Control method of special hot rolled sheet to plus pressure

A control method, a reduction control technology, applied in the direction of hydraulic program control, tension/pressure control, rolling force/roll gap control, etc., can solve the problem of mechanical damage of hydraulic pipelines and equipment, affecting the quality and quality of rolled products, Rolling mill frame vibration and other issues, to achieve the effect of ensuring safe operation, improving technology and level, and advanced steel rolling technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1. Control method of variable gain reduction in hot rolling of special steel

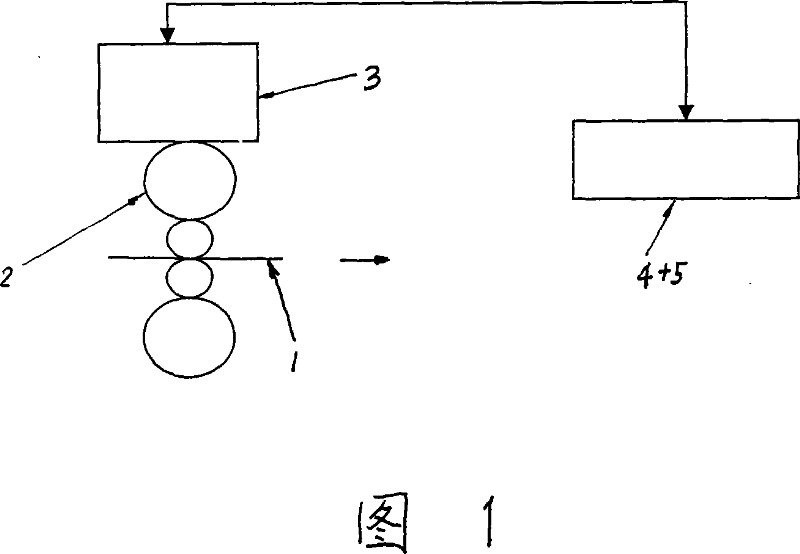

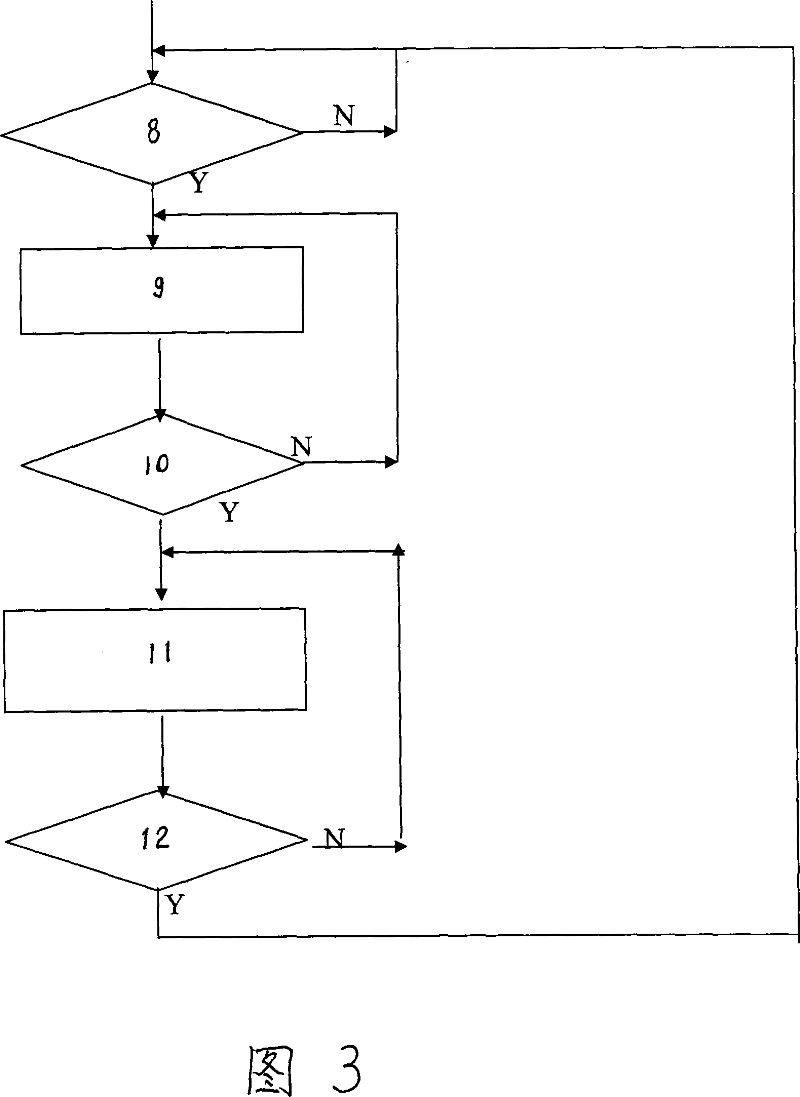

[0021]The control method of special steel hot rolling with variable gain reduction in this embodiment is a control technology for special steel hot rolling with variable gain reduction. This technology is an automatic control technology for hydraulic pressure reduction. The technical characteristics are: The special steel hot rolling variable gain reduction control method is automatically controlled by the computer system and its software program. It is a steel rolling method in which the special steel strip is rolled by the finishing mill to realize the variable gain reduction control, that is, the hydraulic system reduction New technology of automatic variable gain control. Fig. 1 shows the overall schematic diagram of the control method of the variable gain reduction of the special steel hot continuous rolling of this example, in Fig. 1: the rolled strip steel 1 passes through t...

Embodiment 2

[0022] Embodiment 2. Control method of variable gain reduction in hot rolling of special steel

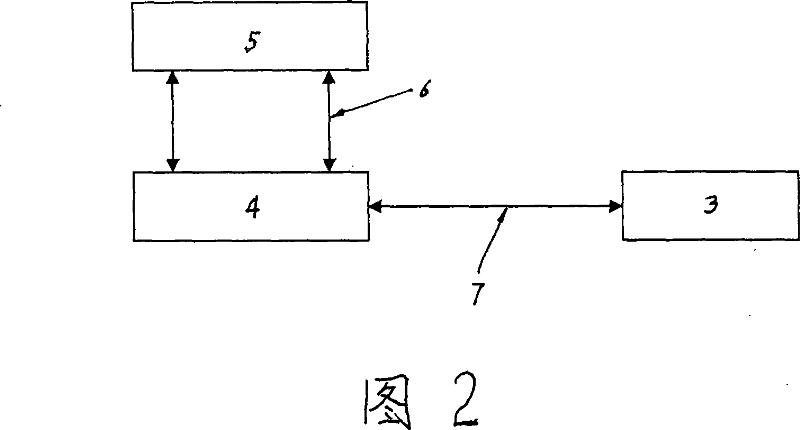

[0023] The general situation of the control method of the special steel hot rolling with variable gain reduction in this embodiment can be shown in conjunction with FIGS. 1 to 3 . The difference between the control method of the special steel hot rolling variable gain reduction of this example and embodiment one has: 1. the computer control system of this example is at least the system that is made up of two-stage (parameter management level 5 and rolling mill control level 4) computers 2. the series parameter setting of this example is to carry out parameter setting and realize automatic control according to the rolled steel grade different from embodiment one—as stainless steel and specification thereof, the specific content of described series parameter setting can be compared Or refer to Table 1, no need to repeat; 3. Depression position X in this example n Still according to ...

Embodiment 3

[0024] Embodiment 3. Control method of variable gain reduction in hot rolling of special steel

[0025] The general situation of the control method of variable gain reduction in special steel hot rolling in this embodiment is basically the same as that described in Embodiment 1 and Embodiment 2. The control method of the special steel hot rolling variable gain reduction of this example has the difference with embodiment one and embodiment two: 1. the computer control system of this example is composed of multiple levels (comprising parameter management level 5 and rolling mill control level 4) A system composed of computers; 2. the series of parameter setting of this example is based on different rolled steel grades from embodiment one and embodiment two—such as silicon steel and its specifications, which carry out parameter setting and realize automatic control. The specific content of the parameter setting can be compared or referred to Table 1, and will not be repeated; 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com