Preparing method and application for corrosion resistant composite SiO2 film

A corrosion-resistant and film-forming technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problems of high film-forming rate, uneven surface, cracking, etc., and achieve the effect of reducing the corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

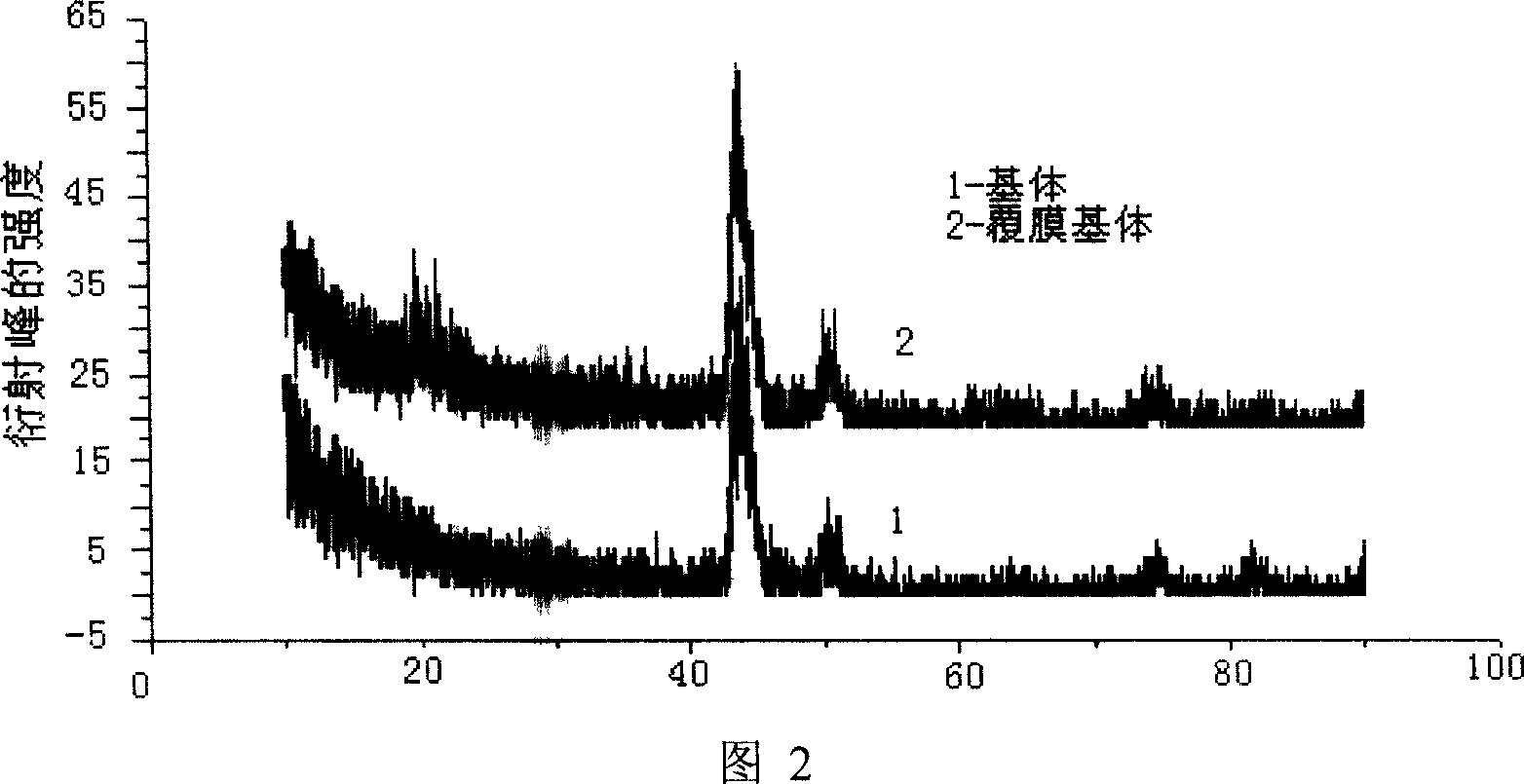

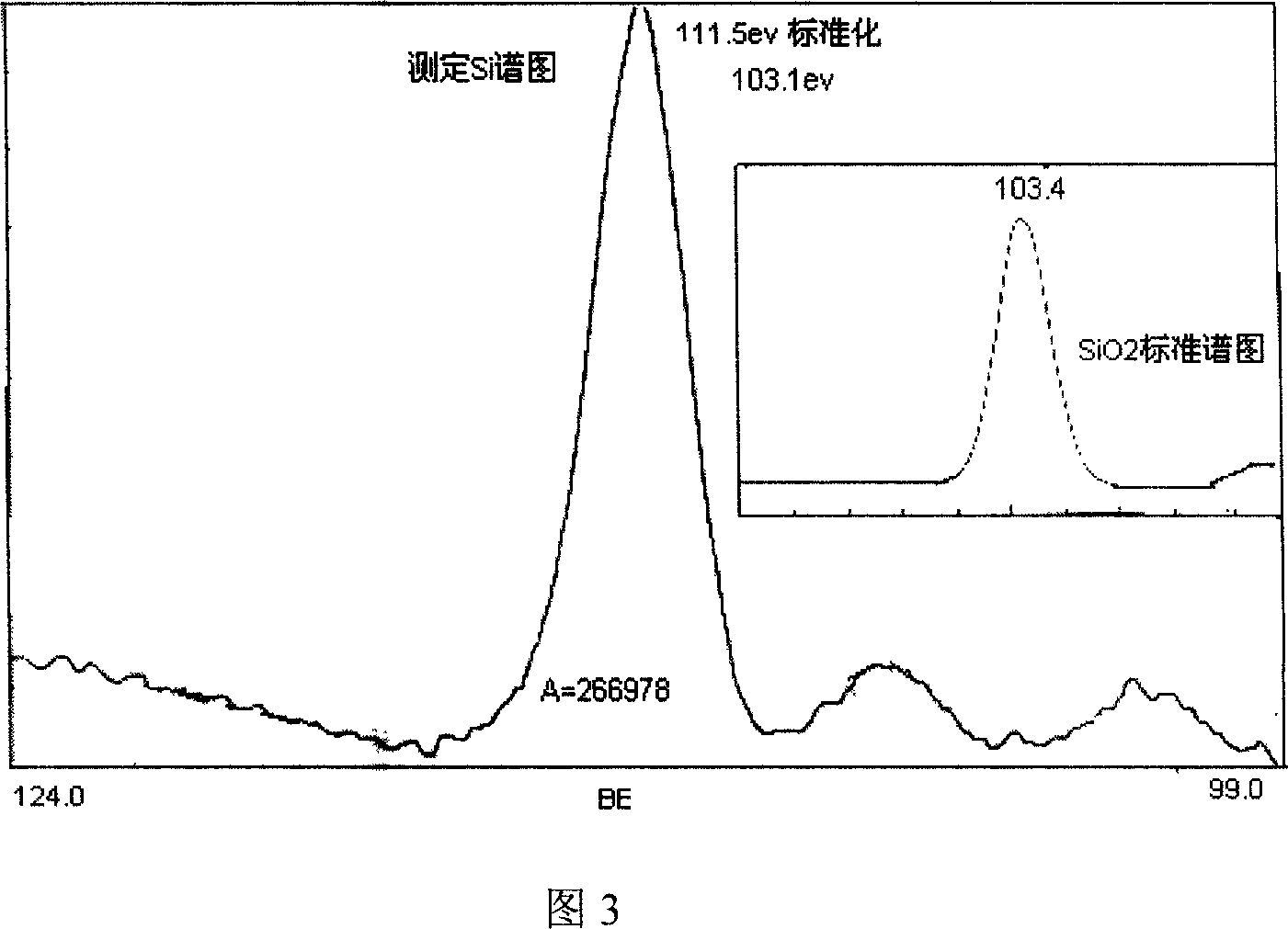

[0027]The substrate adopts SUS304 stainless steel sample of φ40mm×1mm. First, the sample was polished to 1200# with 600-1200# corundum water abrasive paper in sequence, deionized water was ultrasonically cleaned for 30 minutes, and degreased with acetone. Each group of experiments uses 3 samples in parallel, separates them with brackets, places them in ordinary Na-Ca glass containers, adds LiBr solution (about 100ml each time) with a concentration of 60% and PH=9.5, and puts them into a high-temperature and high-pressure reaction kettle Inside. According to the physical properties of LiBr solution at high temperature, the saturated vapor pressure is 0.17MPa when the concentration of LiBr solution is 60% and the temperature is 190°C, and the pressure at normal temperature is 0.23MPa according to the ideal gas state equation. First use a vacuum pump to evacuate the system to control the oxygen content in the kettle, so that the absolute pressure in the kettle is 1.30kPa to avoi...

Embodiment 2~4

[0029] Control the film-forming temperature at 200°C, adjust the concentration of LiBr solution to 45%, 55%, and 60%, respectively, and pour N 2 The pressure is 0.47, 0.29, 0.21MPa. All the other operating methods and process conditions are the same as in Example 1. The composition content and thickness of the prepared film are shown in Table 1. And measured the dynamic anodic polarization curve of the film formed in 200 ℃, 55% LiBr solution, it can be seen that pitting corrosion is effectively suppressed within the scope of investigation, and the corrosion resistance of metal materials is improved.

[0030] Table 1 List of film composition and thickness at different concentrations at 200°C

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com