Varistor with novel short-circuit protection device

A short-circuit protection, varistor technology, applied in the direction of varistor, current-responsive resistor, etc., to achieve the effect of complex structure, high inductance and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

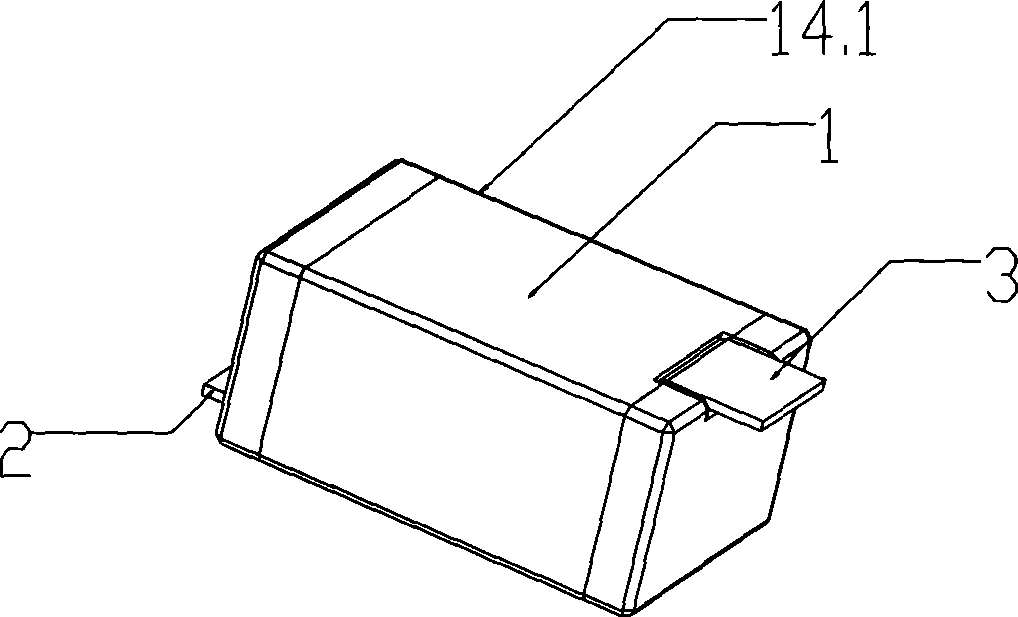

[0075] see figure 1

[0076] figure 1 It is a perspective view of the short circuit protection device in the present invention. exist figure 1 Among them, the varistor body 14 with the short-circuit protection device 14.1 includes an insulator matrix body 1, and the electrodes 2 and 3 protrude from both ends of the insulator matrix body 1 of the short-circuit protection device 14.1, and the electrode 3 has The function of heat transfer, conduction and fixed short-circuit protection device 14.1, the electrode 2 is used to be connected with the lead-out pin 13 of the piezoresistor body 14 (such as Figure 4 shown).

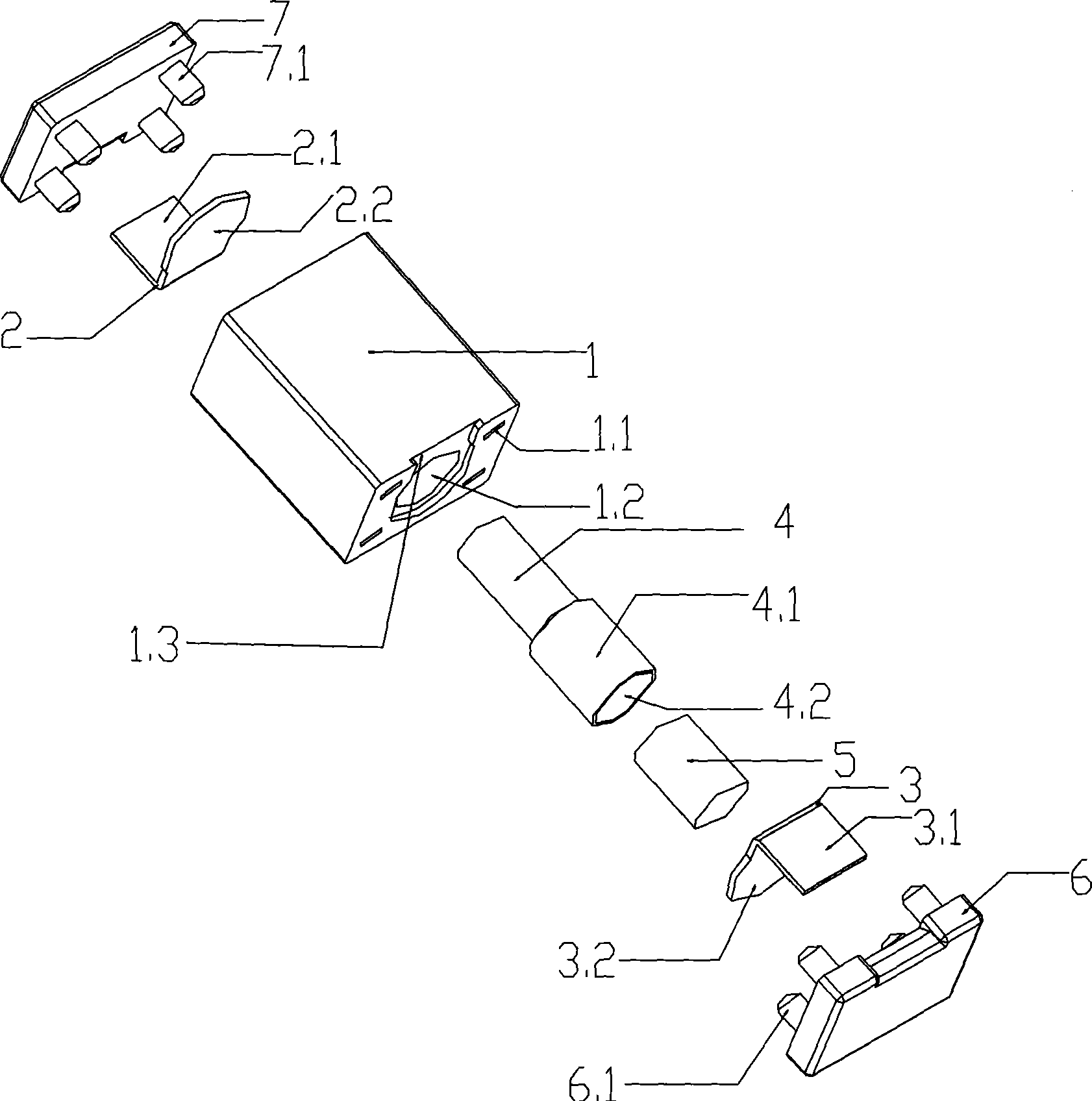

[0077] see figure 2

[0078] figure 2 It is an assembly diagram of components of the short-circuit protection device in the present invention. exist figure 2 Among them, the insulator matrix body 1 and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com