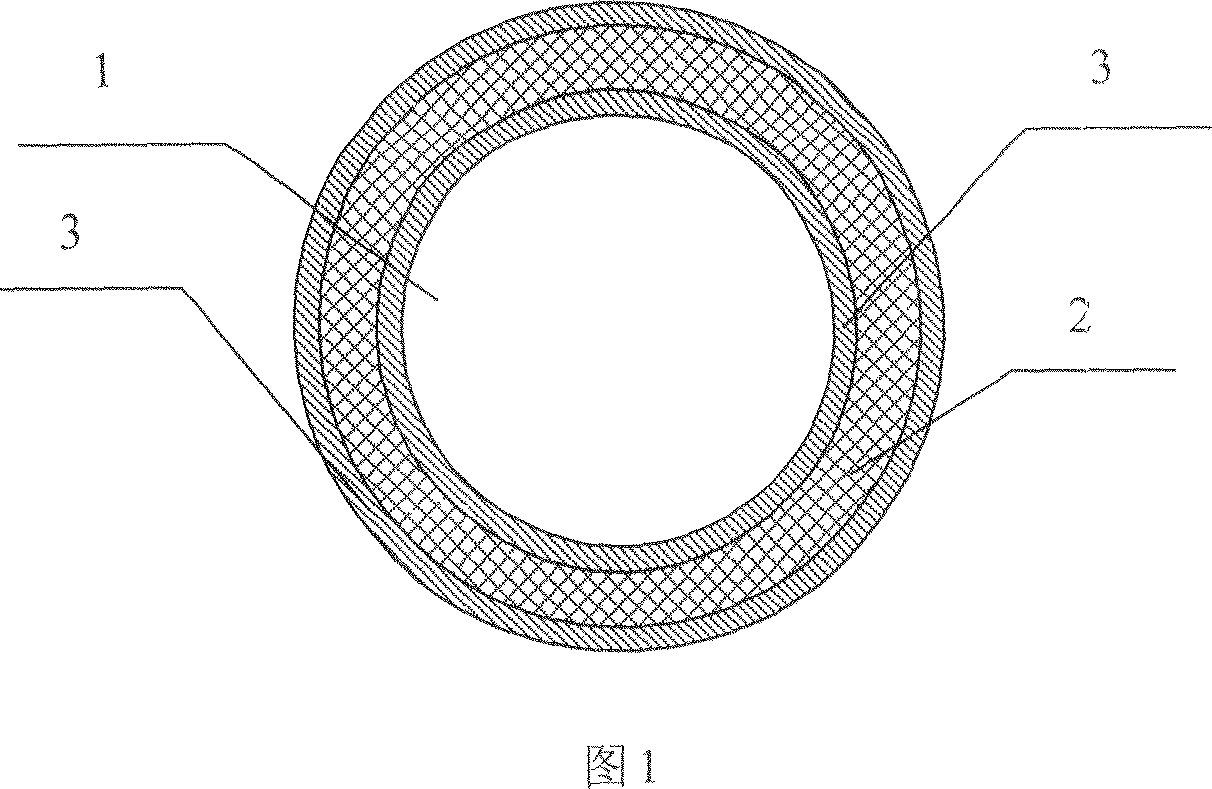

[0052] Add granular industrial urea with a particle size of 2.0 to 4.0mm into the fluidized bed coating equipment, and keep the granular urea in a boiling state, and keep the temperature of the granular urea in the fluidized bed at 80°C. The aqueous solution of urea-formaldehyde resin prepolymer (urea-formaldehyde resin prepolymer is prepared by reacting urea and formaldehyde with a urea:formaldehyde molar ratio of 1:2) and molten sulfur at about 150°C are sent from two groups of different nozzles to the surface of granular urea at the same time. Slowly spray, by controlling their spraying flow ratio, make the average mass fraction of sulfur in the formed thiourea-formaldehyde resin mixture film layer be 70%, spray until the quality of the formed layer of thiourea-formaldehyde resin mixture film layer reaches the final product environmental protection 6% of the total mass of composite-coated slow-release urea is dried to remove water contained in the film layer. Then, stop spr...

Embodiment 2

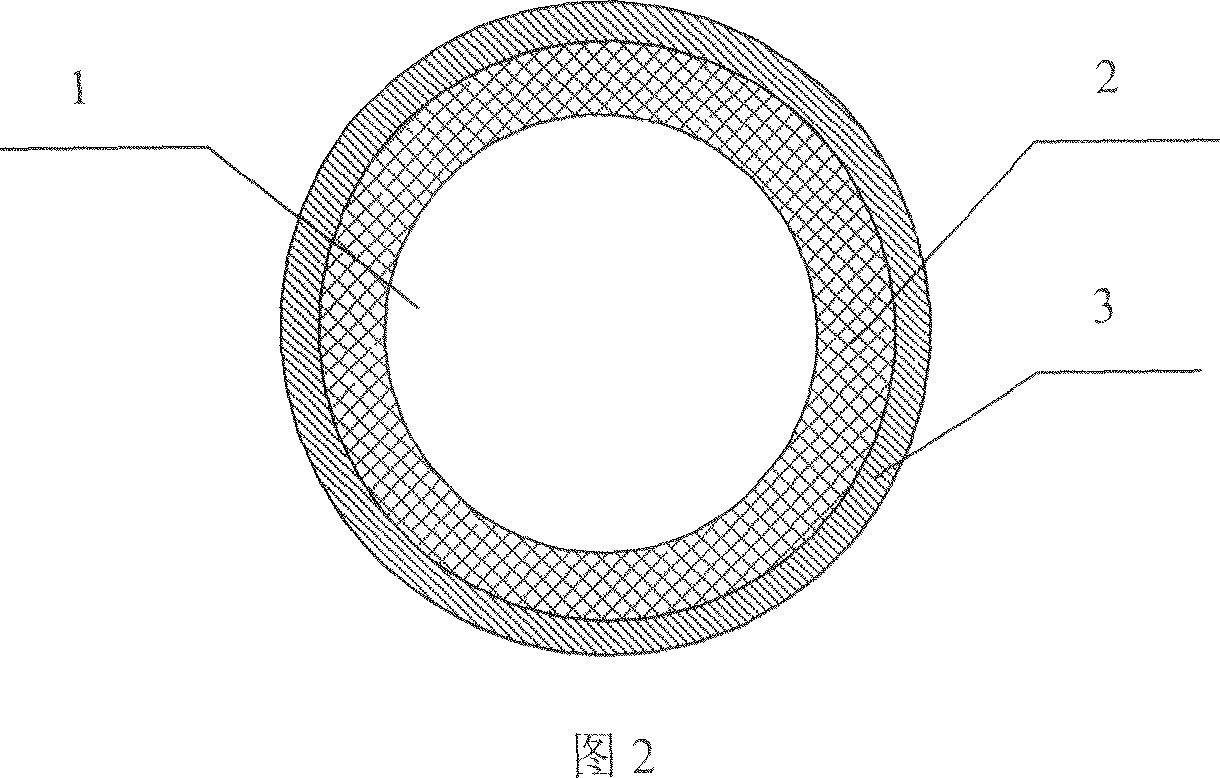

[0054] Add granular industrial urea with a particle size of 2.0 to 4.0mm into the fluidized bed coating equipment, and keep the granular urea in a boiling state, and keep the temperature of the granular urea in the fluidized bed at 90°C. Slowly spray molten sulfur at about 150°C on the surface of urea until the quality of the sulfur film reaches 7% of the total mass of the final product, environmentally friendly composite coated slow-release urea. Then, spray the sulfur-containing melamine-formaldehyde resin prepolymer aqueous solution (melamine-formaldehyde resin prepolymer is melamine: the melamine of formaldehyde mol ratio is 1: 3 is prepared by the reaction of melamine and formaldehyde containing sulfur at the surface of the sulfur film layer, sulfur: melamine- The mass ratio of the formaldehyde resin prepolymer is 7: 3), until the quality of the formed sulfur-containing melamine-formaldehyde resin mixture film layer reaches 8% of the total mass of the final product environ...

Embodiment 3

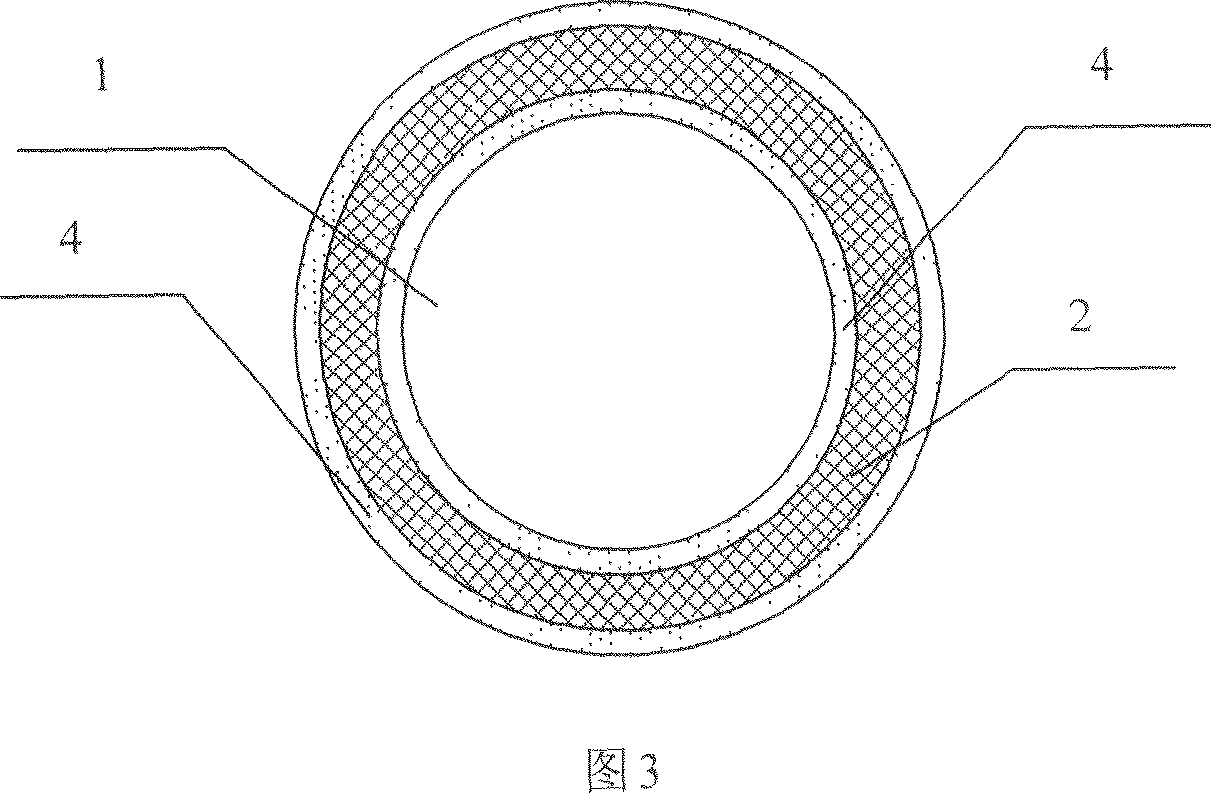

[0056] Add granular industrial urea with a particle size of 2.0 to 4.0mm into the fluidized bed coating equipment, and keep the granular urea in a boiling state, and keep the temperature of the granular urea in the fluidized bed at 90°C. The aqueous solution of melamine-formaldehyde resin prepolymer (melamine-formaldehyde resin prepolymer is prepared by the reaction of melamine and formaldehyde with a mol ratio of melamine: formaldehyde of 1:4) is sprayed on the surface of urea until the layer of melamine-formaldehyde resin film formed The quality of the layer reaches 2% of the total mass of the final product environmental protection composite film-coated slow-release urea, and the water in the film layer is removed by drying. Then, slowly spray molten sulfur at a temperature of about 150° C. on the surface of the melamine-formaldehyde resin film until the quality of the formed sulfur film reaches 11% of the total mass of the final finished environmentally friendly composite co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com