Method for preparing mullite from gangue

A coal gangue and mullite technology, which is applied in the field of calcining coal gangue to prepare mullite, can solve the problems of large cost investment and high energy consumption, and achieve the effects of reducing energy consumption, reducing requirements, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

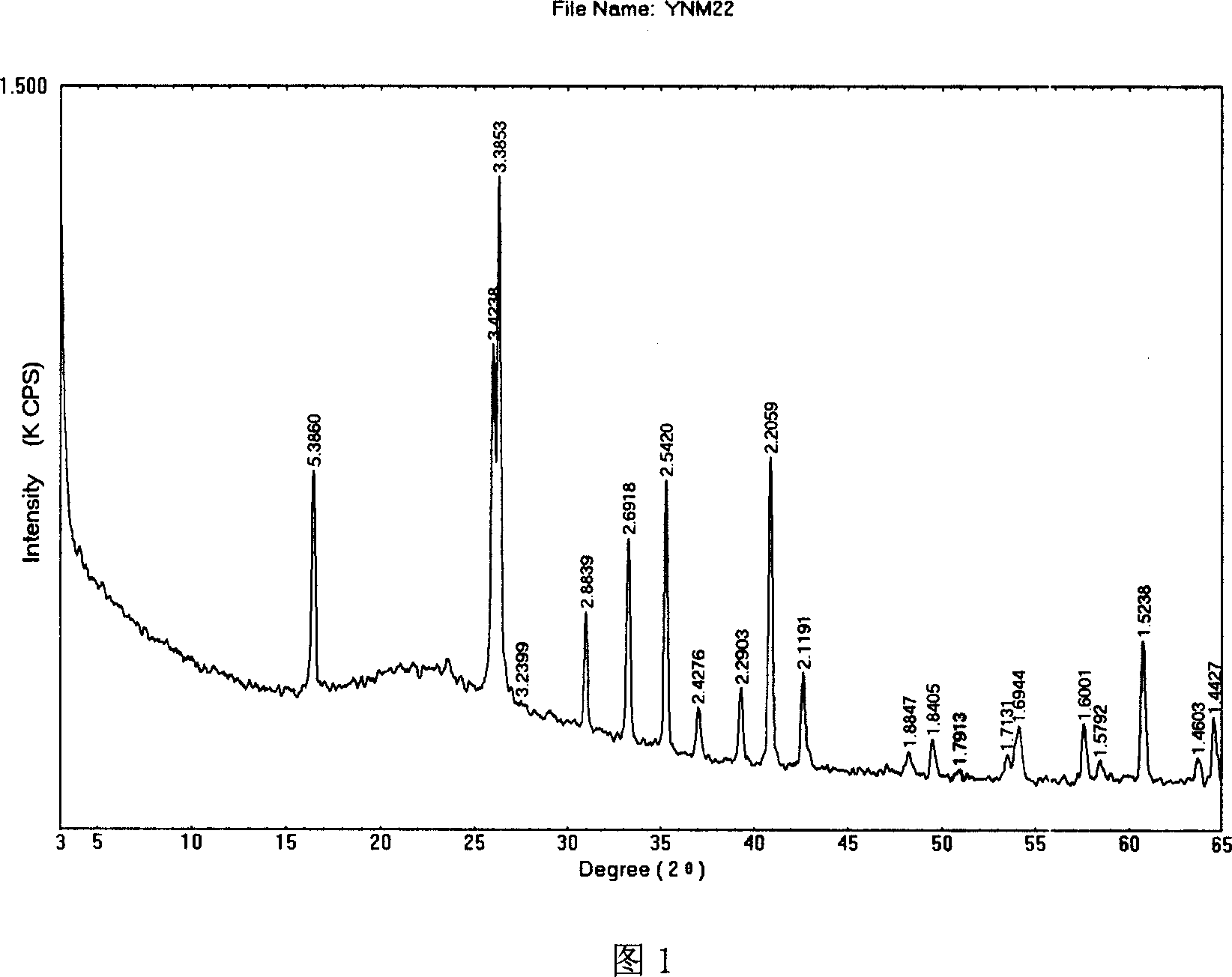

[0023] Get Yidu coal gangue powder (less than 200 mesh) 3.00g, add the sodium fluoride of coal gangue powder quality 15‰, add the lanthanum oxide of coal gangue powder quality 5‰, mix evenly, put into corundum crucible, put The crucible was placed in a silicon-molybdenum rod box-type resistance furnace, the temperature was raised to 1300°C at a rate of 4°C per minute, and the XRD pattern was obtained by calcination at 1300°C for 3 hours. From the X-ray diffraction pattern (Fig. 1) of the sample, it can be seen that the mullite phase is 55-60%, does not contain cristobalite, and the others are amorphous phases.

Embodiment 2

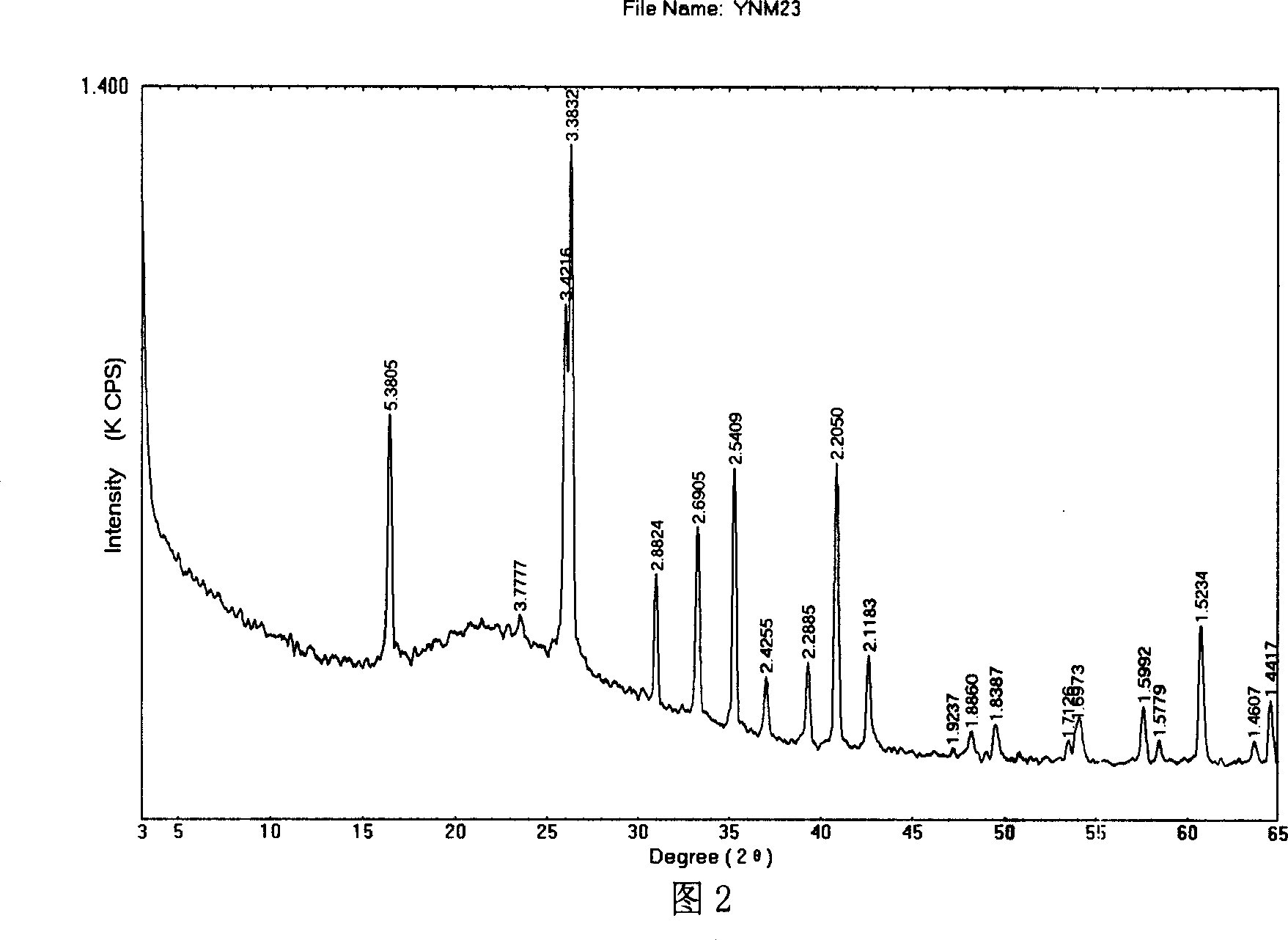

[0025] Get 3.00g of Yidu coal gangue powder (less than 200 mesh), add sodium fluoride with a coal gangue powder quality of 15‰, add lanthanum oxide with a coal gangue powder quality of 3‰, mix evenly, put it in a corundum crucible, and put The crucible was placed in a silicon-molybdenum rod box-type resistance furnace, the temperature was raised to 1300°C at a rate of 4°C per minute, and the XRD pattern was obtained by calcination at 1300°C for 3 hours. From the X-ray diffraction pattern (Fig. 2) of the sample, it can be seen that the mullite phase is 55-60%, does not contain cristobalite, and the others are amorphous phases.

Embodiment 3

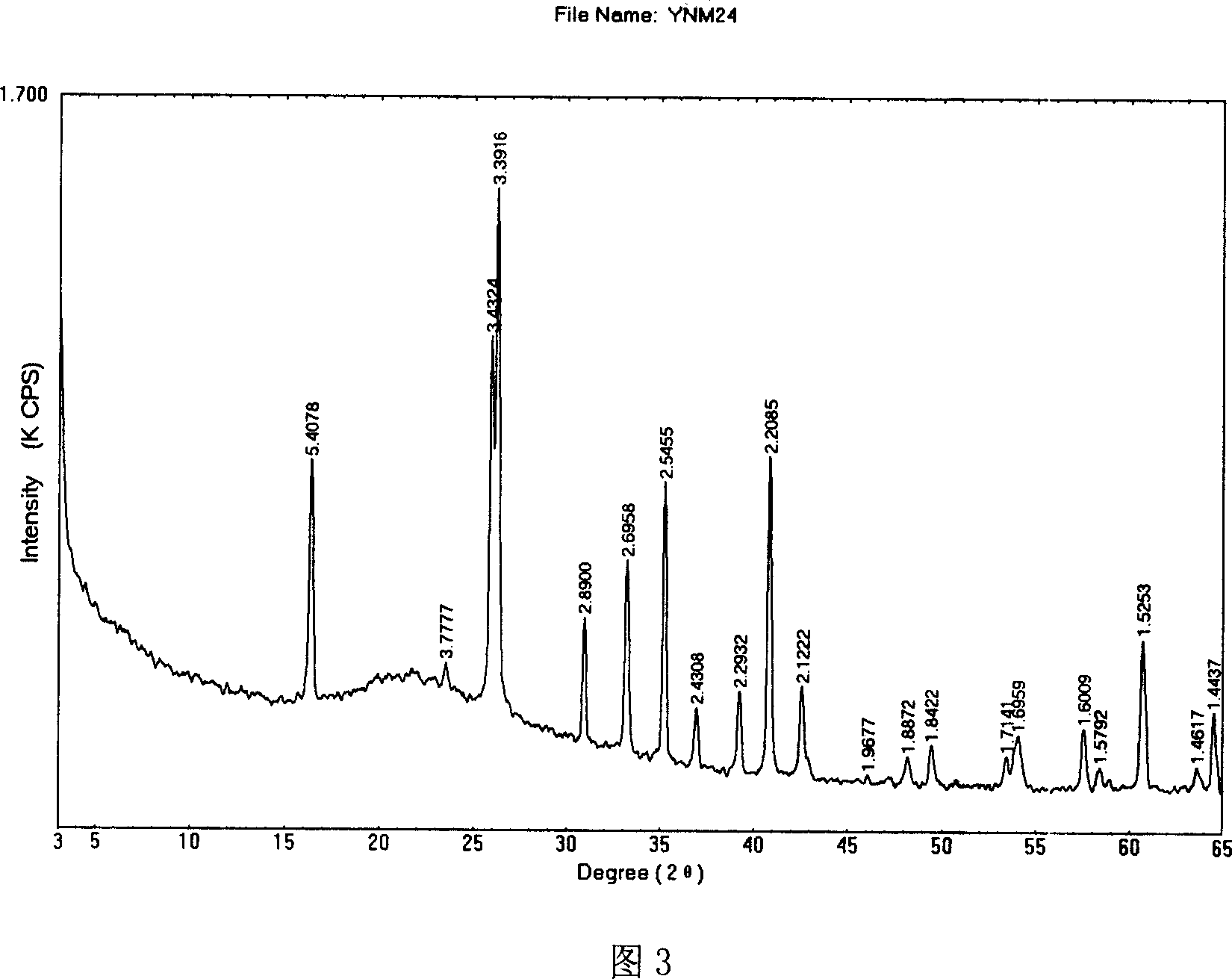

[0027] Get 3.00g of Yidu coal gangue powder (less than 200 mesh), add sodium fluoride with a quality of coal gangue powder of 18‰, add lanthanum oxide with a quality of coal gangue powder of 2‰, mix evenly, put it in a corundum crucible, and put The crucible was placed in a silicon-molybdenum rod box-type resistance furnace, the temperature was raised to 1300°C at a rate of 4°C per minute, and the XRD pattern was obtained by calcination at 1300°C for 3 hours. From the X-ray diffraction pattern (Fig. 3) of the sample, it can be seen that the mullite phase is 55-60%, does not contain cristobalite, and the others are amorphous phases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com