Synthesis method of valsartan

A synthesis method and valine technology, applied in directions such as organic chemistry, can solve the problems of high toxicity of trialkyltin azide, high cost, unreported chiral purity of valsartan, etc., and achieve easy industrial operation, The effect of stable raw materials and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

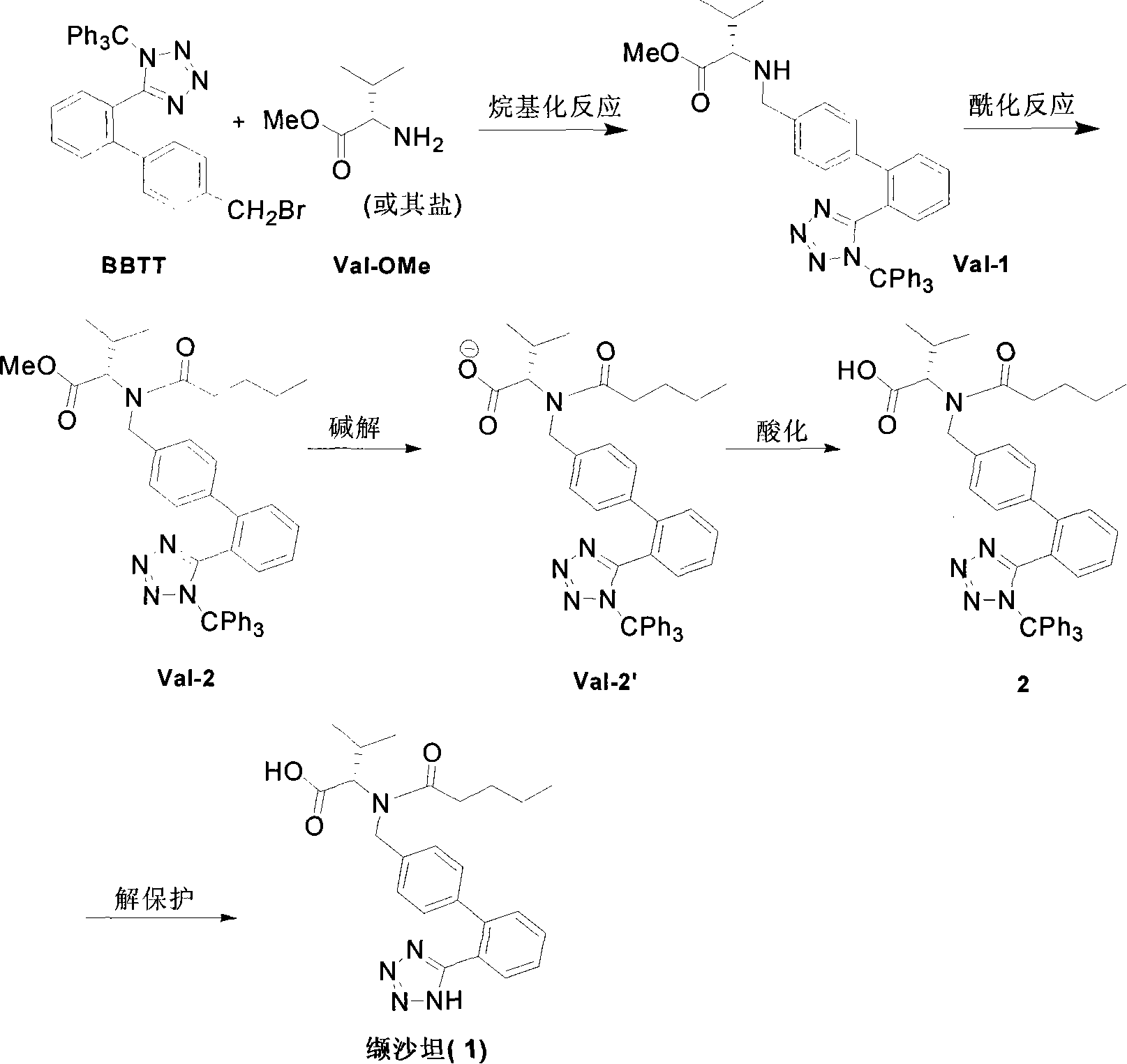

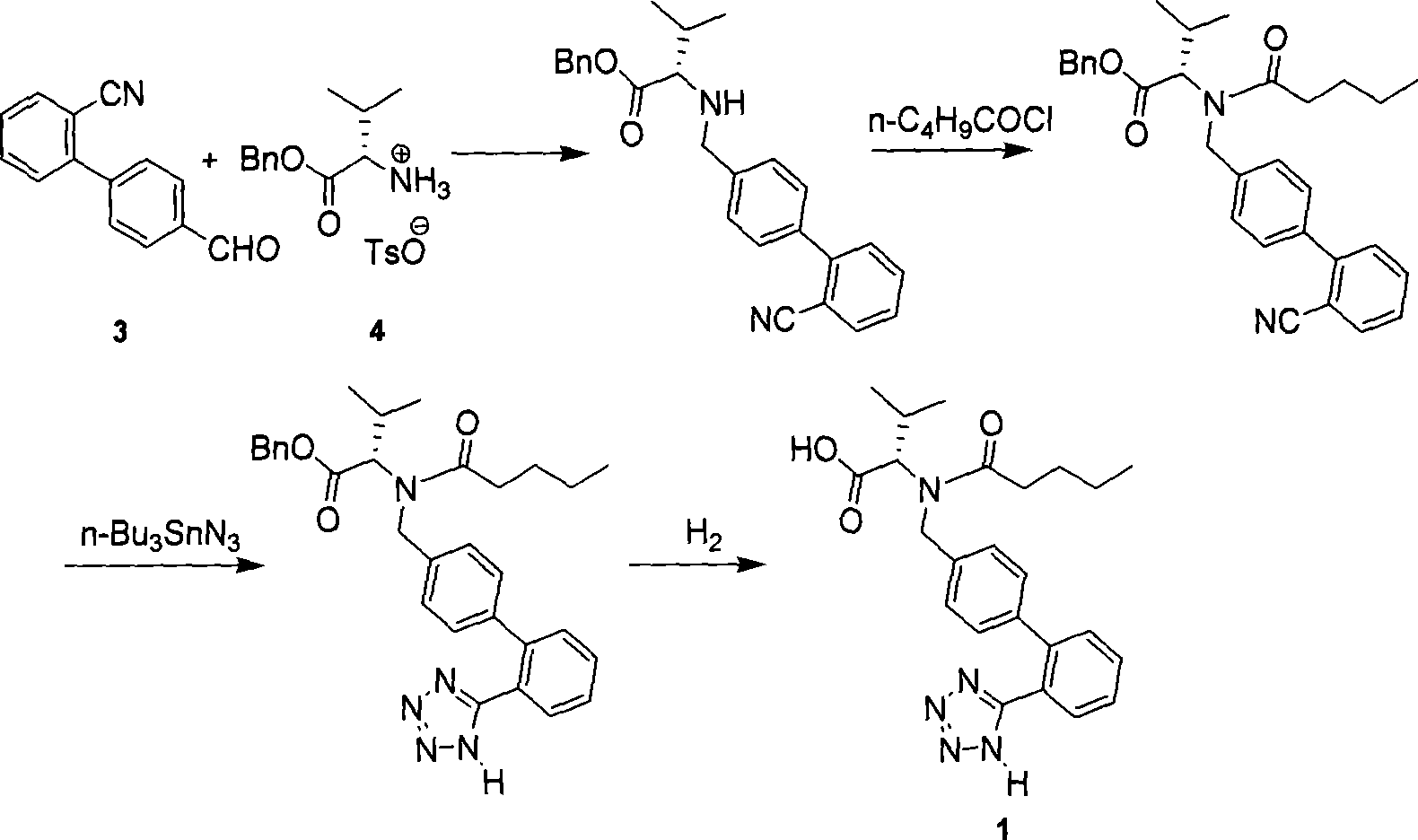

Method used

Image

Examples

example 1

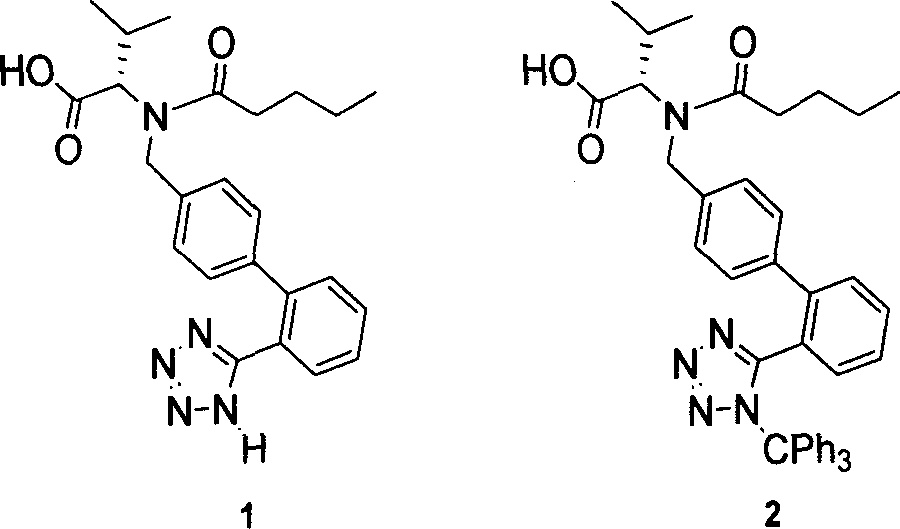

[0035]Example 1. N-[[2'-(N'-trityl-tetrazol-5-yl)-(1,1'-diphenyl)-4-yl]-methyl]-L- Preparation of valine methyl ester (Val-1)

[0036] In a 1000mL four-neck flask equipped with a drying tube, a thermometer, a dropping funnel and a mechanical stirring paddle, add valine methyl ester (Val-OMe, 24.3g, 0.185mol), diisopropylethylamine (18.7g, 0.185mol), and dichloromethane (300mL), stir to dissolve, and cool down. At -10~0°C, a solution of N-trityl-2'-tetrazolyl-4-bromomethylbiphenyl (BBTT, 100g, 0.179mol) in dichloromethane (300mL) was added dropwise, and Complete, at 0-10 DEG C, continue to react for 4 to 5 hours, TLC (developing solvent, n-hexane: ethyl acetate = 5: 1) shows that the raw material basically disappears, add 5% sodium bicarbonate aqueous solution to wash, and saturated brine to wash , the organic phase was decompressed to remove dichloromethane to obtain N-[[2'-(N'-trityl-tetrazol-5-yl)-(1,1'-diphenyl)-4- Base]-methyl]-L-valine methyl ester crude product 110g (...

example 2

[0037] Example 2. N-[[2'-(N'-trityl-tetrazol-5-yl)-(1,1'-diphenyl)-4-yl]-methyl]-L- Preparation of valine methyl ester (Val-1)

[0038] In a 100mL three-neck flask equipped with a drying tube, a thermometer, and a dropping funnel, add valine methyl ester hydrochloride (Val-OMe hydrochloride, 3.1g, 18.5mmol), diisopropylethylamine (3.74g , 37mmol), and dichloromethane (30mL), stirring and dissolving, cooling down. At -10~0°C, add N-trityl-2'-tetrazolyl-4-bromomethylbiphenyl (BBTT, 9.98g, 0.179mol) in dichloromethane (30mL) dropwise, After the addition was completed, the reaction was continued for about 5 hours at 0-10° C., TLC showed that the raw materials basically disappeared, and 5% aqueous sodium bicarbonate solution was added for washing, followed by washing with saturated brine, and the organic phase was decompressed to remove dichloromethane to obtain N-[ Crude product of [2'-(N'-trityl-tetrazol-5-yl)-(1,1'-diphenyl)-4-yl]-methyl]-L-valine methyl ester 12.1g, the crud...

example 3

[0039] Example 3. N-(1-oxopentyl)-N-[[2'-(N'-trityl-tetrazol-5-yl)-(1,1'-diphenyl)-4 Preparation of -yl]-methyl]-L-valine methyl ester (Val-2)

[0040] In a 1000mL four-neck flask equipped with a drying tube, a thermometer, a dropping funnel and a mechanical stirrer, add the crude product obtained in Example 1, ethyl acetate (500mL), and triethylamine (21.2g, 0.21mol) after stirring and dissolving , cooled to about -10°C, and slowly added n-valeryl chloride (24.2 g, 0.20 mol) dropwise. After the addition was completed, the reaction was carried out at this temperature for 3 hours; then the temperature was raised, and the reaction was continued at 35° C. for 5 hours, and TLC showed that the reaction was complete. The reaction solution was washed successively with saturated saline, phosphate buffer (pH=7), and deionized water, dried over anhydrous sodium sulfate, and concentrated under reduced pressure to obtain N-(1-oxopentyl)-N-[[2'- (N'-trityl-tetrazol-5-yl)-(1,1'-diphenyl)-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com