Surface-mounting ceramic electronic component

A technology for ceramic electronic components and electronic components, which is applied to electrical components, resistor components, fixed capacitor components, etc., and can solve problems such as cracks, lack of ductility, and difficulty in resisting impact wiring substrate deflection and falling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

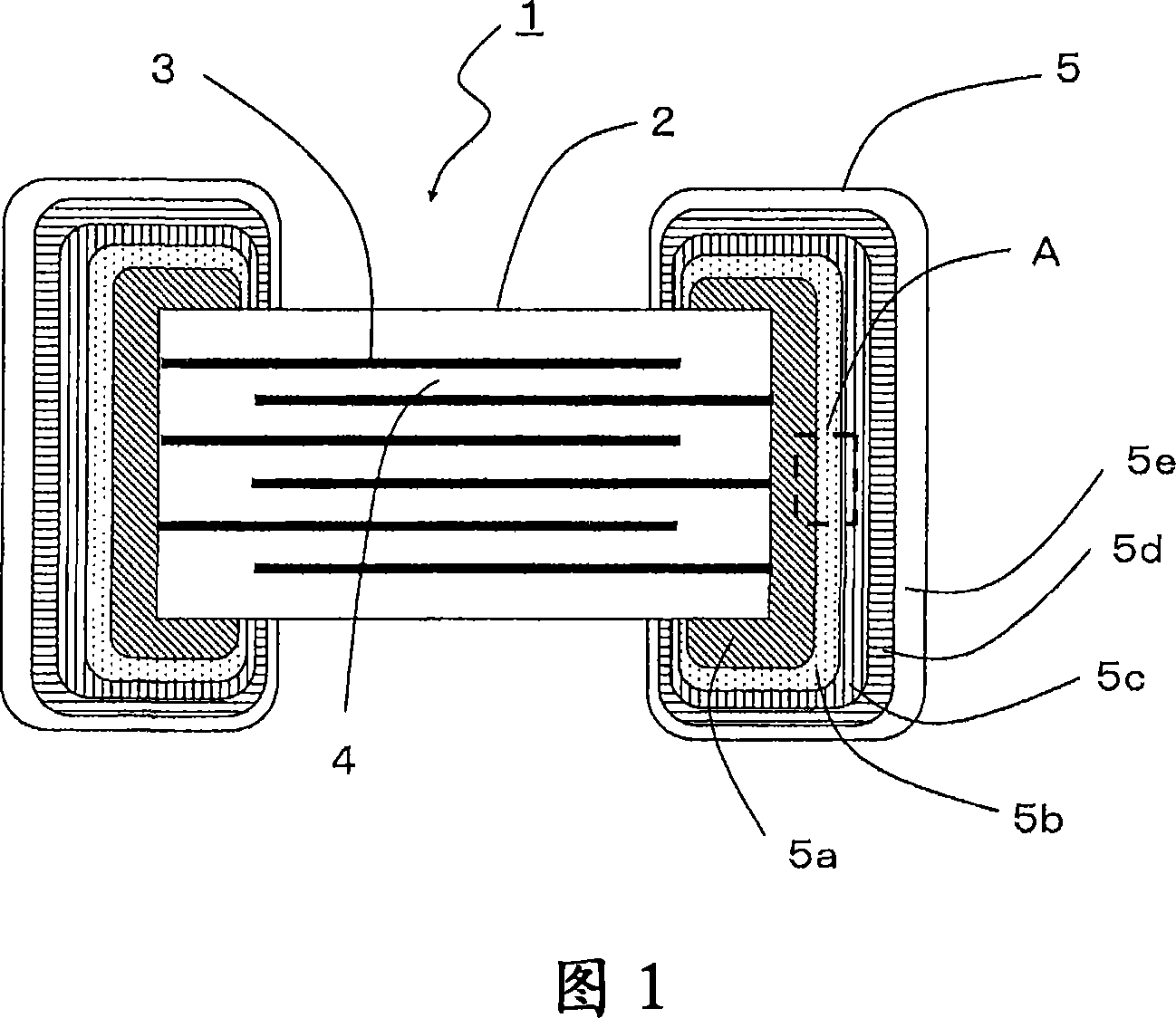

[0034] Dielectric ceramic powder having temperature characteristics representing JIS BJ characteristics was mixed with polyvinyl butyral, its additives, and a solvent to form a mixed slurry, which was formed into a ceramic green sheet having a thickness of 5 μm by a doctor blade. Next, a Ni conductive paste was applied by screen printing on the ceramic green sheet to form internal electrodes. This ceramic green sheet was punched out to a predetermined size, stacked so that the internal electrodes had 10 layers, and bonded by thermocompression to obtain a laminated body. This laminated body was cut into a size of 4.0×2.0 mm. Dip-coat the Ni conductive paste containing the common material on the exposed surface of the internal electrode of the cut laminate, and sinter it in a nitrogen-hydrogen gas at 1300°C to obtain a 3.2×1.6mm-sized substrate with a base metal layer. Multilayer ceramic capacitor basic body.

[0035] A Cu intermediate metal layer having a thickness of 3 μm an...

Embodiment 2

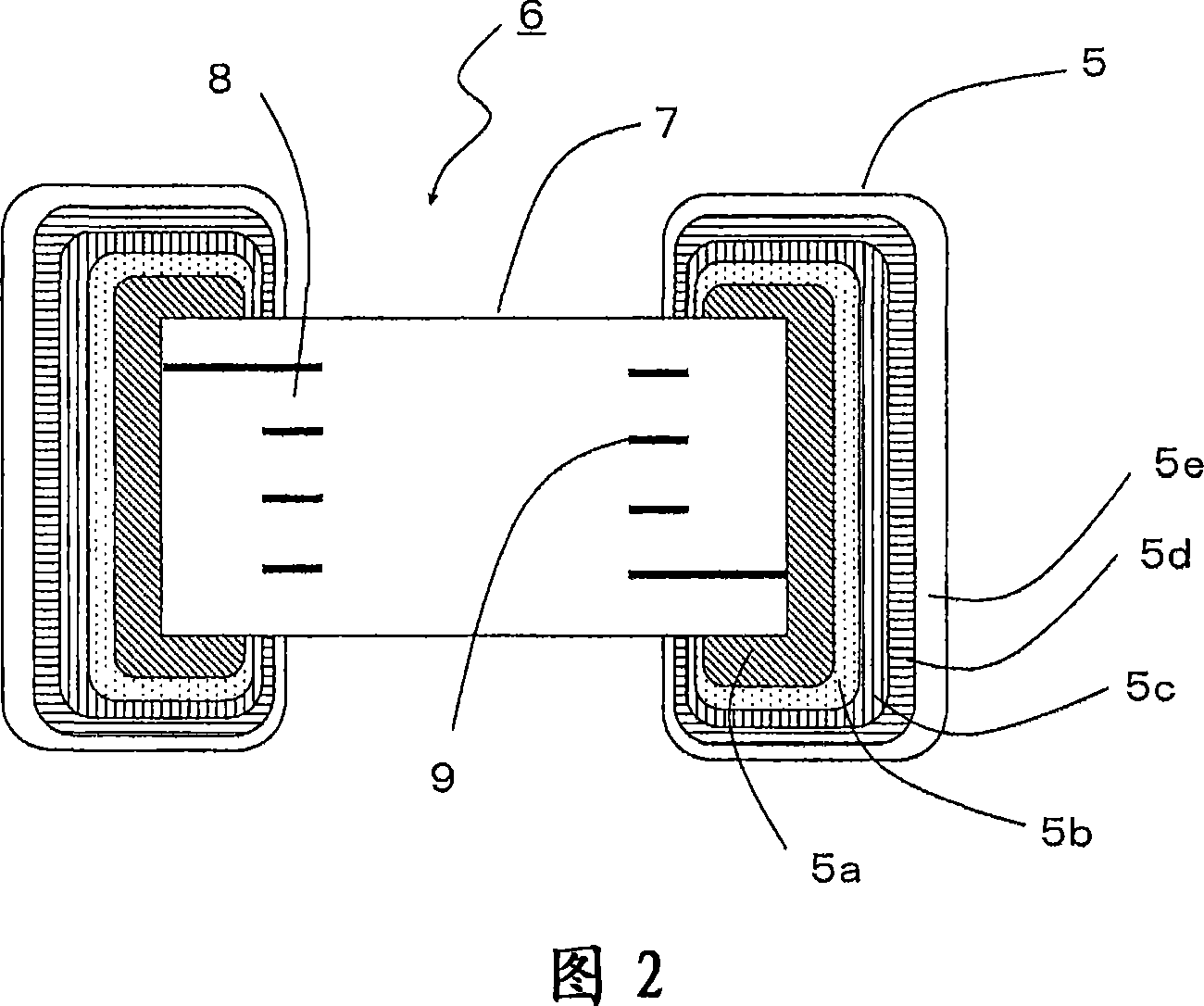

[0037] The same multilayer ceramic capacitor basic body as in Example 1 was prepared, and a Ni intermediate metal layer with a thickness of 3 μm and a continuity rate of 100% was formed on the base metal layer by electrolytic plating. Next, on the Ni intermediate metal layer, the conductive resin filled with Ag in the epoxy resin was impregnated and coated in the same manner as in Example 1, and cured at 200° C. to form a conductive resin layer. A nickel-plated metal layer and a tin-plated metal layer are sequentially formed on the resin layer by electrolytic plating.

Embodiment 3

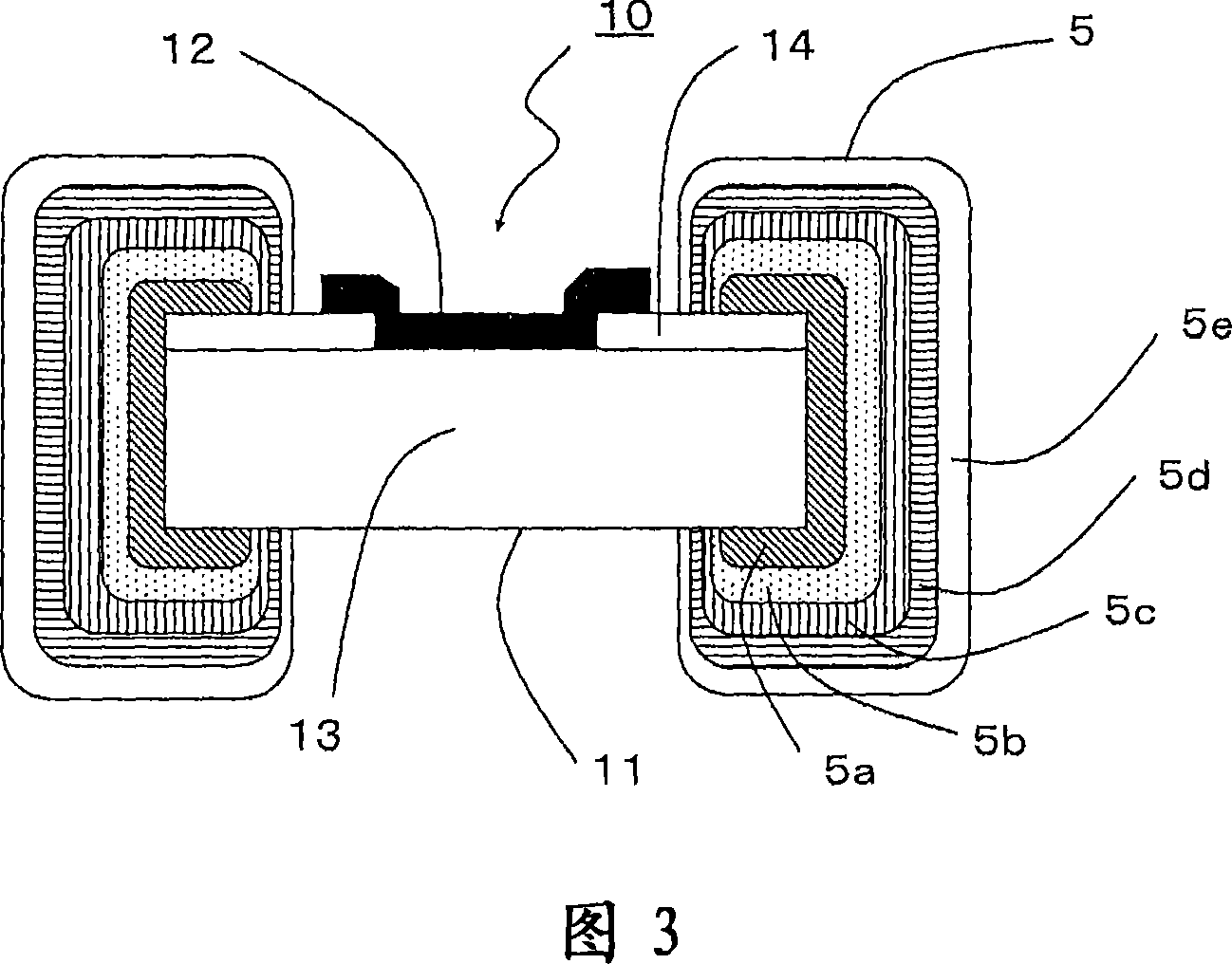

[0044] Prepare the same laminated ceramic capacitor basic body as in Example 1, adjust the plating time on the base metal layer by electrolytic plating, and form Cu intermediate metal layers with film thicknesses of 0.3 μm, 0.5 μm, 1 μm, and 3 μm (continuity ratio: 100 %) of the test material. On the Cu intermediate metal layer of these test materials, a conductive resin layer, a nickel-plated metal layer, and a tin-plated metal layer were sequentially formed in the same manner as in Example 1.

[0045] Ten of these test materials and the test material of Comparative Example 1 were respectively prepared, and a flexure test was performed in accordance with the procedure of JIS-C5101 substrate bending resistance test method. The amount of deflection when the capacitance decreased by 10% or more was measured, and the average value of 10 test materials of each type was calculated. Table 1 shows the results. Even when the amount of deflection was 10 mm, the case where no decrease...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com